Online rear axle noise quality detecting system

A detection system and quality technology, applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problems that the sound pressure value cannot accurately reflect the real level of rear axle noise, and the impact of the acoustic environment on the measurement accuracy, etc. , to achieve the effects of compact structure, strong anti-interference ability, prevention of leakage and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

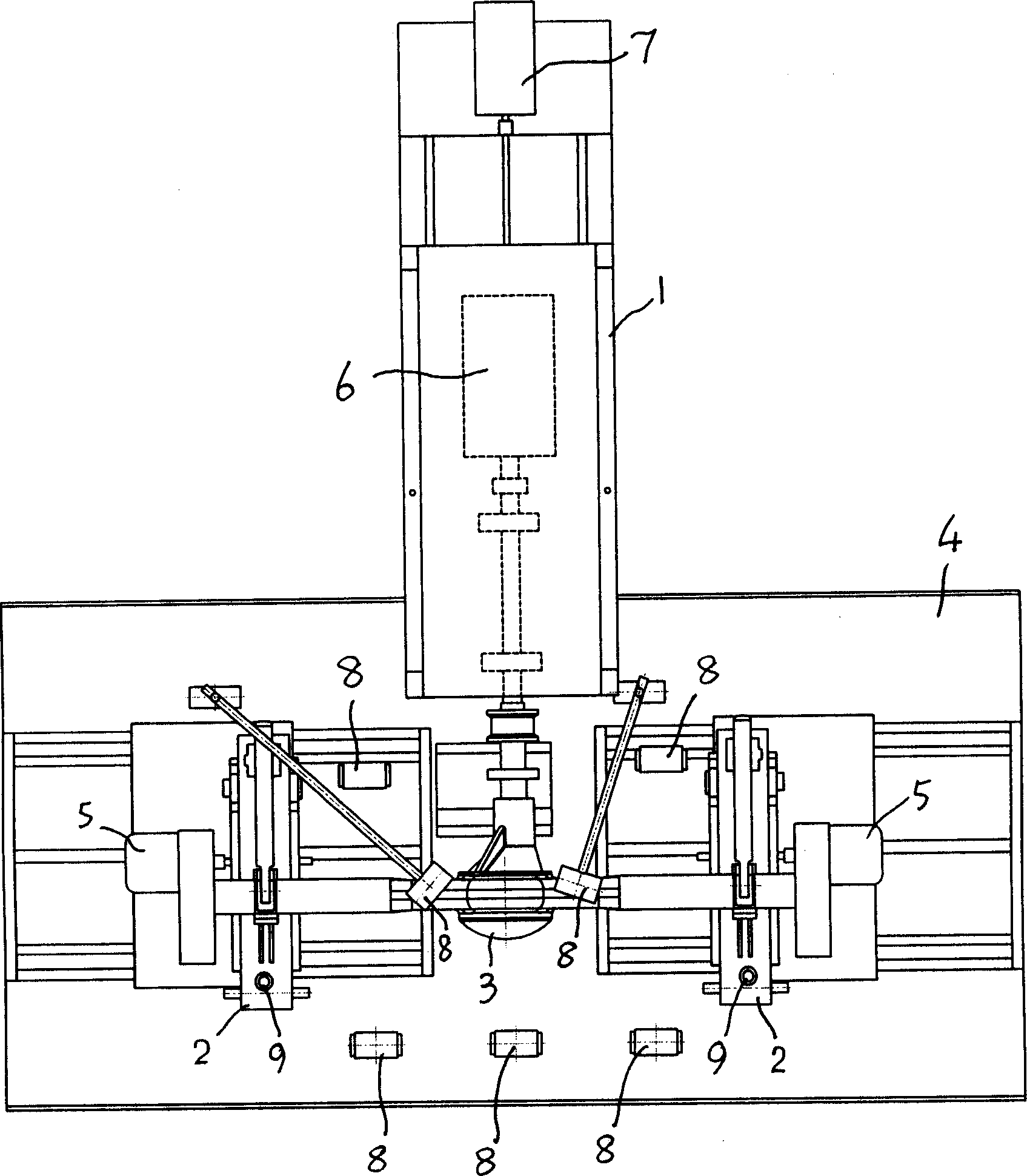

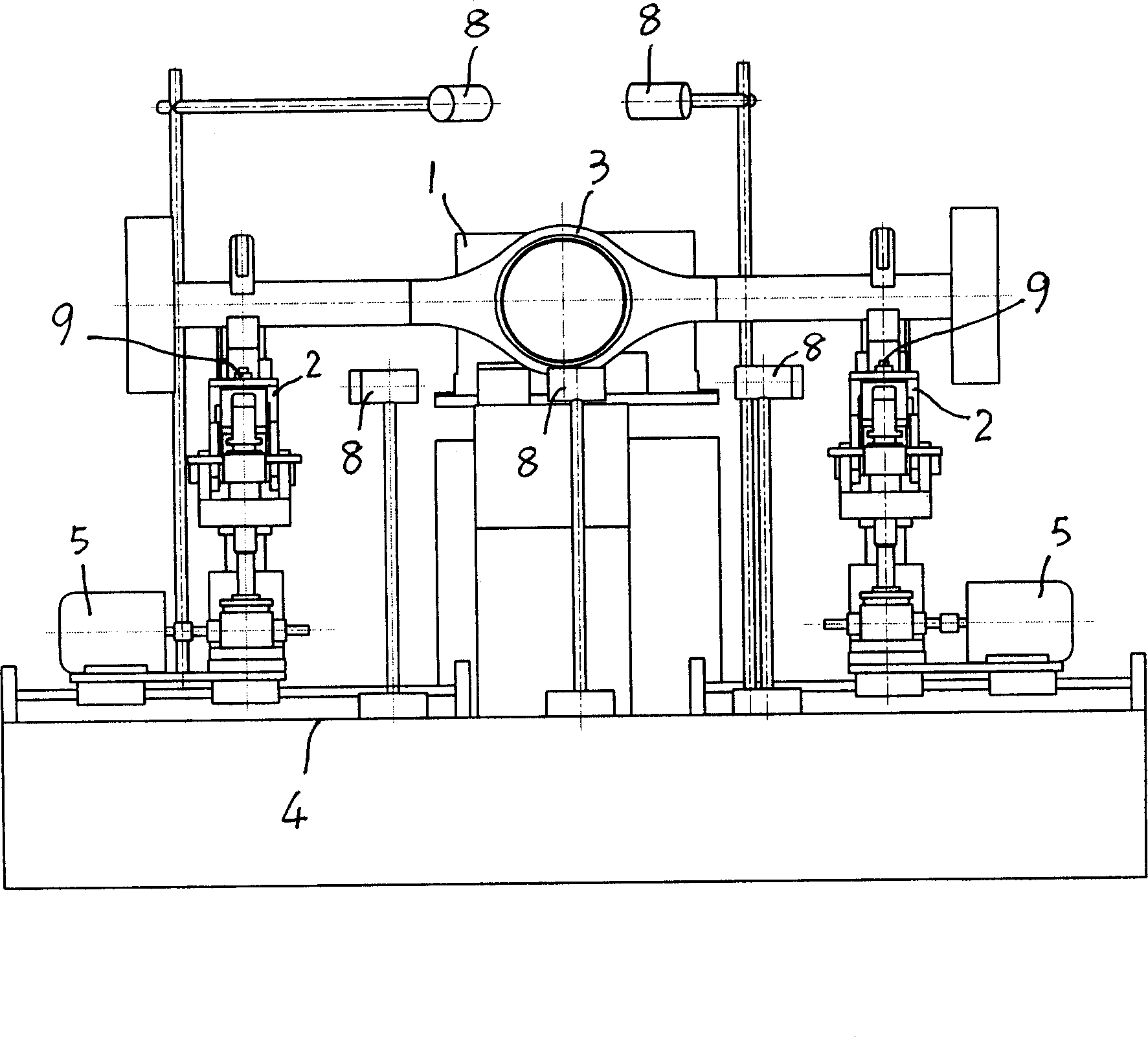

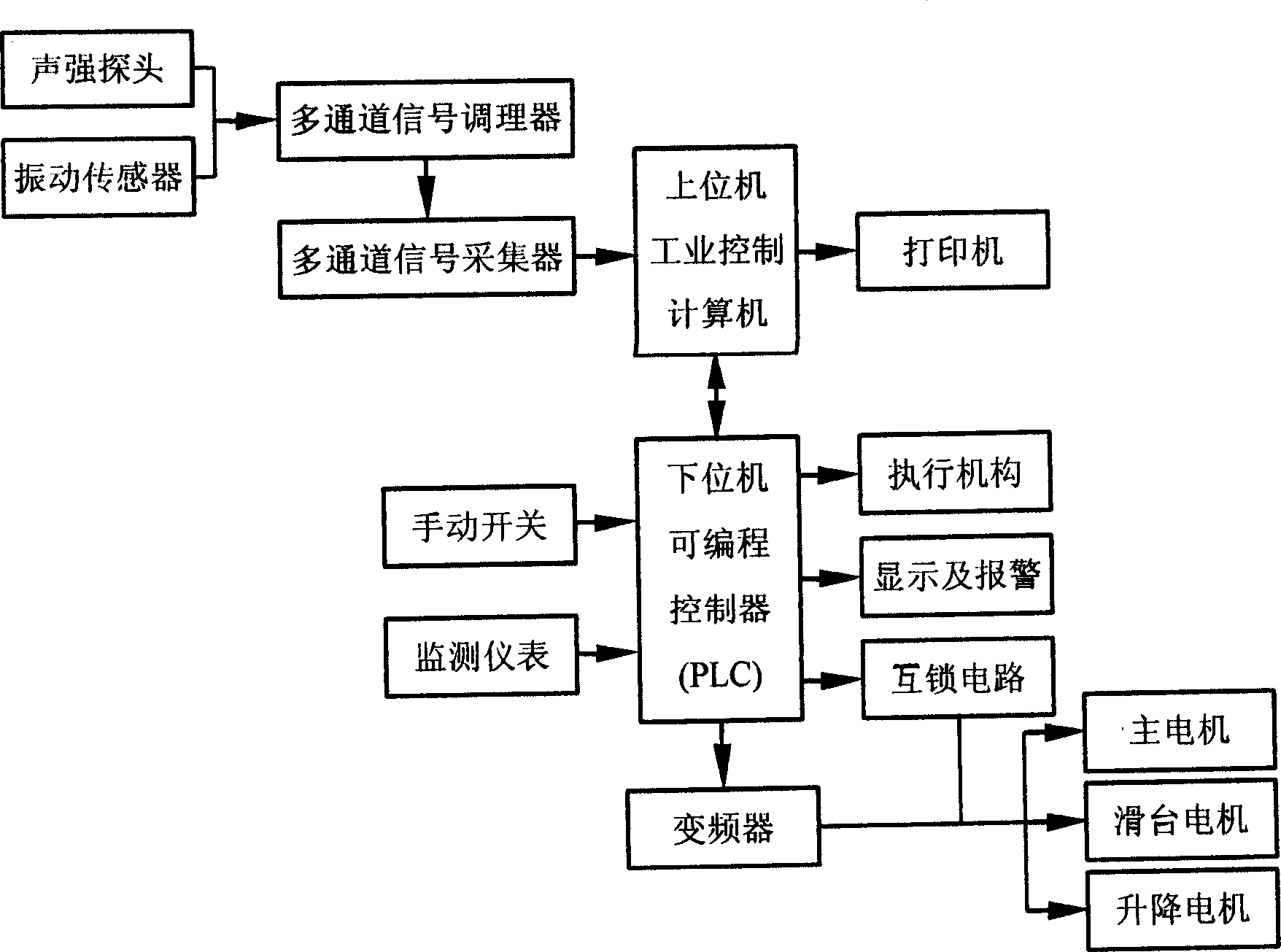

[0023] see figure 1 , figure 2 , in this embodiment, the whole of the test bench is in the shape of a "T", and the front part is a rigid platform 4 that meets the requirements of acoustic reflection. The left and right groups are installed on the rigid platform 4 to adjust the test posture of the rear axle, and are controlled by the lifting motor. 5-driven lifting platform 2, the measured rear axle 3 is supported on the lifting platform 2 on the left and right sides, and the rear axle 3 of the same series does not need to be adjusted after the attitude is adjusted.

[0024] The rear part of the test bench is a power slide 1 driven by a slide motor 7. The main motor 5 that provides driving force for the rear axle 3 under test according to the set speed and steering is set on the power slide 1. The output of the main motor 5 The shaft is connected to the drive shaft of the rear axle 3 under test; the main motor 5 drives the rear axle 3 at speeds of 500r / min, 1100r / min and 2200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com