Blended yarn between filament of glass fiber and short fibre of Vinyon N, and production method

A technology of glass fiber and production method, which is applied in the direction of yarn, textile and paper making, and can solve the problem that yarn does not have the effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

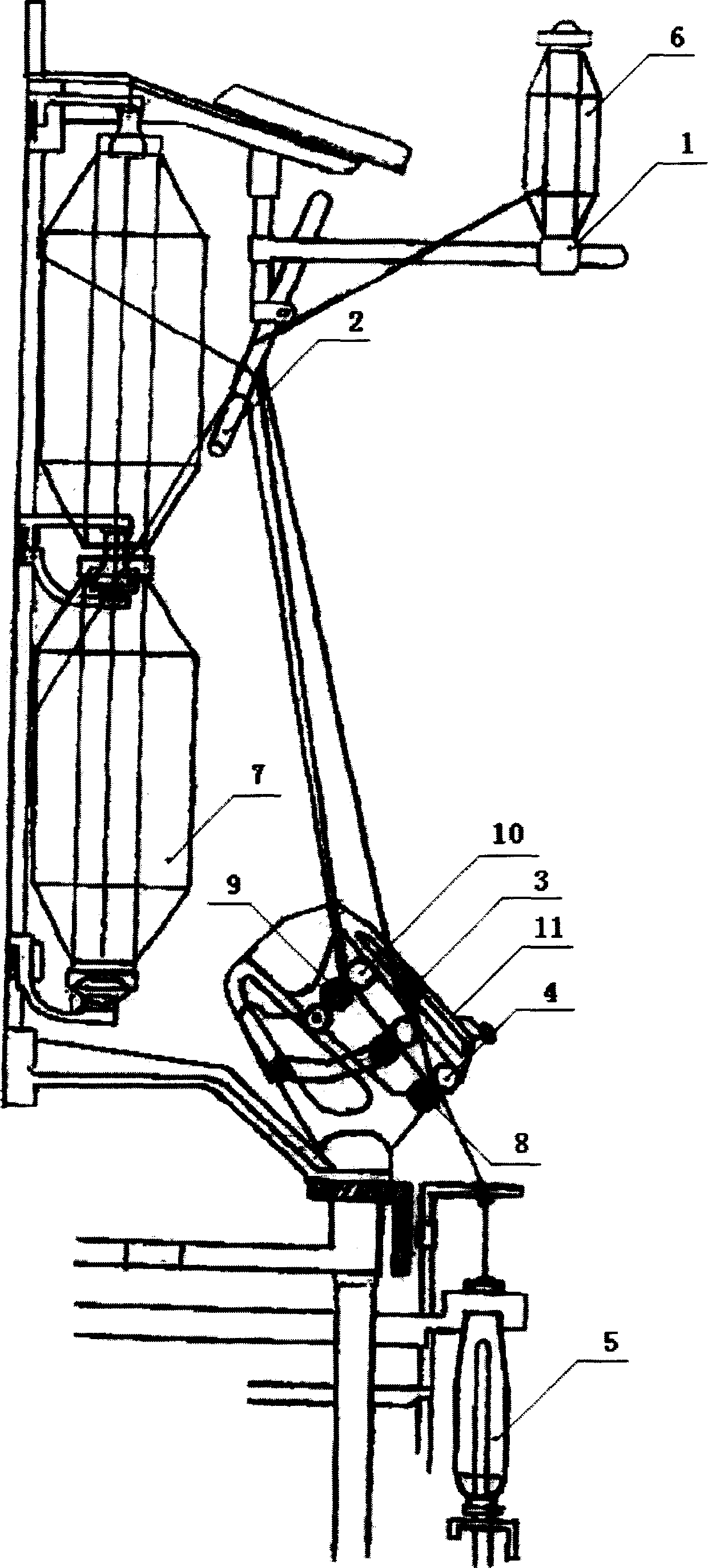

Image

Examples

Embodiment Construction

[0014] A kind of production method of glass fiber long filament and acrylic chloride staple fiber blended yarn, comprises the following steps:

[0015] 1) Pretreatment

[0016] Loosen the packing tape in the middle of the acrylic chloride short fiber steamed bun, tear off the outer packaging, spray evenly on the bun with 5% non-ionic antistatic agent plus aqueous solution, leave it for 24 hours, and set it aside for later use.

[0017] 2) cleaning cotton

[0018] The method of cleaning cotton adopts the method of less beating, more loosening, less grasping and frequent grasping, and a reasonable speed is equipped to improve the operation efficiency of the cleaning equipment, and the operation efficiency is more than 75%.

[0019] 3) Carding

[0020] The carding weight is 16g~25g / 5m; the card clothing of the carding part is made of metal card clothing for chemical fiber, preferably Graff card clothing;

[0021] The distance between each carding part is as follows,

[0022] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com