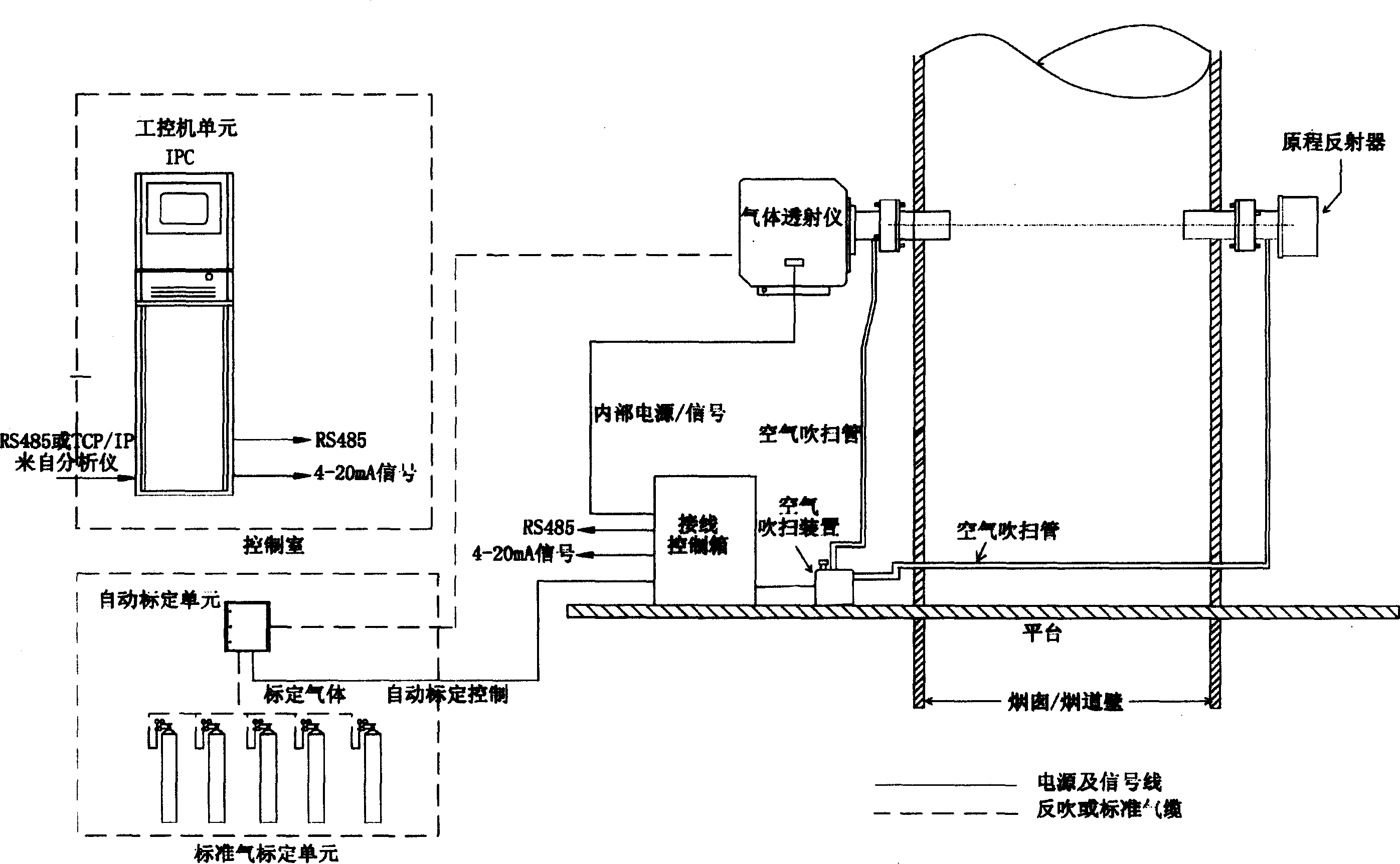

Multi-component infrared online gas analyzer

A gas analyzer, multi-component technology, applied in the direction of analyzing materials, material analysis by optical means, instruments, etc., can solve problems such as real-time control and slow speed in unfavorable industrial sites, and achieve convenient networking and strong corrosion resistance. , the effect of low maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

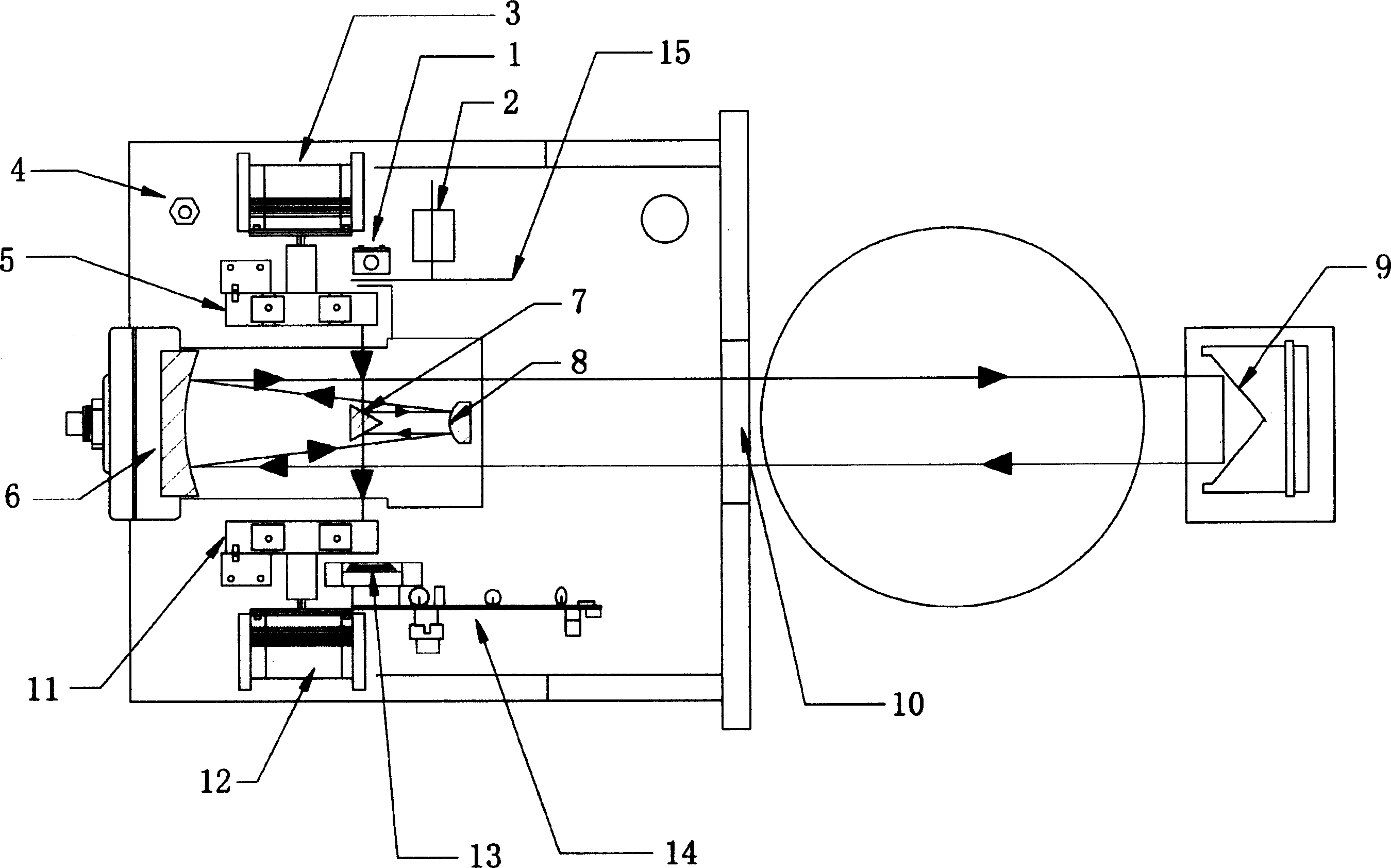

[0039] The infrared rays emitted by the infrared light source 1 enter the self-calibration runner 5 through the chopper wheel 3 driven by the chopper motor 2 . The function of the self-calibration runner 5 is to perform self-calibration once in a certain time interval to determine whether the system works normally. After the infrared ray passes through the self-calibration wheel 5, it hits the corner cube prism 9, and then the beam is reflected on the convex mirror 8, and after being reflected by the convex mirror 8, the beam reaches the concave mirror 6, and the beam reflected by the concave mirror 6 passes through the measuring gas It reaches the corner cube prism 9 and is reflected back to the concave mirror 6. So actually the infrared rays are absorbed twice by the measured gas. Then, the concave mirror 6 reflects the infrared rays back to the convex mirror 8, and the convex mirror 8 reflects the infrared rays to the corner cube prism 9, and reaches the photoelectric sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com