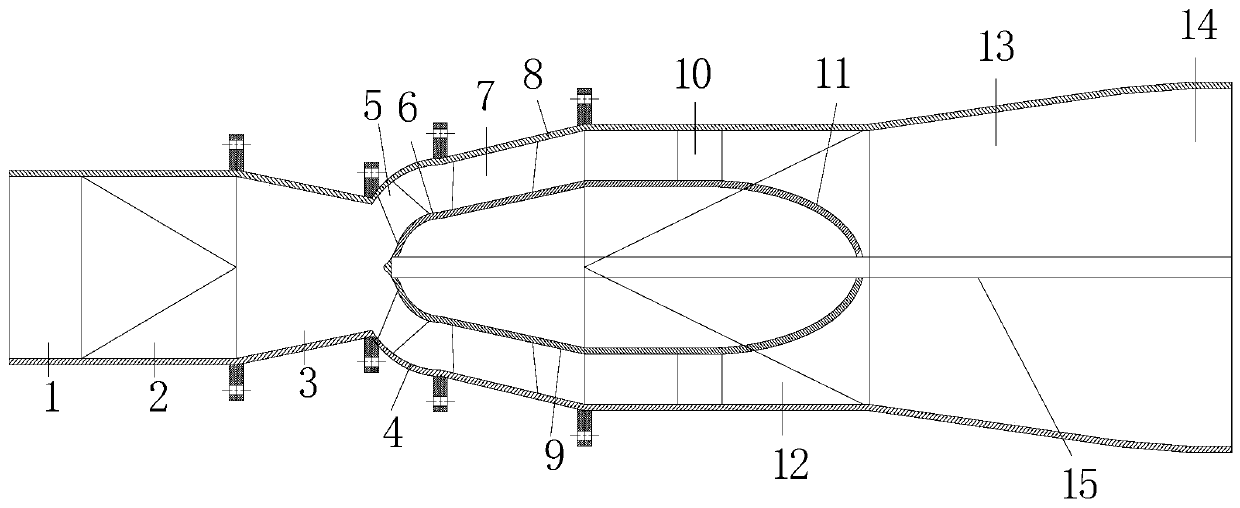

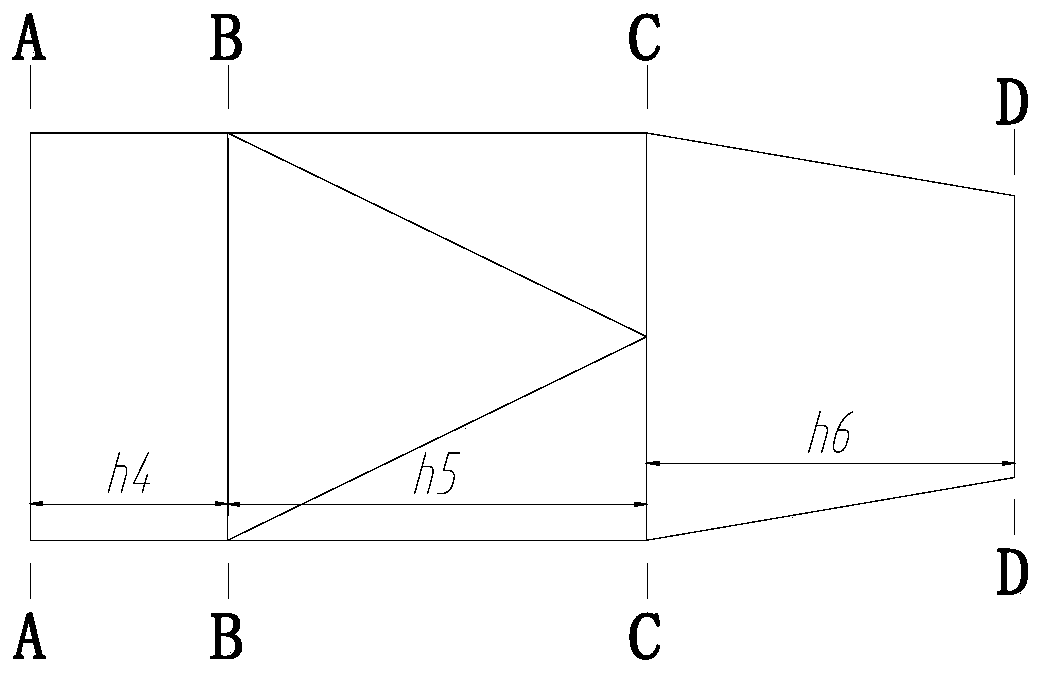

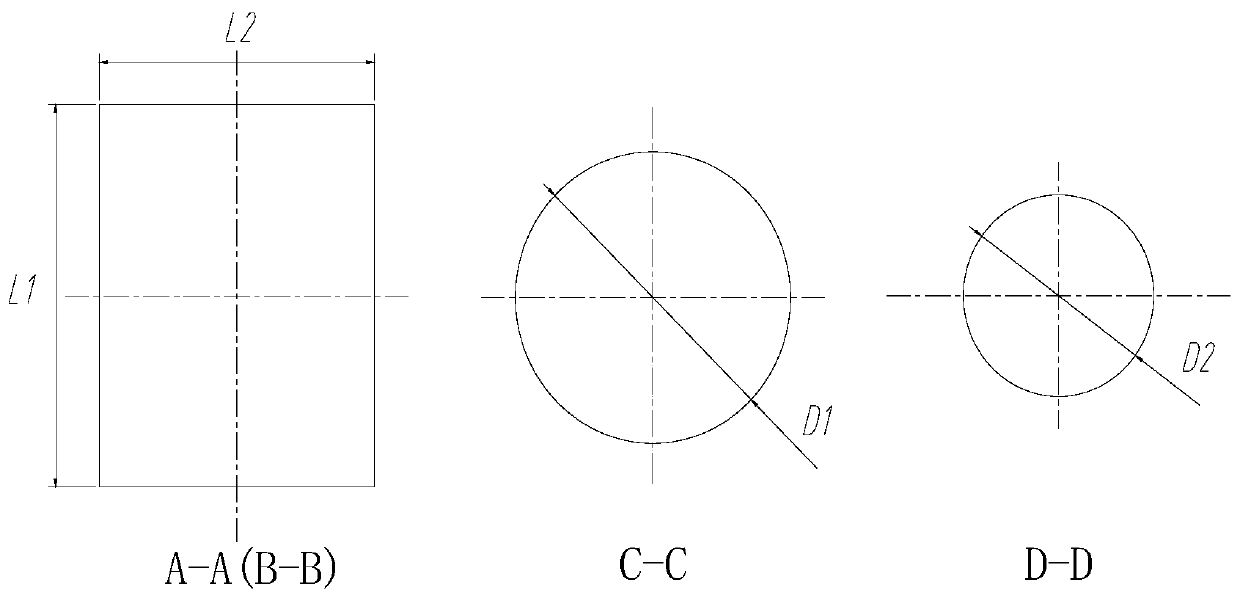

A high-lift bulb tubular pump

A bulb tubular flow pump and high-lift technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as low efficiency, difficult processing, and high manufacturing costs, and achieve less hydraulic loss , avoid hydraulic loss, good flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0069] Example 1, assuming that the outlet diameter D3 of the impeller chamber of the tubular pump is 0.39m, the rated speed of the impeller is 1430r / min, the head of the tubular pump is 7.5m, the measured flow rate of the tubular pump is 262L / s, and the shaft power is 23.86kW. The efficiency of the tubular pump is 81.22%.

example 2

[0070] Example 2, assuming that the outlet diameter D3 of the impeller chamber of the tubular pump is 0.39m, the rated speed of the impeller is 1430r / min, the head of the tubular pump is 8.5m, the measured flow rate of the tubular pump is 249L / s, and the shaft power is 25.23kW. The efficiency of the tubular pump is 82.55%.

example 3

[0071] Example 3, assume that the outlet diameter D3 of the impeller chamber of the tubular pump is 0.39m, the rated speed of the impeller is 1430r / min, the head of the tubular pump is 9.5m, the measured flow rate of the tubular pump is 232L / s, and the shaft power is 26.70kW. The efficiency of the tubular pump is 81.25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com