Slide-proof braking and positioning device and method for slide-proof braking and positioning

A braking positioning and braking device technology, applied in the direction of lifting devices, etc., can solve the problems of bulky braking devices, insufficient positioning force, and inability to achieve braking, etc., and achieve simple and convenient operation methods, braking force or positioning force Large, good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

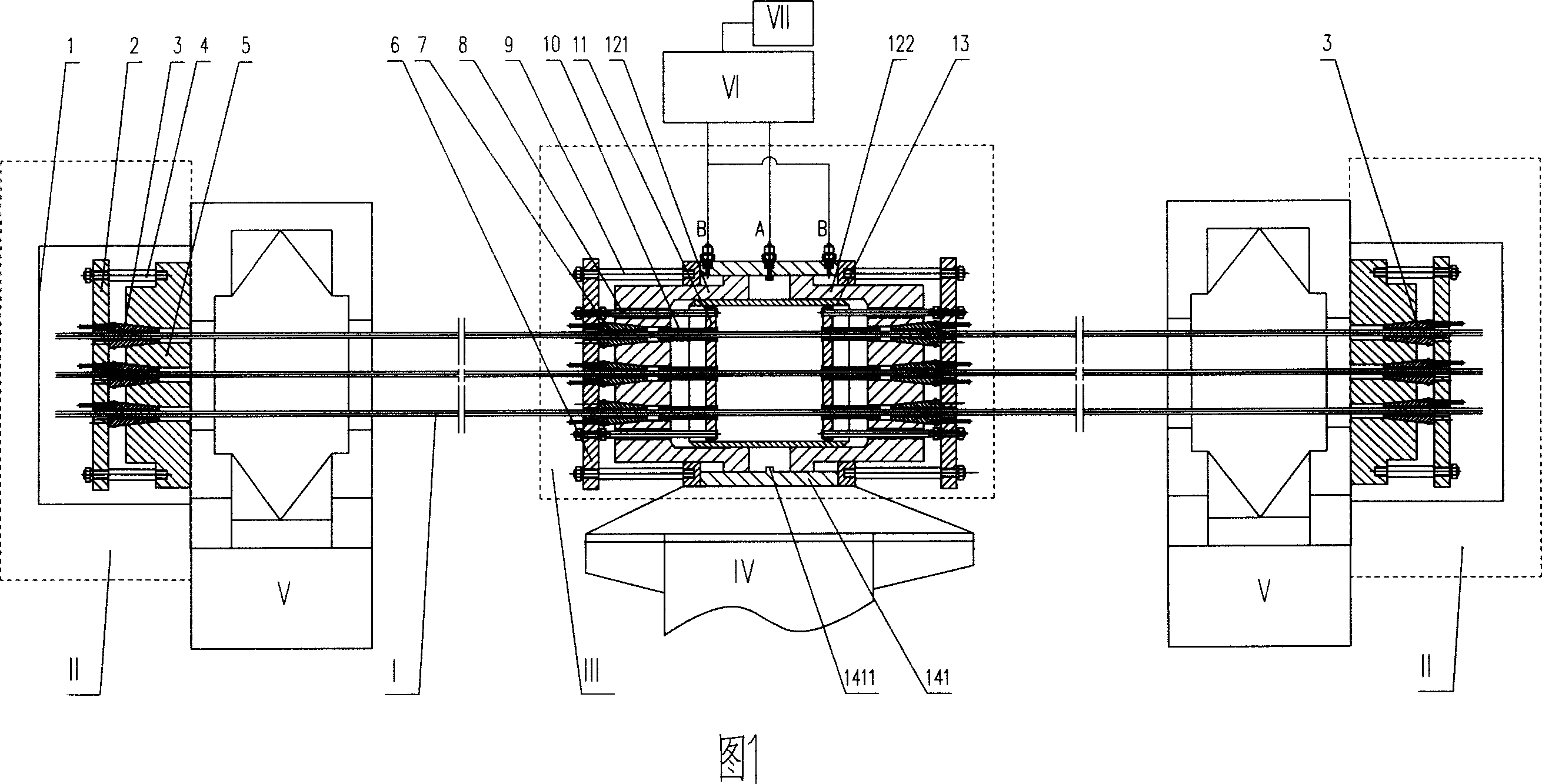

[0041] An anti-slip braking positioning device system, the system is composed of N braking prestressed tendons I and its anchoring device II, braking device III, movable support IV, fixed support V, hydraulic pump station VI and its control system VII The anchoring device II is respectively located at the two ends of the N braking prestressed tendons I, and the braking device III is composed of a brake jack and an anchor loosening device for clamping the prestressed tendons on both sides of the brake jack, The outer wall of the oil cylinder of the brake jack is fixedly connected with the movable support IV, and the N brake prestressed ribs I pass through the anchor holes on the pistons 121, 122 and the anchor loosening device is fixed on the fixed support V in parallel by the anchoring device II. The moving device III is connected with the hydraulic pump station VI through the oil circuit, and the hydraulic pump station VI is connected with the control system VII;

[0042] The...

Embodiment 2

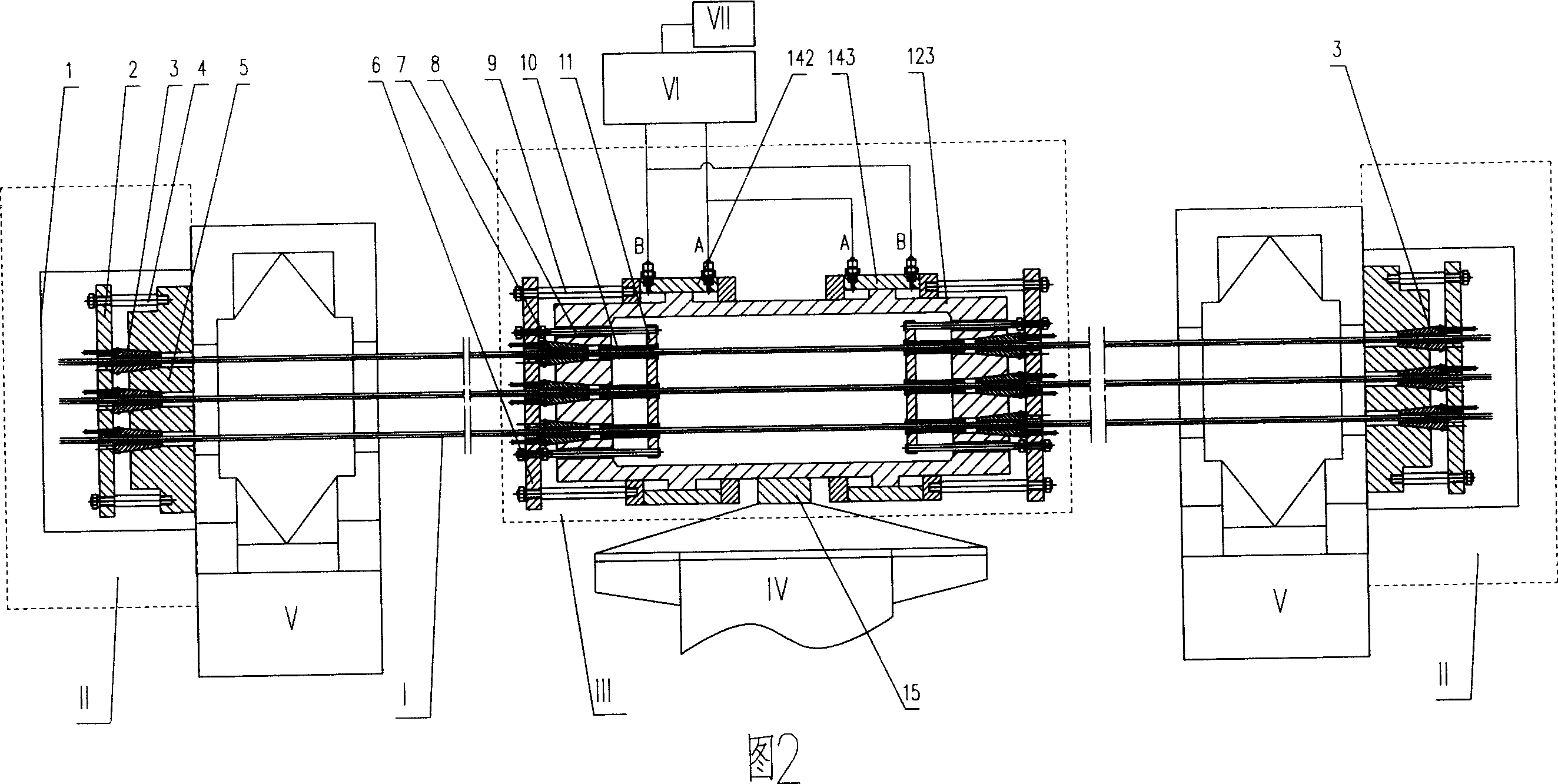

[0046] An anti-slip brake positioning device system, the basic structure of which is the same as that of Embodiment 1, the difference being that the brake jack of the brake device III consists of a piston 123 and two pistons with opposite directions of movement that are sleeved outside the piston 123. Oil cylinders 142, 143 are formed, and there is a connection device 15 in the middle part of the piston outer wall of the brake jack, and the piston is fixedly connected with the movable support IV through the connection device 15 (referring to Fig. 2 ).

Embodiment 3

[0048] The anti-slip braking positioning device system described in the first embodiment above is used in the anti-slip braking or positioning method. It adopts hydraulic prestressing technology to clamp the anchor loosener clamp by controlling the reciprocating movement of the brake jack piston or oil cylinder. Tightening or loosening the prestressed tendons to realize the braking or releasing of large-scale directional mobile equipment or the positioning or releasing of large-scale equipment, it includes the following steps:

[0049] A. System installation:

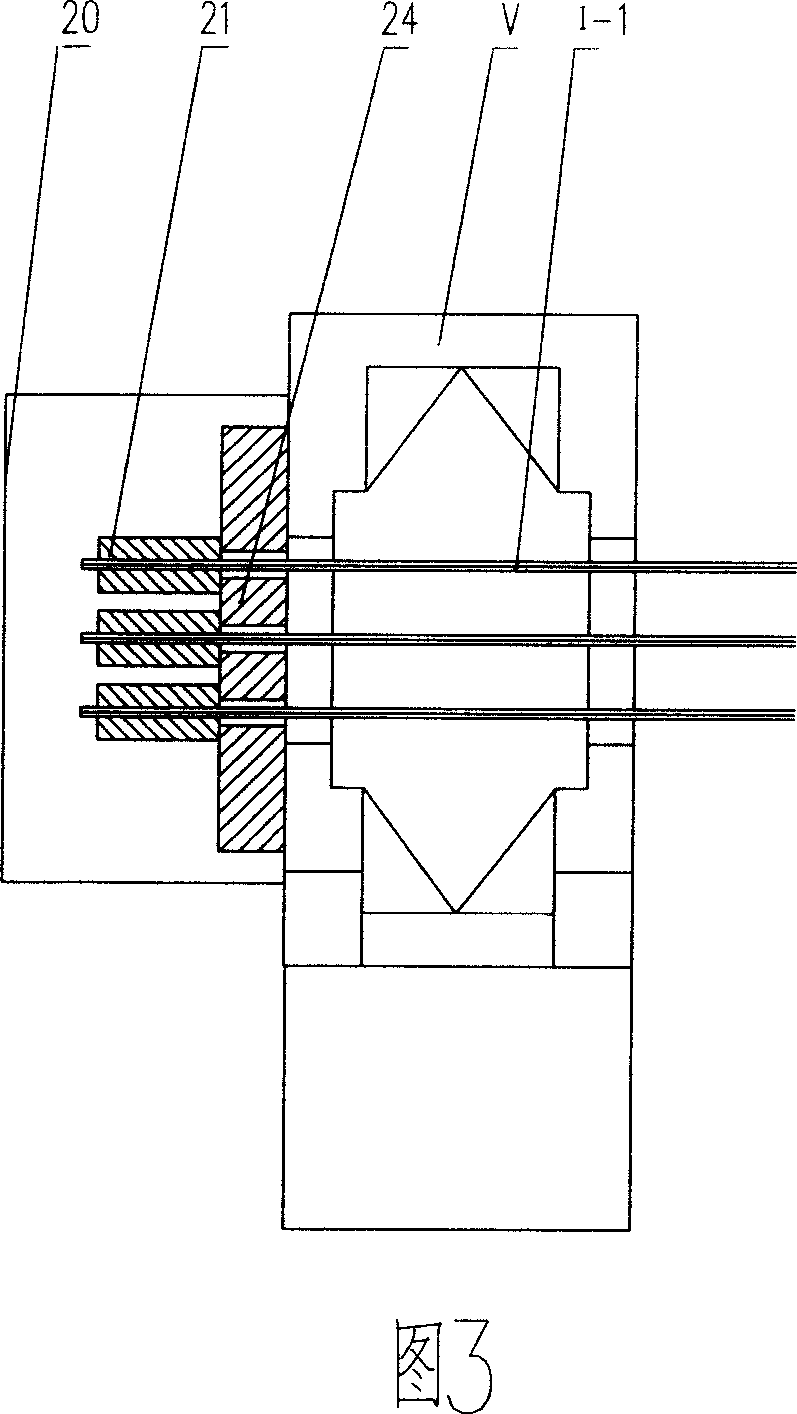

[0050] ①Prepare the fixed support V, the movable support IV and select the positions for the fixed support V, the hydraulic pump station VI and the control system VII;

[0051] ②Connect a certain part of the braked equipment or the positioned equipment with the movable bracket IV;

[0052] ③Fixly connect the oil cylinder 141 of the brake jack of the brake device III with the movable support IV;

[0053] ④Through the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com