Sealing ring for centrifugal pump

A sealing ring and centrifugal pump technology, applied in the field of centrifugal pump sealing ring, can solve the problems of uneven flow change of double-suction centrifugal pump, reducing the inlet pressure of impeller, affecting the hydraulic performance of the unit, etc., so as to avoid hydraulic loss, reduce vortex and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

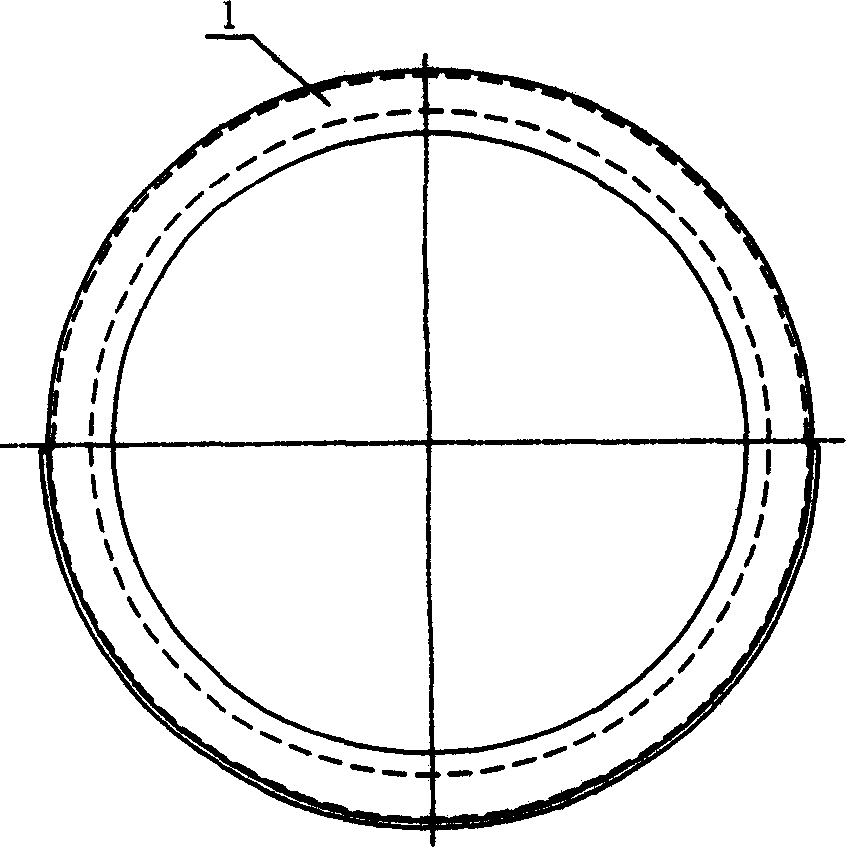

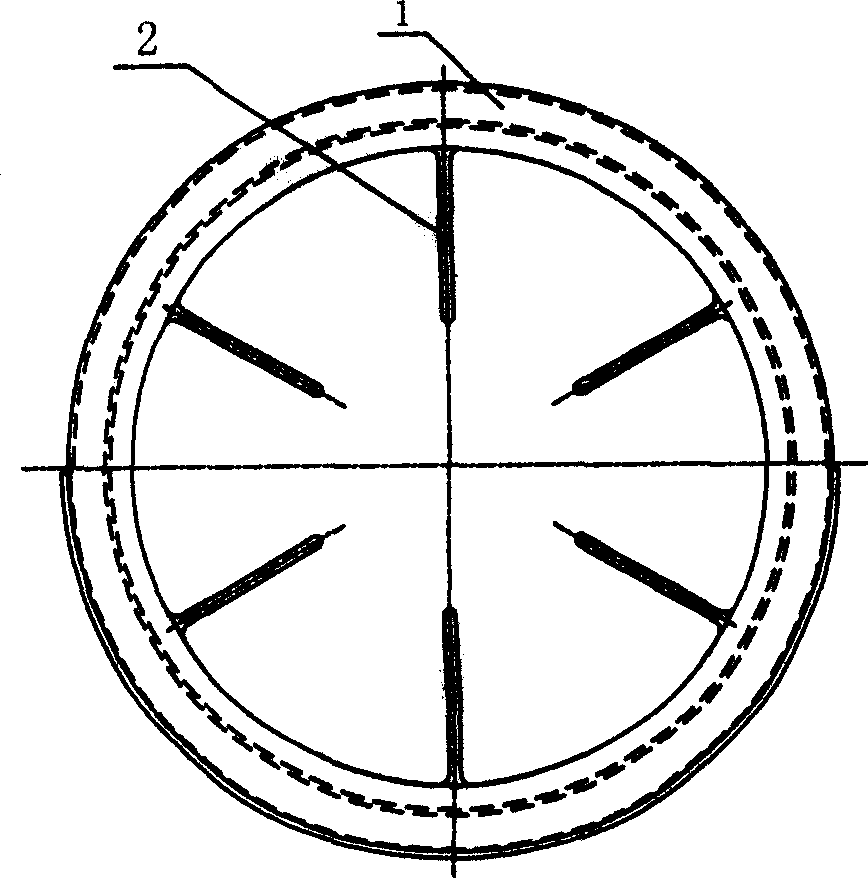

[0012] see image 3 , Figure 4 , on the inner wall 6 of the sealing ring 1, there are n pieces of rectifying grids, the number n of which is: usually 2≤n≤the number of impeller blades, and the rectifying grids at the top of the center line of the sealing ring are evenly distributed on the basis of the rectifying grids On the circumference of the inner wall 6 (note: a large number of rectifying grids will increase the friction loss of the pump under the condition of large flow rate). The width, thickness, length and transition radius of its rectifying grid sheet 2 can be determined according to specific conditions.

[0013] see Figure 5 , is a schematic diagram of the joint use of the seal ring and the impeller of the present invention, and a labyrinth seal groove 4 is provided at the straight opening of the joint portion of the seal ring 1 and the impeller 5 . This technique is relatively clear to those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com