Sealed type compressor

A compressor and sealed technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of reduced production efficiency, loss of piston sliding surface, difficulty in maintaining the accuracy of the sphere, etc., to achieve improved Efficiency and sliding loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

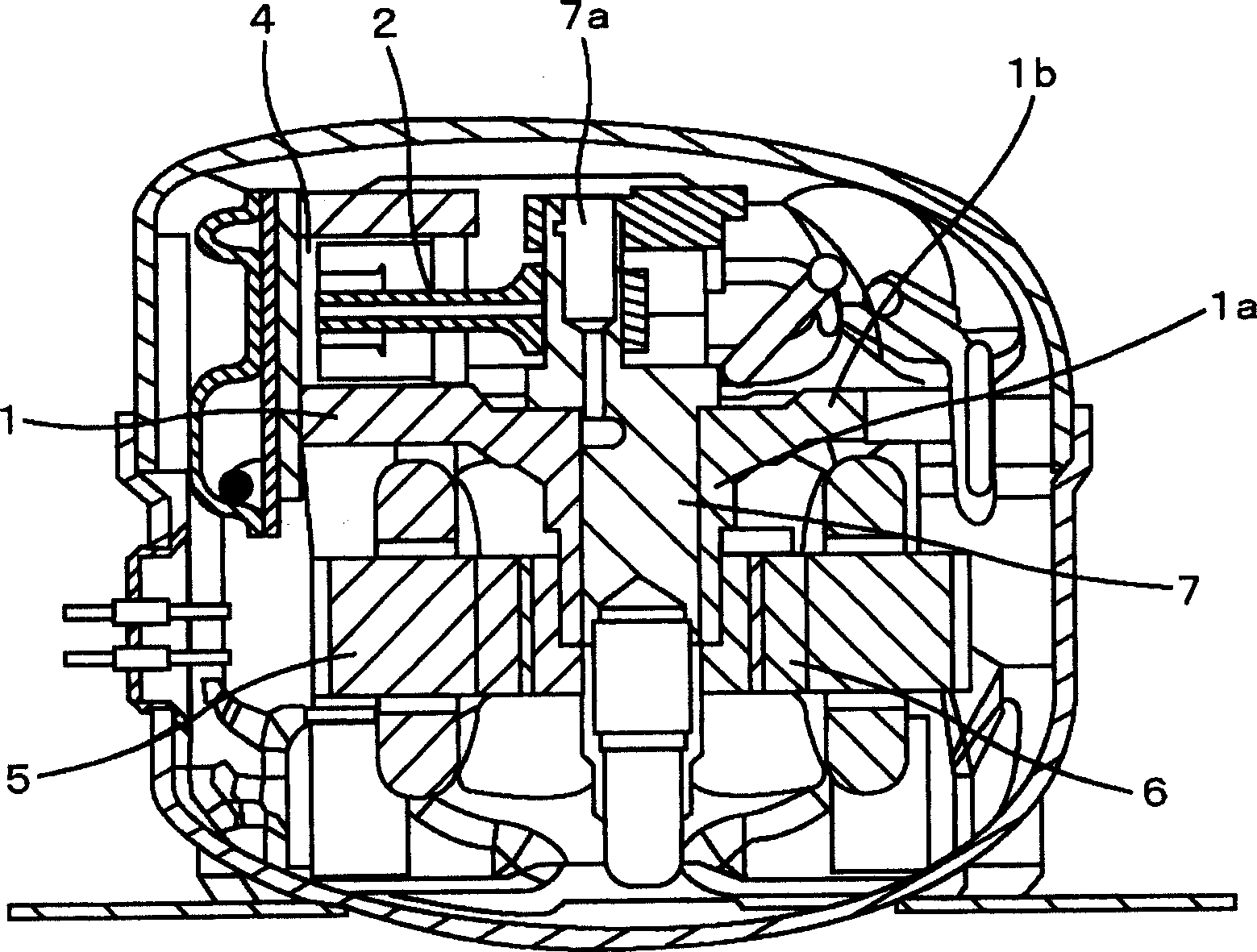

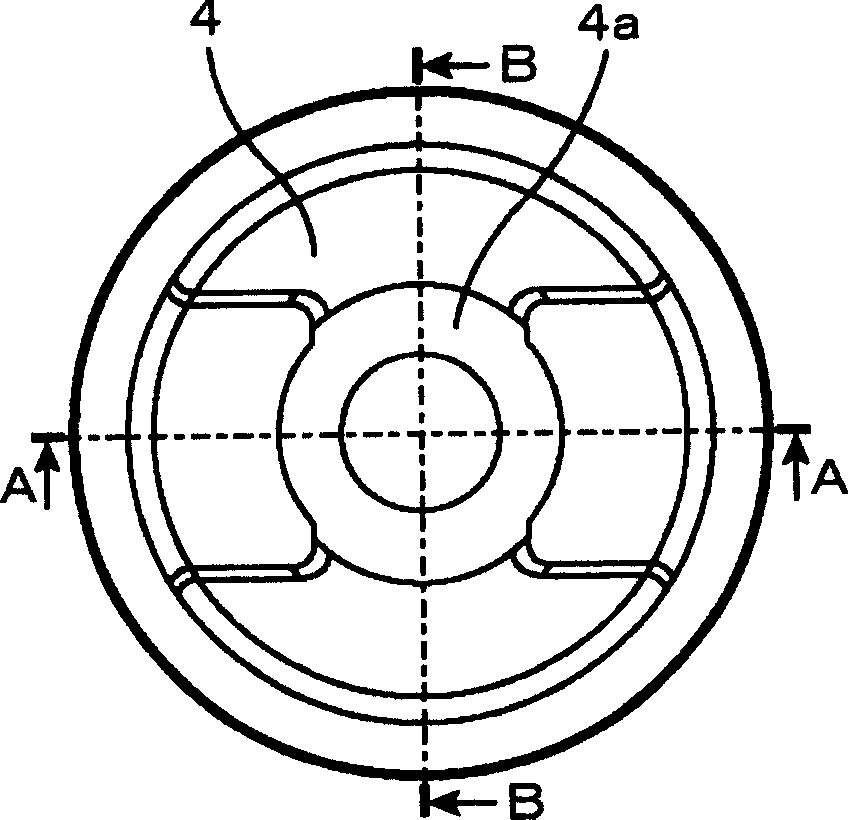

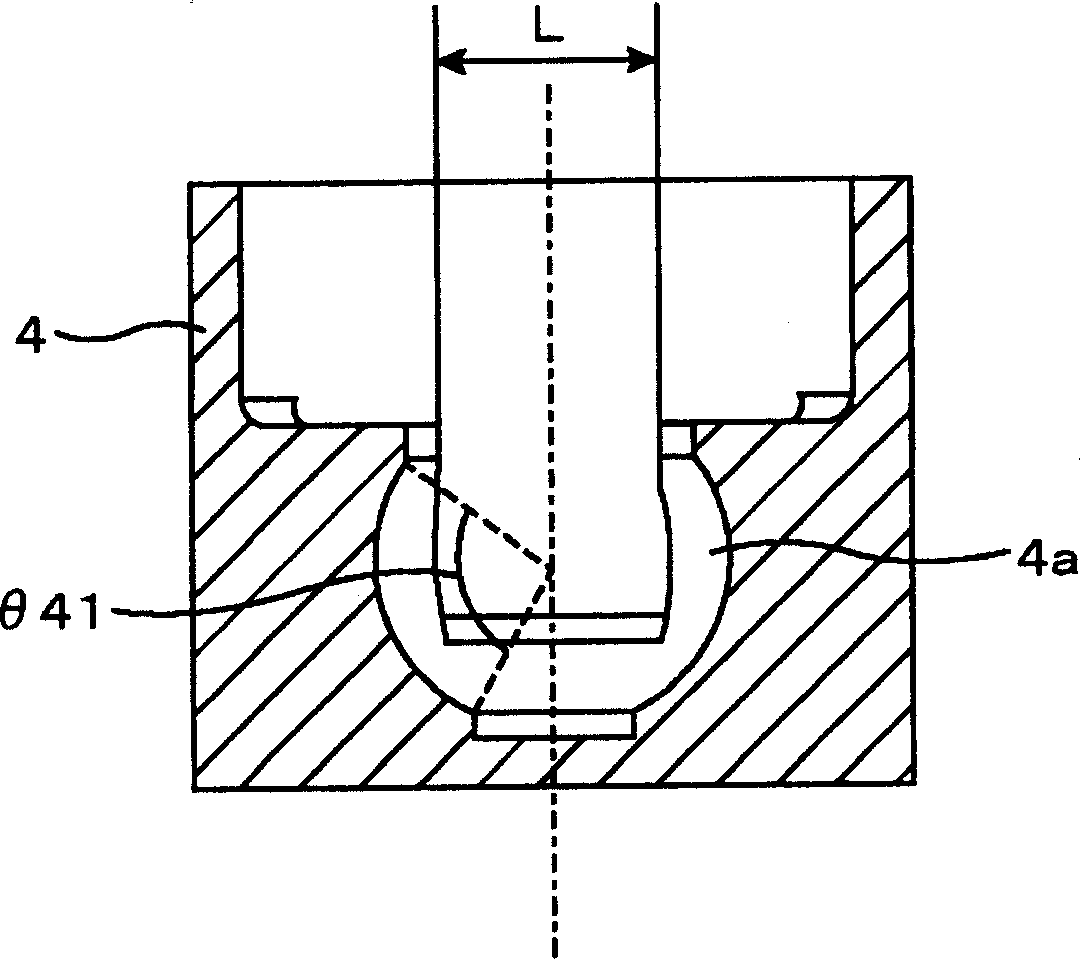

[0054] figure 1 It is a vertical cross-sectional view of a hermetic compressor according to an embodiment of the present invention. The hermetic compressor of this embodiment is a reciprocating compressor. The piston 4 reciprocates in the cylinder 1 to form a compression mechanism. The cylinder 1 is integrally formed by the bearing part 1a and the frame 1b disposed in the airtight container. The lower part of the frame 1b is provided with a stator 5 and a rotor 6 constituting a motor as a motor, and a crank pin 7a is provided at a position eccentric from the rotation center of the crankshaft 7 .

[0055] The crankshaft 7 extends upward from the lower portion of the frame 1b through the bearing portion 1a of the frame, and the crank pin 7a is provided on the upper side of the frame 1b. The lower part of the crankshaft 7 is directly connected to the rotor 6, and the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com