Gas jetting device, electronic device and gas jetting method

A gas injector and gas injection technology, which are applied in the structural parts of electrical equipment, mechanical equipment, electric solid devices, etc., can solve the problems of drum-shaped circular membrane noise, etc., and achieve the effect of suppressing noise and increasing the amount of gas injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described below with reference to the accompanying drawings.

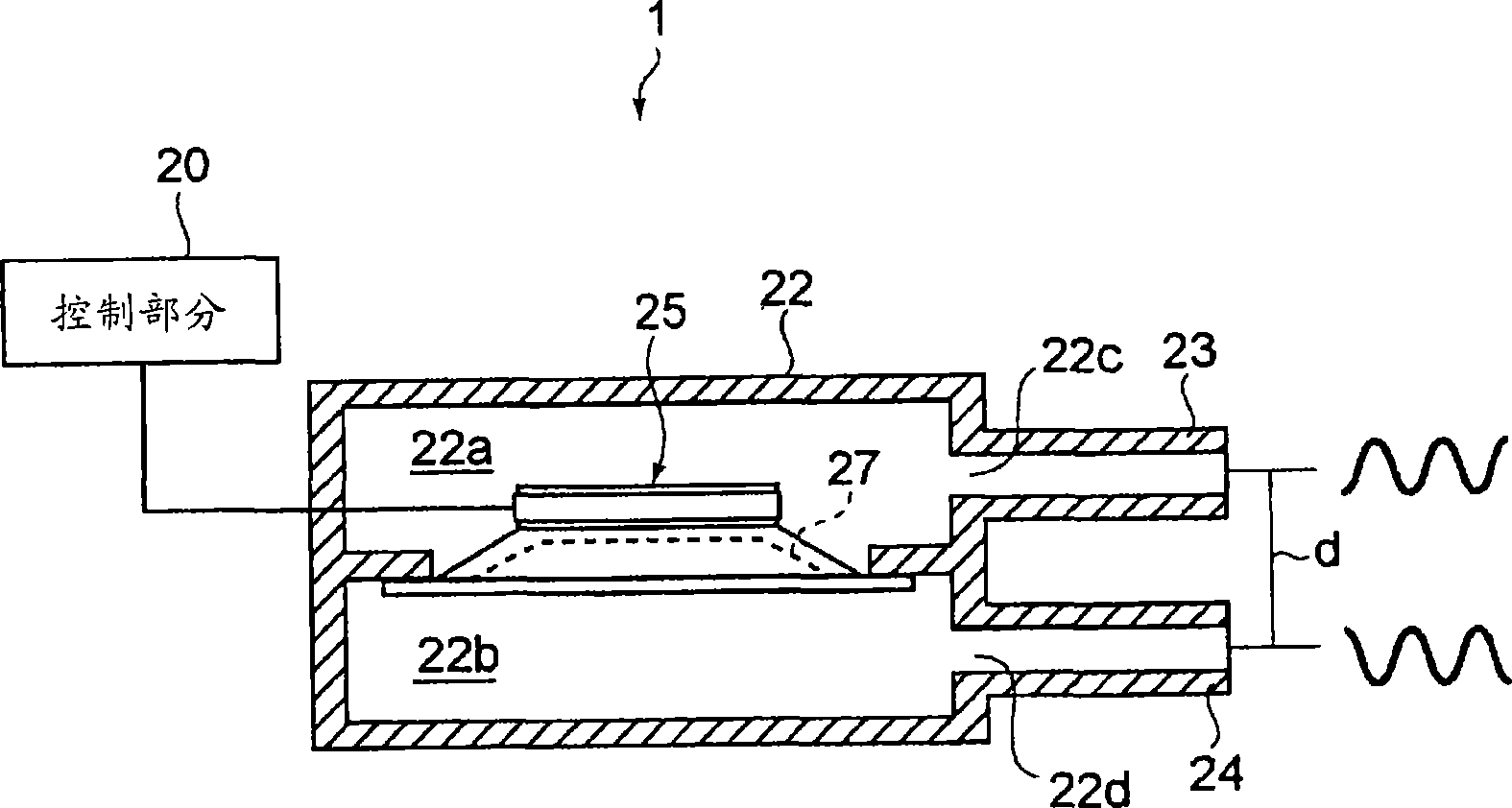

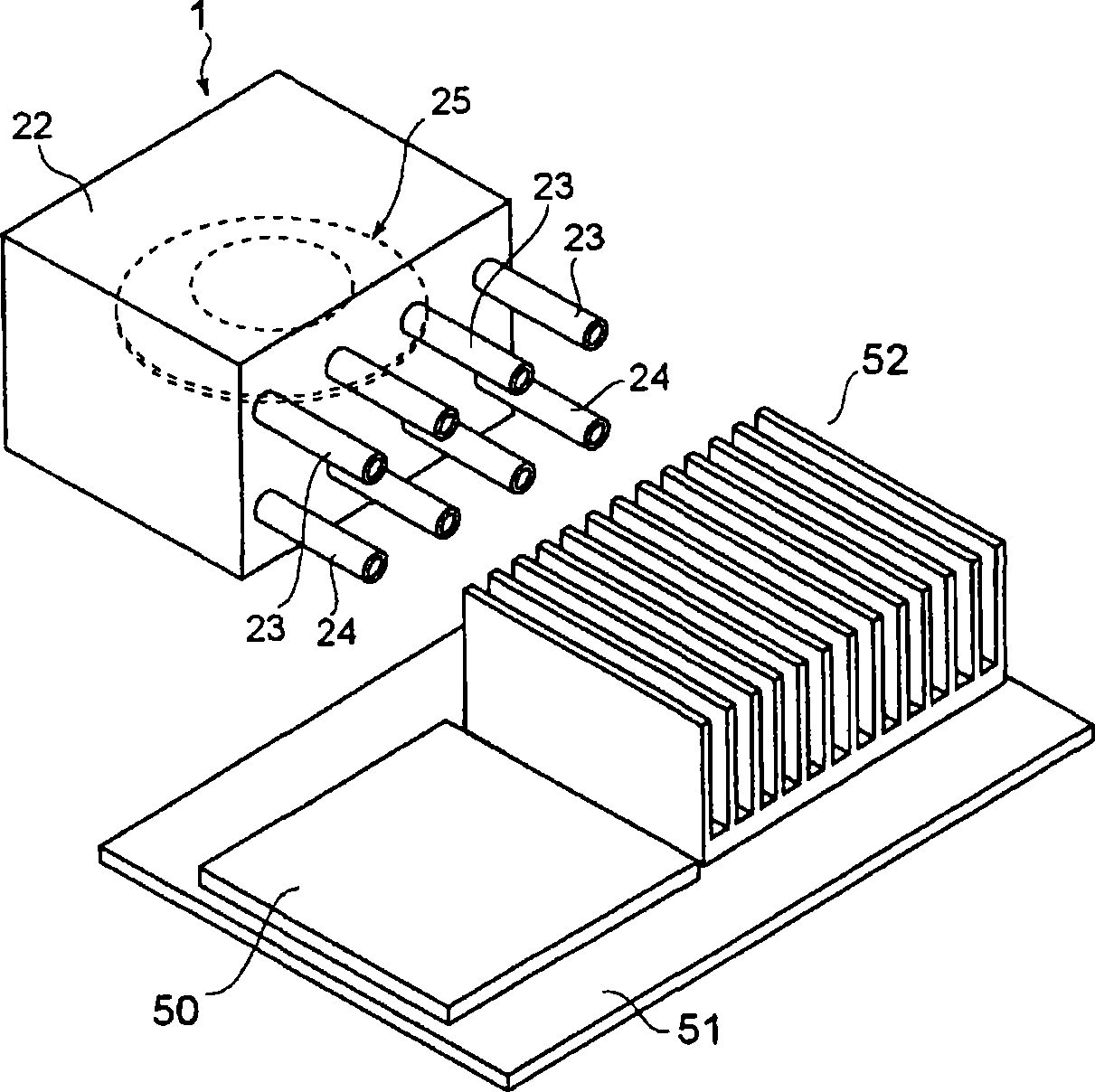

[0052] figure 1 is a perspective view of a gas injector according to one embodiment of the present invention, figure 2 is a cross-sectional cutaway view of the gas injector.

[0053] The gas injector 1 comprises a separate housing 22 . A vibrator 25 is provided in the housing 22, and the inside of the housing 22 is divided into two chambers 22a and 22b by the vibrator 25. As shown in FIG. Chambers 22a and 22b contain, for example, air. A plurality of opening portions 22c and 22d are formed in the housing 22 so as to allow the above-mentioned divided chambers 22a and 22b to communicate with the outside of the housing 22, respectively. In this case, the numbers of the opening portions 22c and 22d are the same as each other. The number of opening portions 22c (22d) may be single. The nozzles 23 and 24 are respectively provided on the opening portions 22c and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com