Bacillus of oxidizing glucose, and application

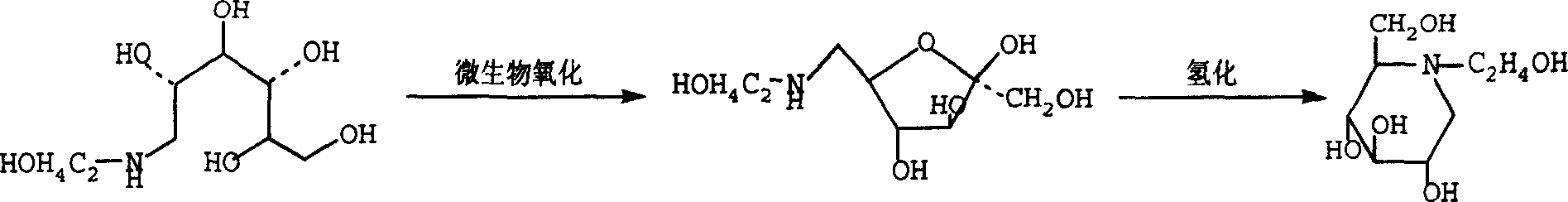

A technology for oxidizing glucose and bacilli, applied in bacteria, fermentation and other directions, can solve the problems of difficult control, difficult separation and purification, and long synthetic route of chemical total synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Natural isolation of strains and NTG mutagenesis treatment

[0027] culture medium

[0028] Slant / Plate Medium: Glucose 10.0%, Yeast Extract 1.0%, CaCO 3 2.0%, agar 2.4%, pH6.8. This medium is used for the cultivation of starting strains, the natural isolation of strains, and the routine passage of strains.

[0029] natural separation

[0030] Take a fresh slant of the strain and add a small amount of sterile water, gently scrape off the bacterial lawn and pour it into a triangular bottle filled with sterile glass beads and sterile water, shake it fully for 10 minutes, and use a sterile sterile cotton bag filled with absorbent cotton. Filter through a funnel to obtain a bacterial suspension. The bacterial suspension was serially diluted and spread on the plate medium, and cultured at 28°C until a single colony grew.

[0031] NTG mutagenesis

[0032] Replace the above sterile water with sterilized phosphate buffer solution, according to the above natural separatio...

Embodiment 2

[0035] culture medium

[0036] Incline medium: same as embodiment 1

[0037] Liquid medium: D-sorbitol 4.5%, glucose 2.0%, beef extract 1.5%, yeast powder 1.5%, KH 2 PO 4 2.4%, pH 6.5

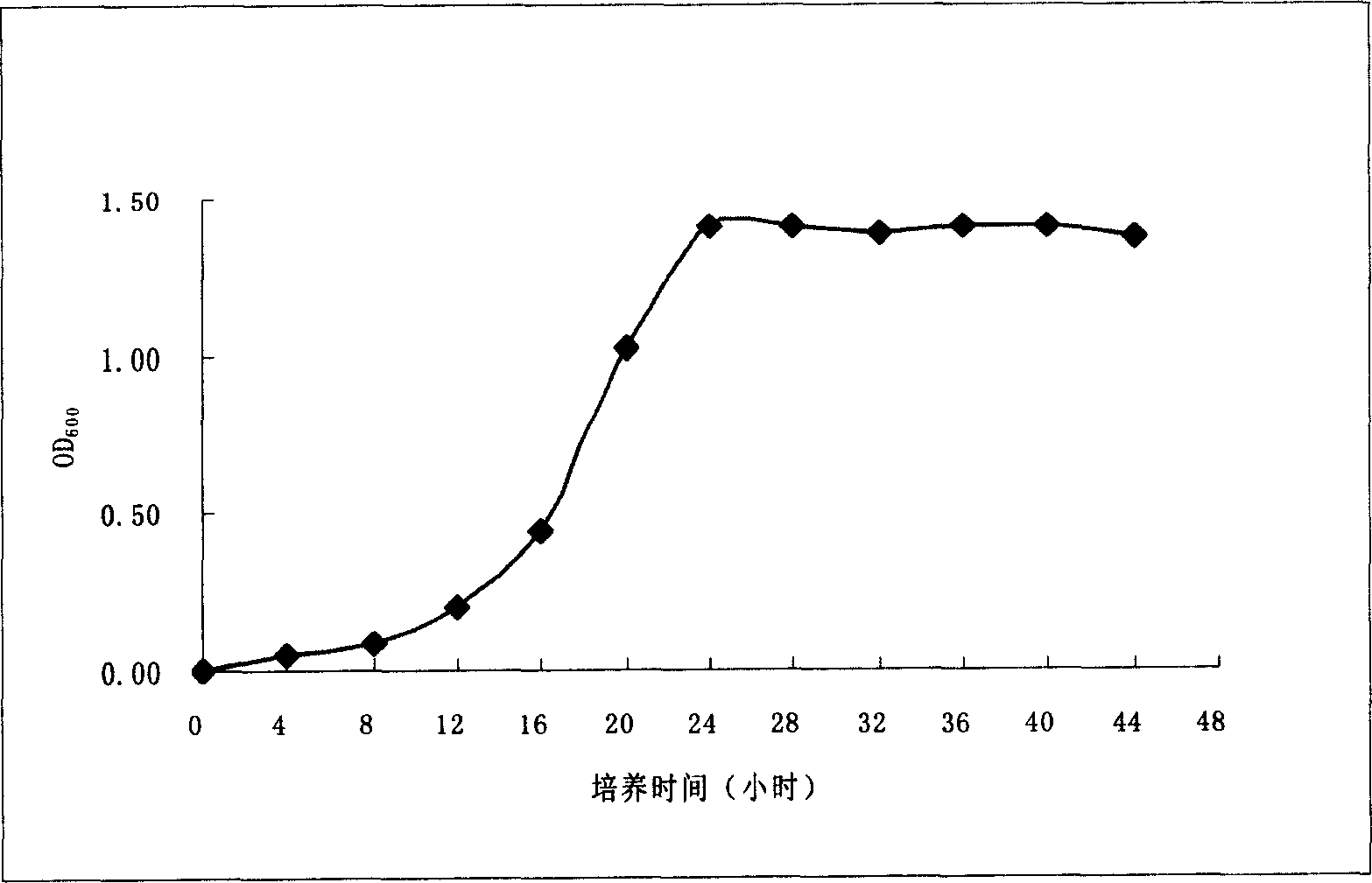

[0038] After the slant of the strain was cultivated at 28°C to mature, the excavated pieces were inoculated into shake flasks containing liquid medium for liquid propagation and culture at 28°C to measure the OD of the culture medium 600 value to reflect the reproductive status of the strain.

Embodiment 3

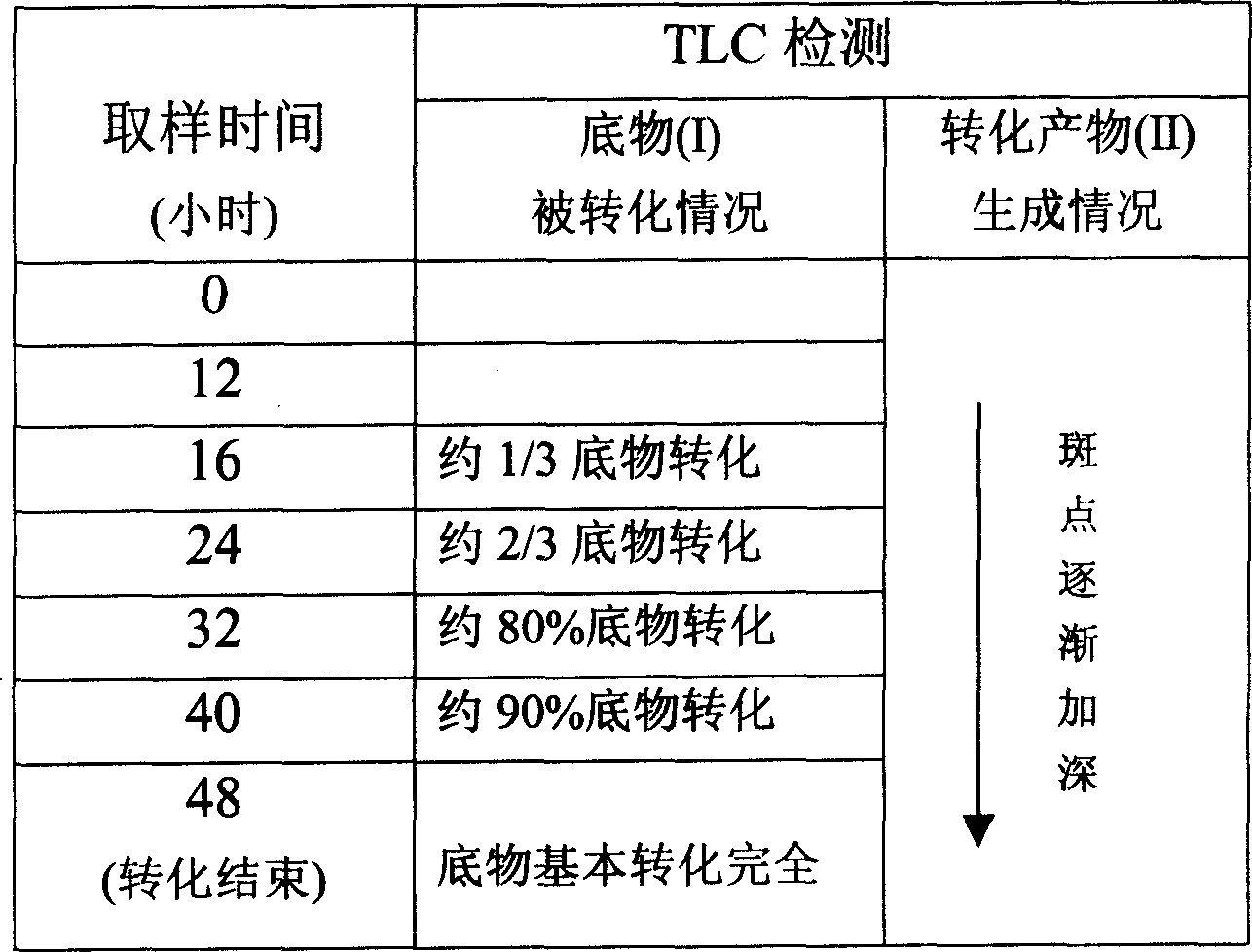

[0040] The bacterium liquid cultivated by the procedure of Example 2 is used as the seed liquid, and is inoculated in a 100L fermenter (cultivation liquid formula in the tank: D-sorbitol 5.0%, glucose 0.5%, yeast extract 2.4%, KH 2 PO 4 3.0%, pH 6.0). The temperature is controlled at 28°C, the ventilation rate is 1:1-1.5, and the stirring speed is 300 rpm. After 24 hours of culture, the cells were collected by centrifugation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com