Color filtering device and fabricating method

A manufacturing method and a color filter layer technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of friction roller damage, alignment material layer damage, alignment material layer damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

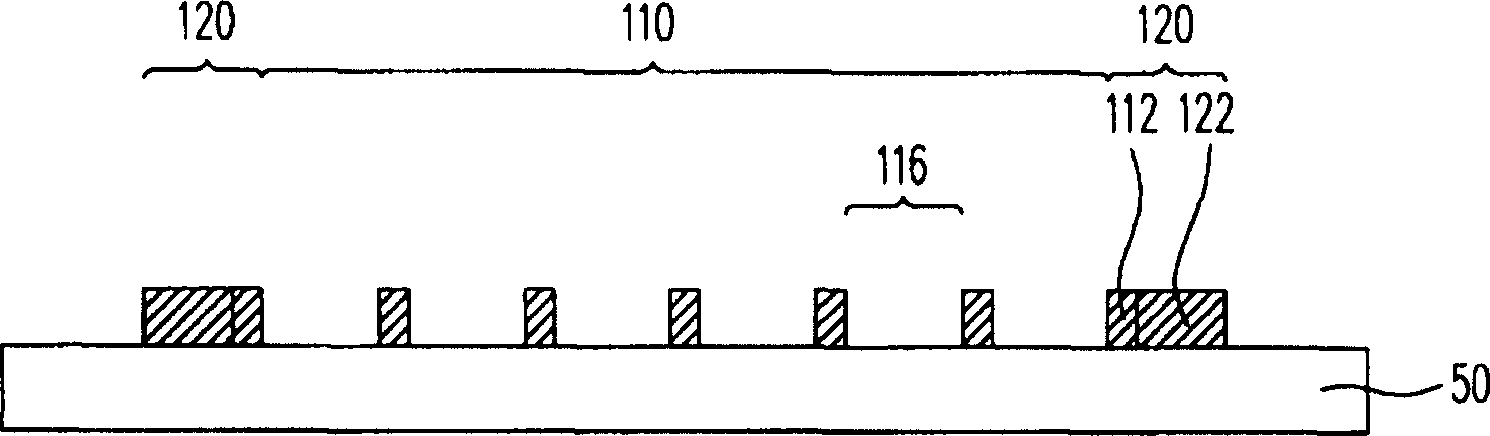

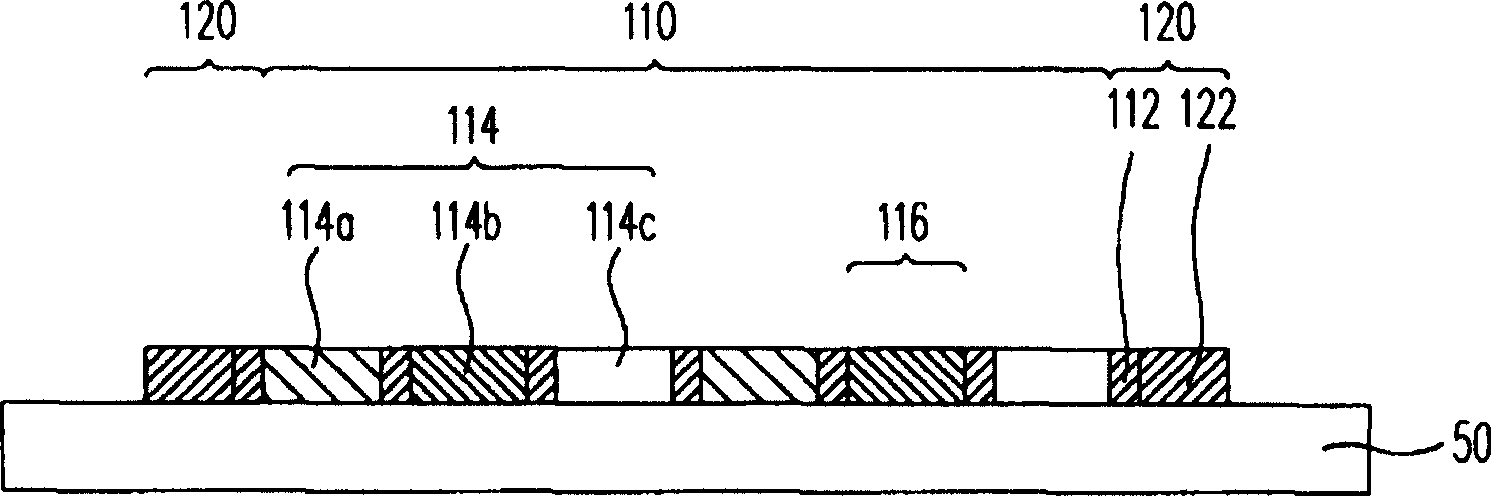

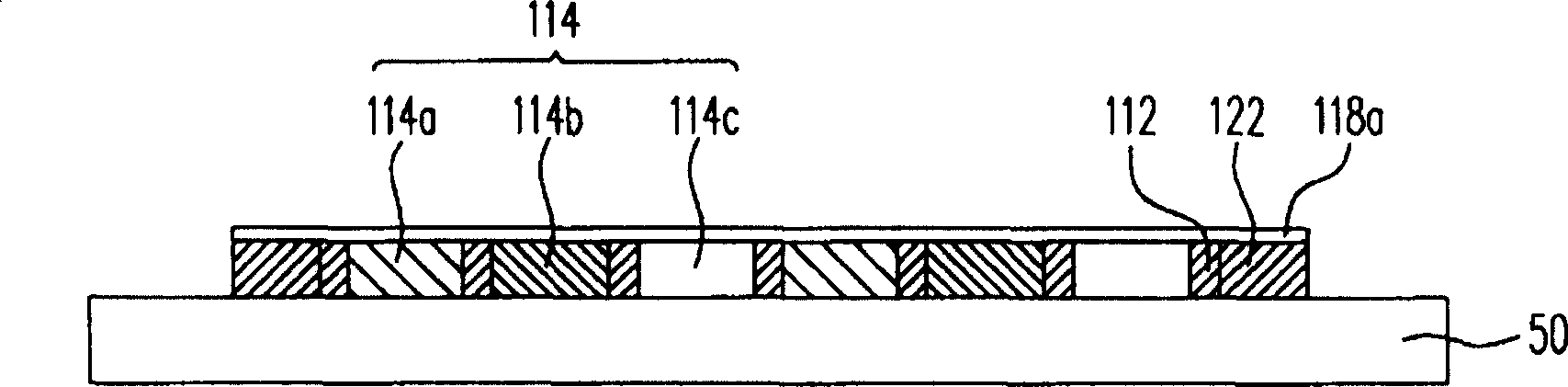

[0051] Figure 2A to Figure 2F It is a schematic cross-sectional view of a manufacturing method of a color filter substrate according to a preferred embodiment of the present invention. Please refer to Figure 2A Firstly, a transparent substrate 50 is provided, which has a display area 210 , a peripheral area 220 and a buffer area 230 , and the peripheral area 220 is located around the display area 210 . Next, a light-shielding pattern layer 212 is formed on the peripheral area 220 on the transparent substrate 50 . In one embodiment, the light-shielding pattern layer 212 is further formed in the display area 210, and the light-shielding pattern layer 212 formed in the display area will define a plurality of sub-pixel areas 216 in the display area 210 of the transparent substrate 50, thus The light-shielding pattern layer located in the display area is also called the light-shielding black matrix 226 . The light-shielding pattern layer 212 formed on the peripheral area 220 o...

no. 2 example

[0064] In addition to using the red filter pattern, green filter pattern or blue filter pattern as the material of the buffer pattern, the present invention can also use the same material as the light-shielding pattern layer as the material of the buffer pattern, but the design of the pattern is different from that of the buffer pattern. The first embodiment is different.

[0065] exist Figure 8A to Figure 8E Only the partial light-shielding frame 222 located in the peripheral area and the buffer patterns 224a, 224b, 224c, 224d, 224e located in the buffer zone are shown. And other film layers such as the color filter layer, light-shielding pattern layer, electrode layer, alignment material layer in the display area are the same as the above-mentioned first embodiment (such as image 3 shown), so it will not be repeated here.

[0066] Please refer to Figure 8A , in this embodiment, the buffer pattern is composed of a plurality of patterns 224a arranged on the edge of the l...

no. 3 example

[0071] The cushioning pattern of the present invention can utilize transparent resin (that is, the material of the spacer) as a cushioning in addition to the red filter pattern, the green filter pattern, the blue filter pattern, and the light-shielding pattern layer as the buffering pattern material. The texture of the pattern. In particular, in this embodiment, the buffer pattern is composed of a plurality of patterns, and the arrangement density of these patterns gradually decreases from the light-shielding pattern layer to the place away from the light-shielding pattern layer.

[0072] exist Figure 9A to Figure 9C Only the partial light-shielding frame 222 located in the peripheral area and the buffer patterns 224f, 224g, 224g' located in the buffer zone are shown in FIG. And other film layers such as the color filter layer, light-shielding pattern layer, electrode layer, alignment material layer in the display area are the same as the above-mentioned first embodiment (such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com