Floor panel

A floor and support plate technology, applied in the field of floor panels, can solve problems such as wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

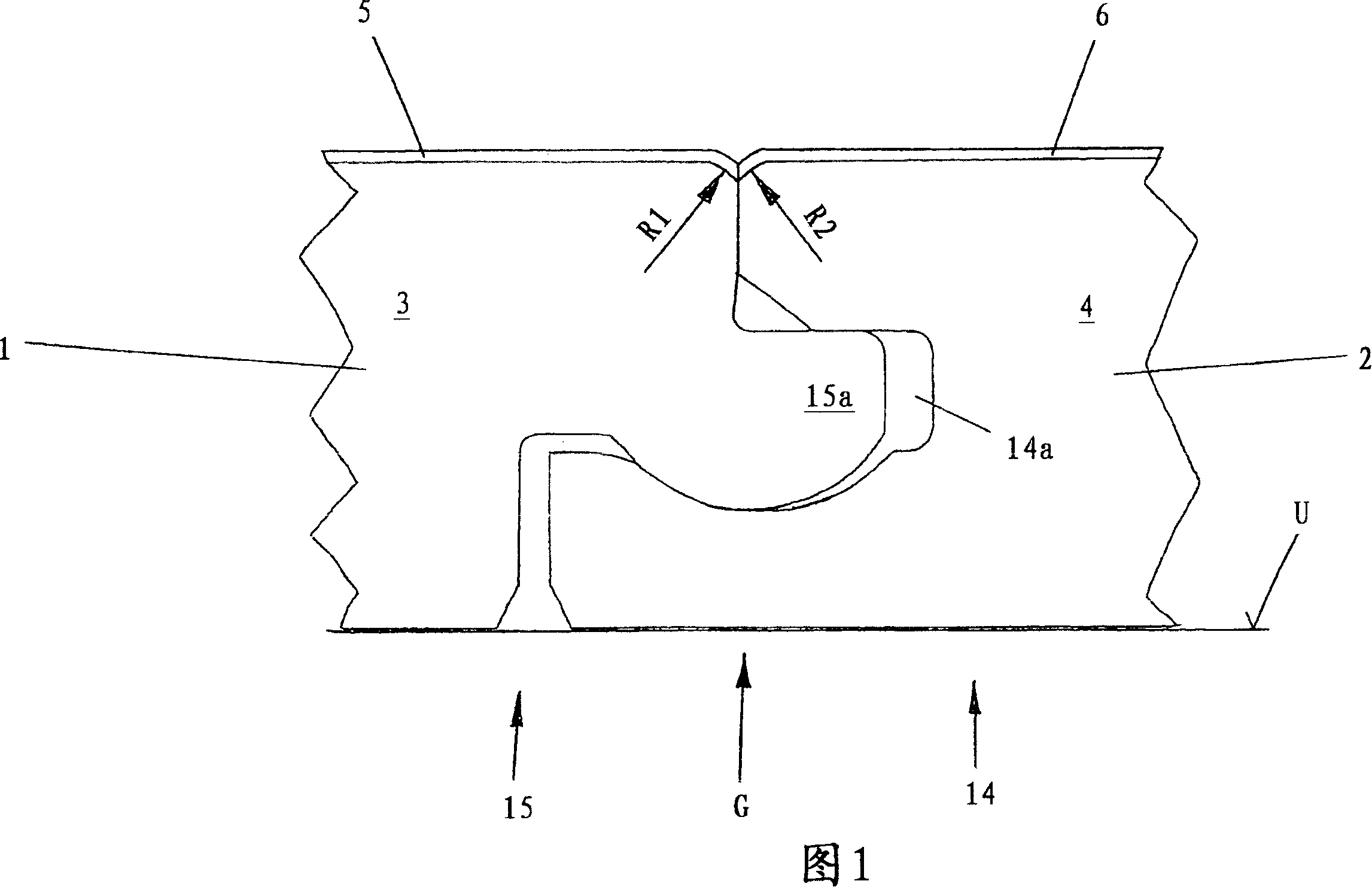

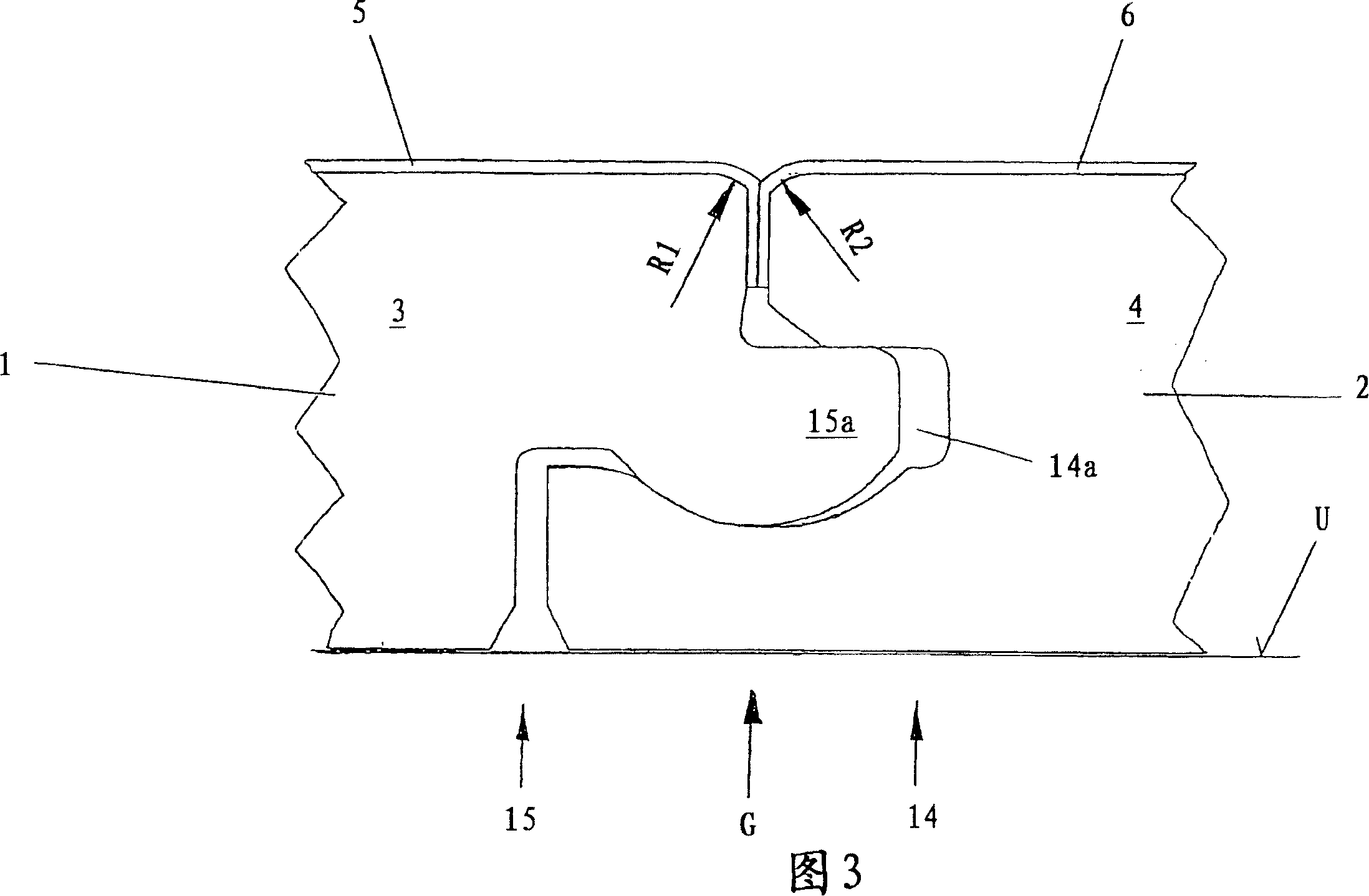

[0033] FIG. 1 shows two interlocking floor panels 1 and 2 according to the invention. Each floor panel 1 or 2 has complementary interlocking profiles on opposite edges, so that the profile of one edge of the floor panel matches the profile of the opposite edge so that it is always possible A similar floor panel is fastened to the laid floor panel. The floor panel 1 therefore has a groove profile (not shown) on the edge facing away from the tongue profile 15 , while the floor panel 2 has a groove profile (not shown) opposite its groove surface 14 .

[0034] The two floor panels 1 and 2 have a carrier plate 3 or 4 on which a service floor 5 or 6 is arranged.

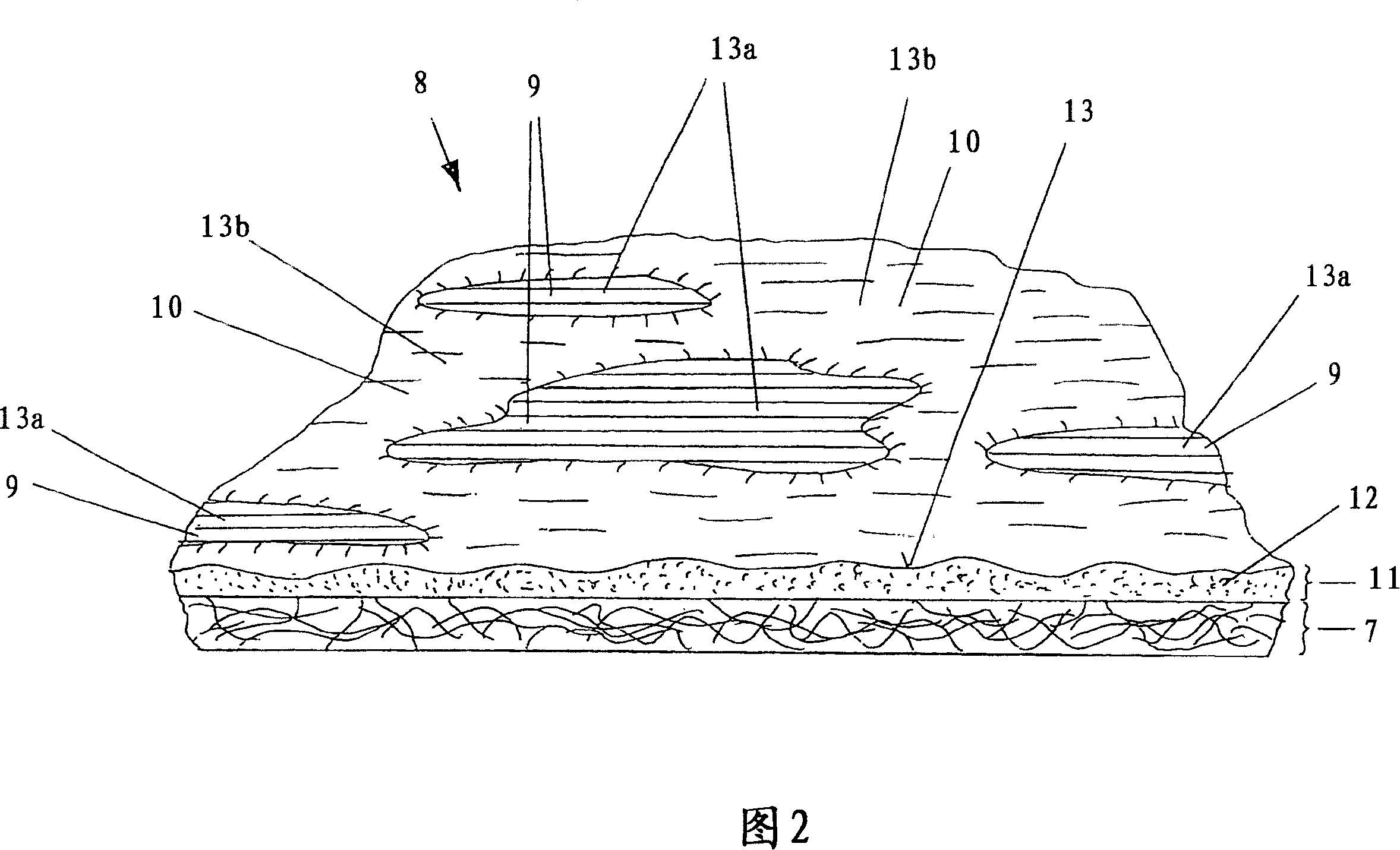

[0035] In order to illustrate the structure of the use layer 5 or 6, FIG. 2 schematically shows part of the use layer. Accordingly, the layer used is paper 7 which is printed with a decorative pattern 8 and which can be referred to as patterned decorative paper 7 . The pattern pattern 8 is divided into different pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com