Diamond shaped cradle in truss type

A truss-type, diamond-shaped technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of long distribution beam length of the suspension mechanism, unreasonable stress on the compression rod, inconvenient walking and moving, etc., and achieve reasonable stress. , Simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

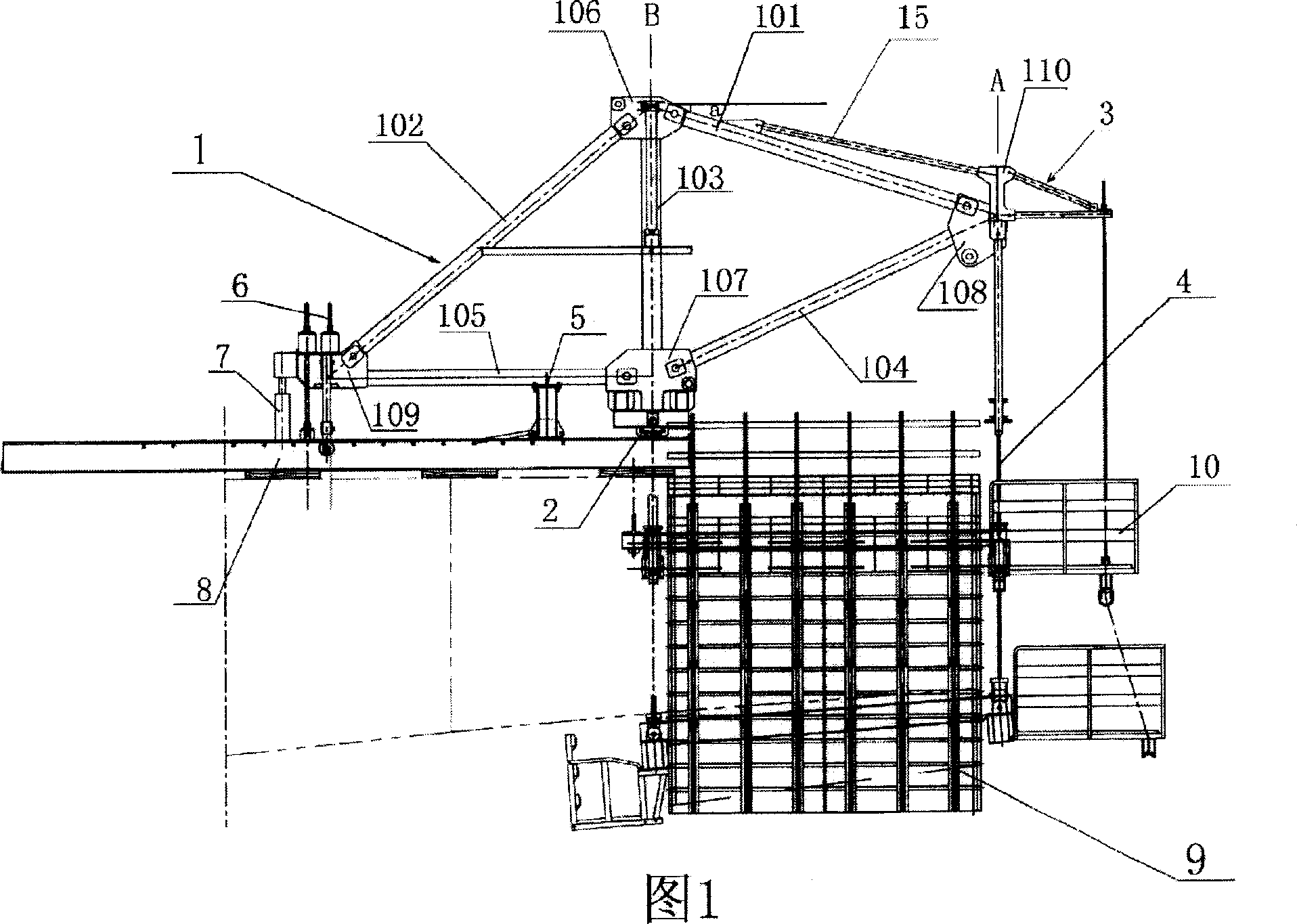

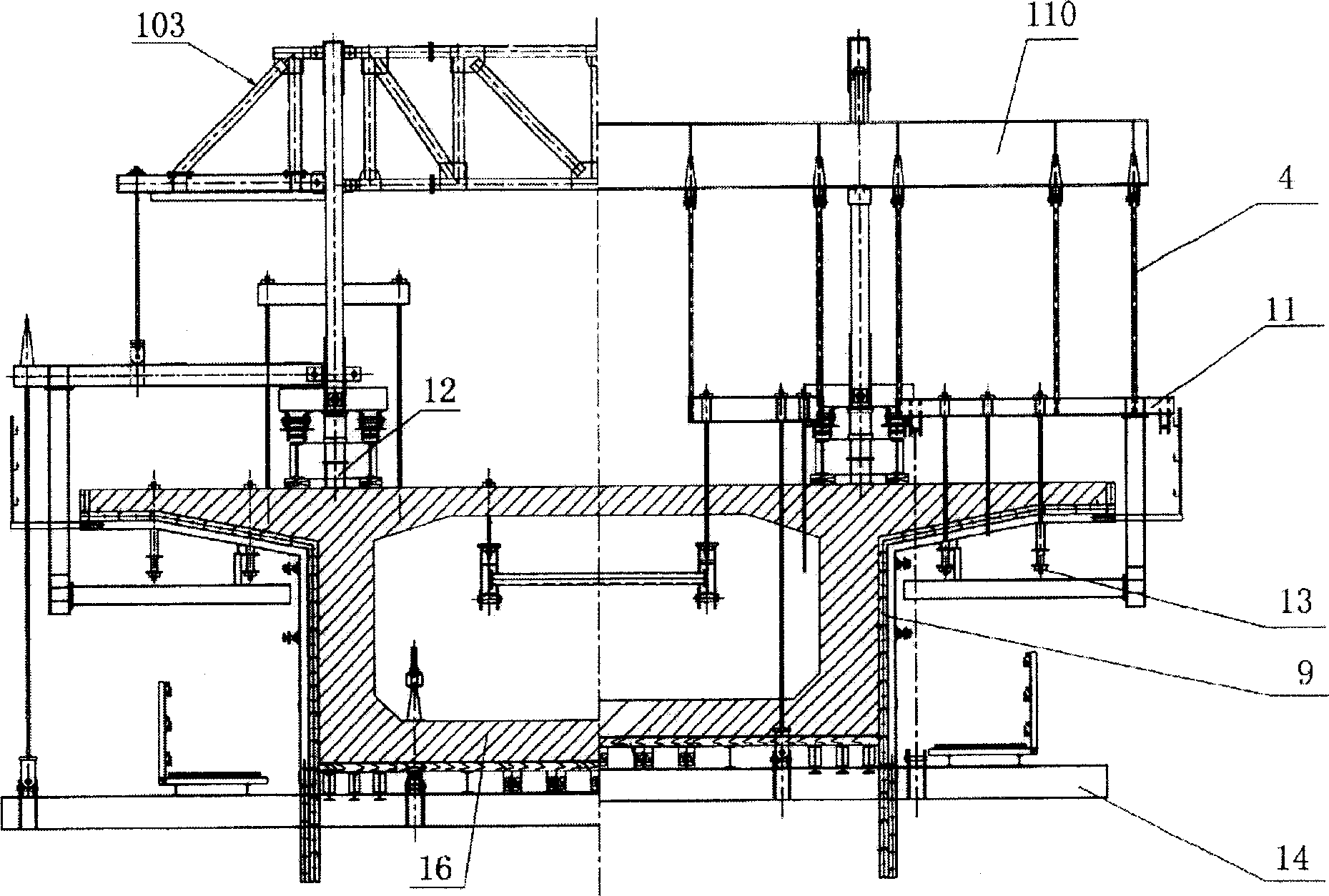

[0017] Referring to Figures 1 and 2 for the embodiment, this diamond-shaped truss-type hanging basket mainly includes a diamond-shaped main truss 1, a running mechanism 22 at the bottom of the main truss, an anchoring device 6 at the rear end of the main truss, and a formwork system connected to the main truss through a suspension mechanism. 9. Above-mentioned anchoring device is the lead screw that connects main truss and track.

[0018] Referring to Fig. 1, the rhombus-shaped main truss 1 is connected into a rhombus by an upper frame 101, a lower frame 105, a front frame 104, and a rear frame 102. On the front bearing 108, the upper end of its upper frame 101 and rear frame 102 is fixed on the upper bearing 106, and the rear end of its rear frame 102 and lower frame 105 is fixed on the rear bearing 109, and the front end of its lower frame 105 and The rear end of the front frame 104 is fixed on the lower support 107; the door-shaped rear hanger 103 is connected between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com