Method and device for producing staple fibers

A short fiber and spinning device technology, applied in the field of short fiber manufacturing, can solve the problems of low manufacturing capacity and achieve the effect of short replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

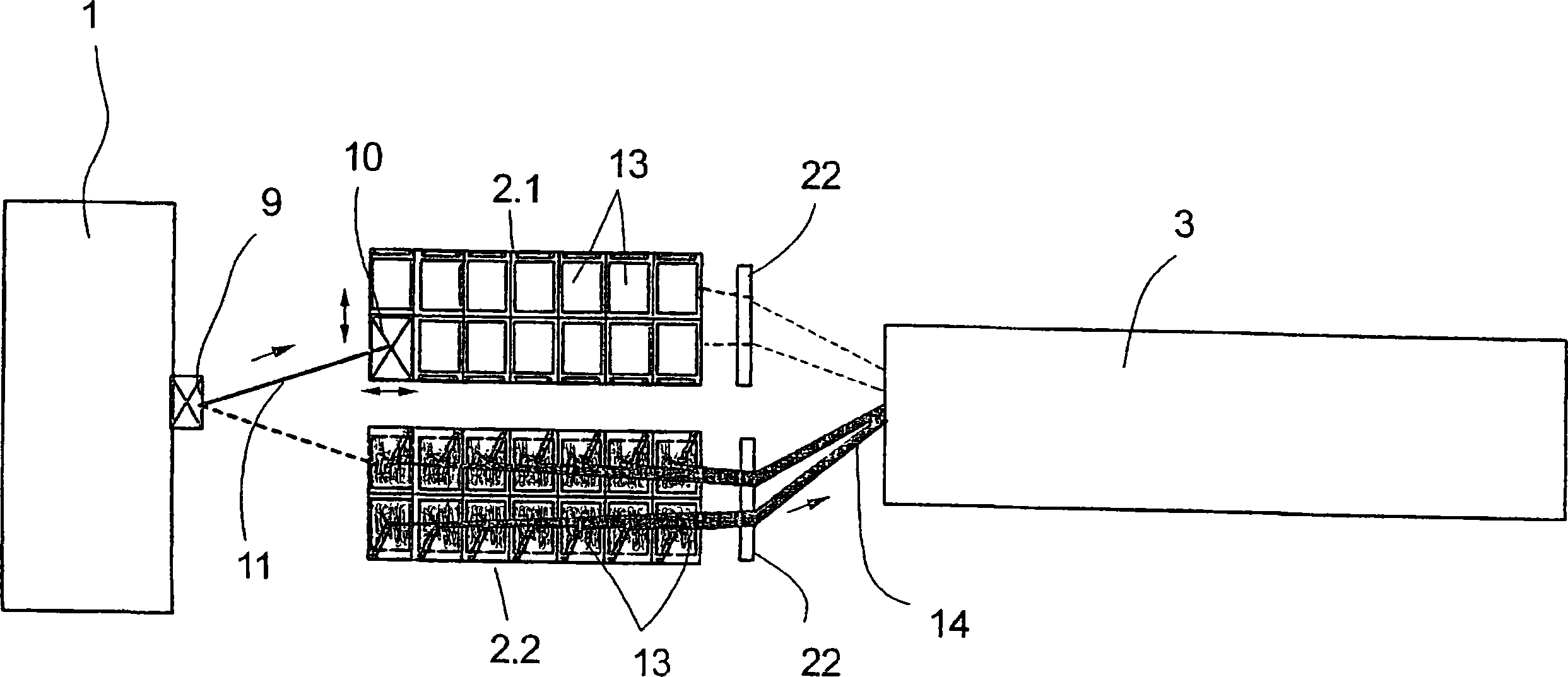

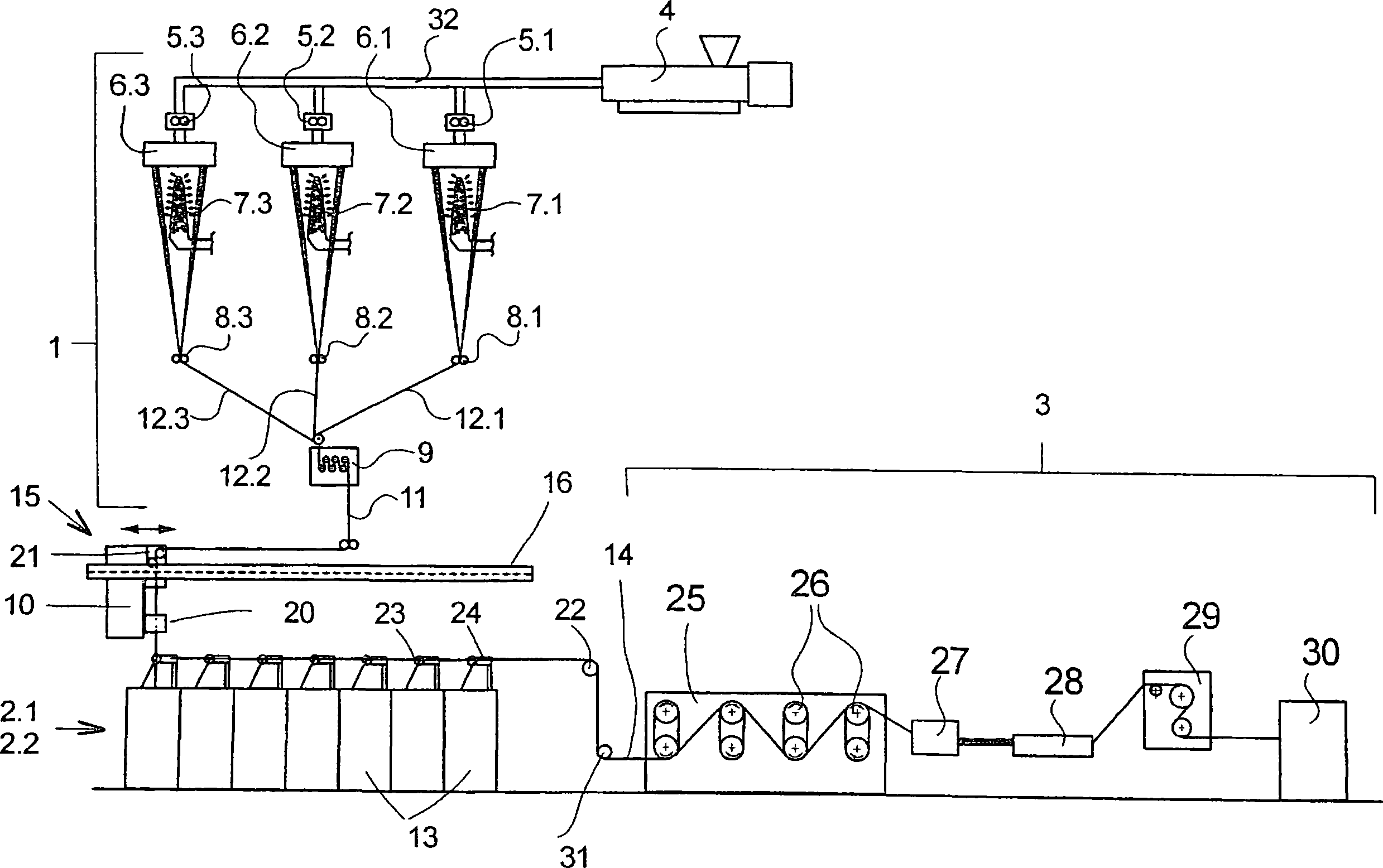

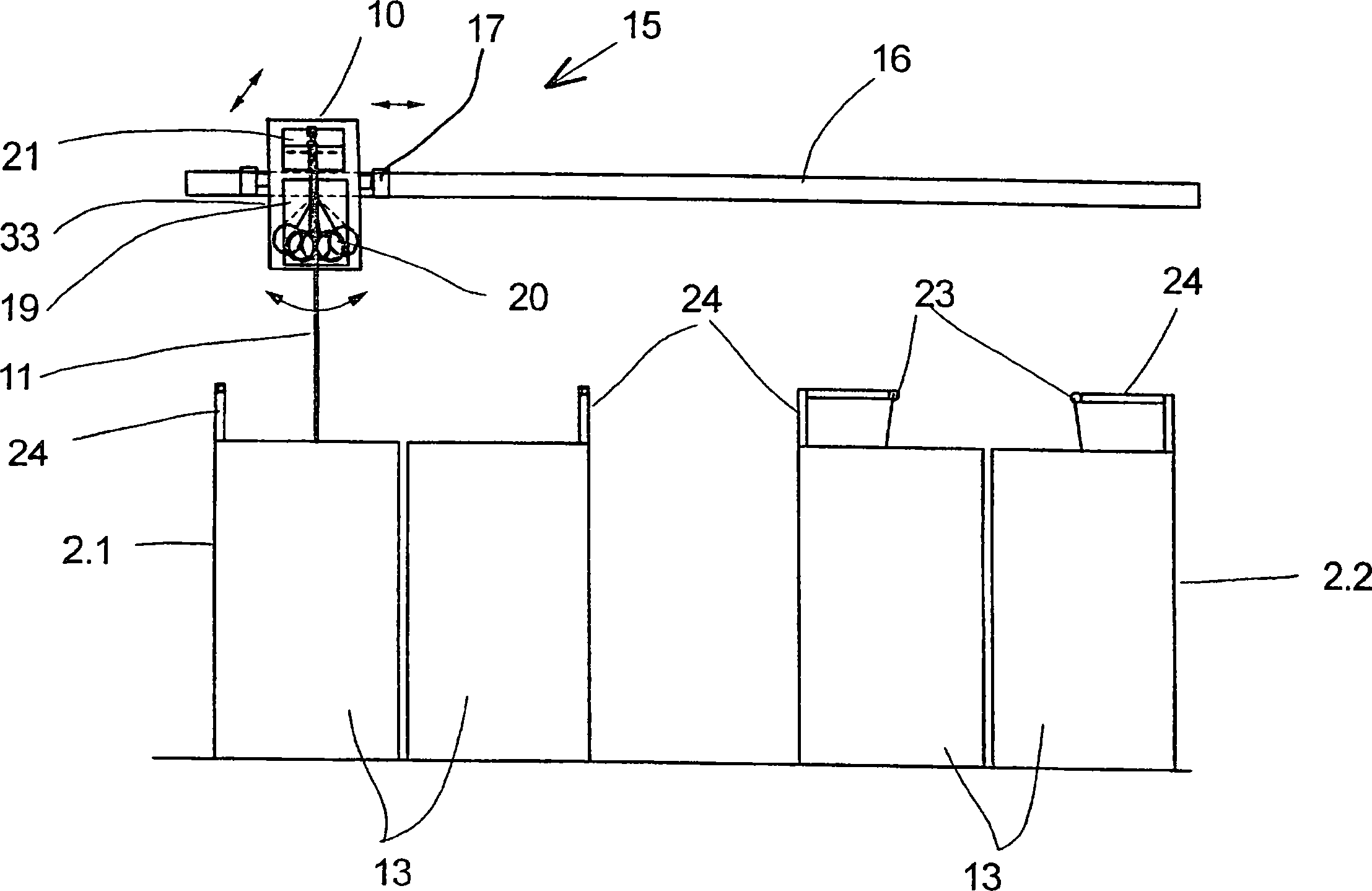

[0023] figure 1 An embodiment of the device according to the invention is shown in top view in . The device comprises a spinning device 1 , two can creels 2 . 1 , 2 . 2 interacting with the spinning device and a treatment device 3 . The spinning device 1 includes a plurality of spinning stations for melt-spinning a plurality of monofilament strands, and the monofilament strands are combined into a tow 11 by a drawing mechanism 9 . The tow 11 reaches the laying device 10 which is guided in a positionable manner above the can creels 2.1 and 2.2 via the draw-off mechanism 9 . The can creels 2 . 1 and 2 . 2 comprise a plurality of cans 13 . exist figure 1 In the arrangement shown, the depositing device 10 is assigned to the can creel 2.1, in which case the first can 13 of the can creel 2.1 is filled. The laying device 10 can be guided to each can of the can creel 2.1 so that the cans 13 of the can creel 2.1 can be filled sequentially with tow.

[0024] The cans 13 held in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com