Device and method for coal-burning boiler fume ozone oxidation and simultaneous desulfurization and denitrification

A technology of ozone oxidation, desulfurization and denitrification, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problem of high energy consumption and achieve the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

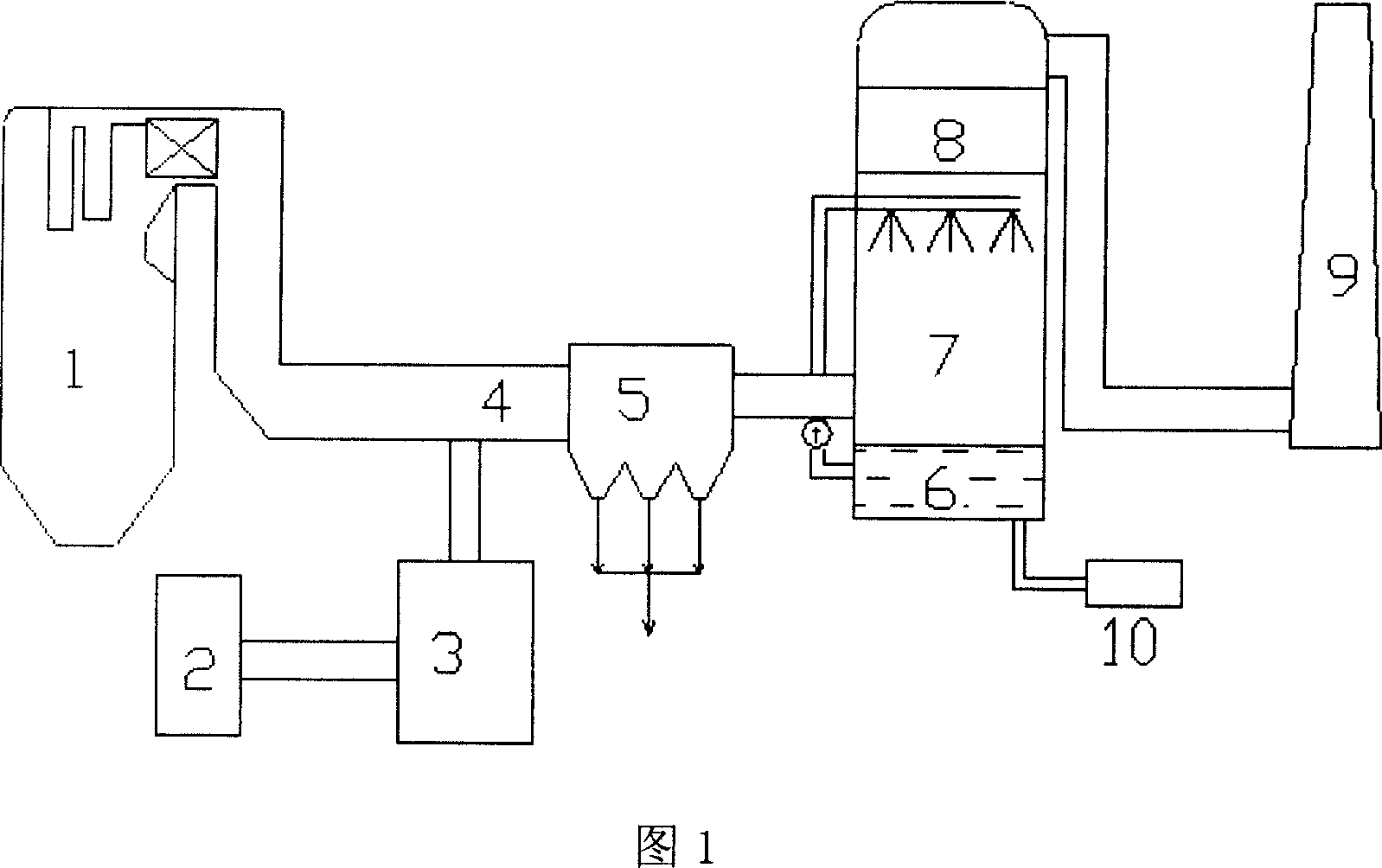

[0025] Layout scheme I for simultaneous desulfurization and denitrification by ozone oxidation of coal-fired boiler flue gas is shown in Figure 1. After the air is dried and purified, it is sent to the dry and filtered oxygen generator, and the generated oxygen is sent to the ozone generating device to prepare high-concentration ozone. The injection amount is adjusted from time to time according to the concentration of nitrogen oxides in the flue gas, and the molar ratio of ozone to nitrogen oxides is 1.1:1 to ensure a reaction time of at least 0.5s. The nozzle adopts porous grid injection, and the injection position is 1m away from the flue gas outlet of the air preheater. The treated flue gas enters the wet scrubber after passing through the electrostatic precipitator, and the absorption liquid is recycled. The flue gas is sent to the chimney after being treated by the wet scrubber and demister, and the absorbed sulfate and nitrate are concentrated and crystallized. The was...

Embodiment 2

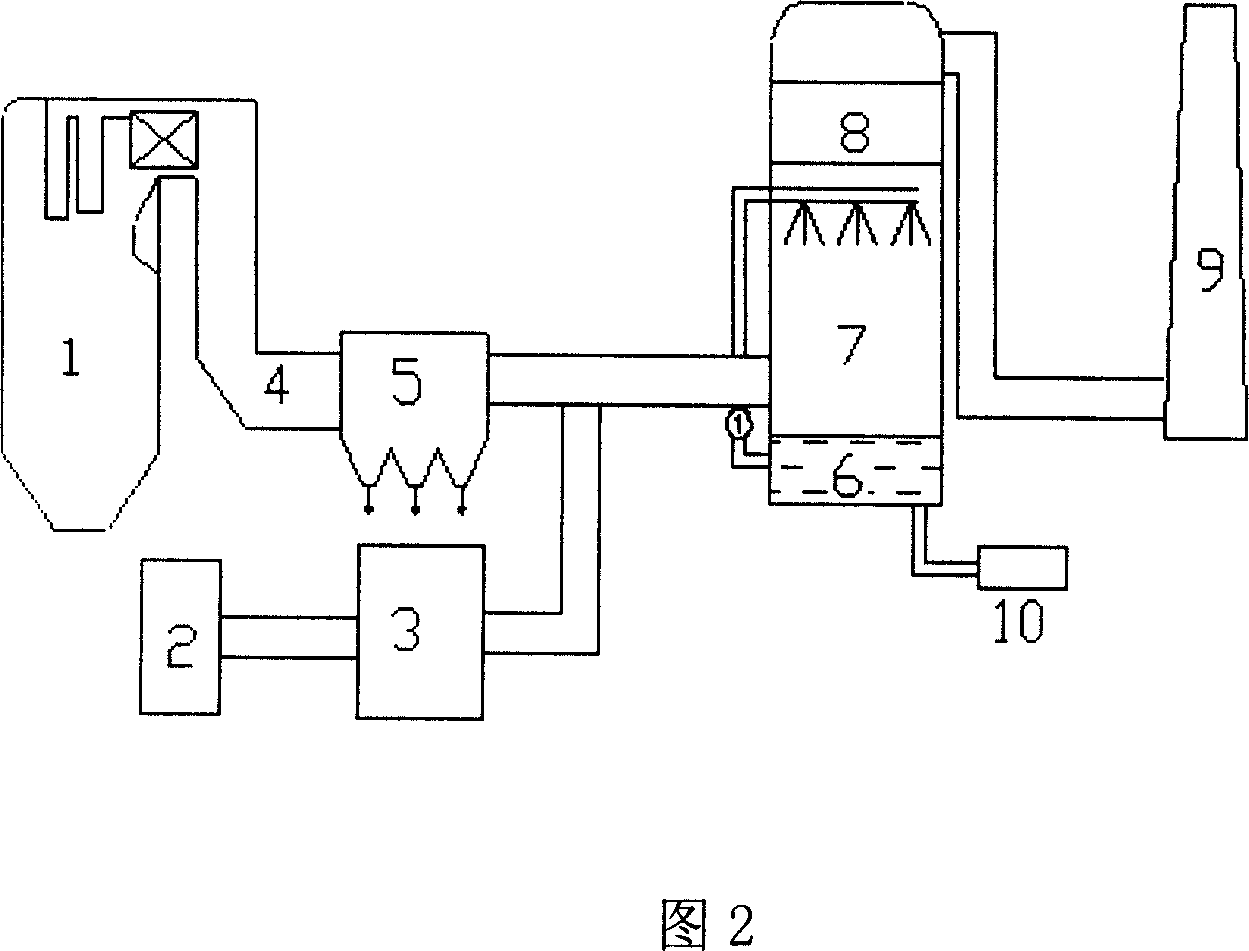

[0027]Coal-fired boiler flue gas ozone oxidation and simultaneous desulfurization and denitrification scheme II, as shown in Figure 2. Send ozone into the low-dust flue gas environment at about 110°C after the electrostatic precipitator. The amount of ozone injected is dynamically adjusted according to the concentration of nitrogen oxides in the flue gas, and the molar ratio of ozone to nitrogen oxides is 1.0. The position of the injection point is guaranteed to be away from the washing machine The residence time at the tower entrance is more than 0.5s. Ozone is sprayed in a porous grid shape. The oxidized flue gas enters the lye washing tower for absorption, and the absorption liquid is recycled. After the flue gas is washed and defogged, it is sent to the chimney for discharge, and the absorbed sulfate and nitrate are concentrated. Crystallization treatment. The washing tower uses lye as the absorbent, and the washing tower is a spray tower or a packed tower. The lye used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com