Method of implementing on line softening annealing of medium, high carbon steel wire using high energy electric pulse

A high-carbon steel wire, softening annealing technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of complex equipment and processes, long heat treatment cycle, high production cost, etc., and achieve short processing time, excellent comprehensive performance and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

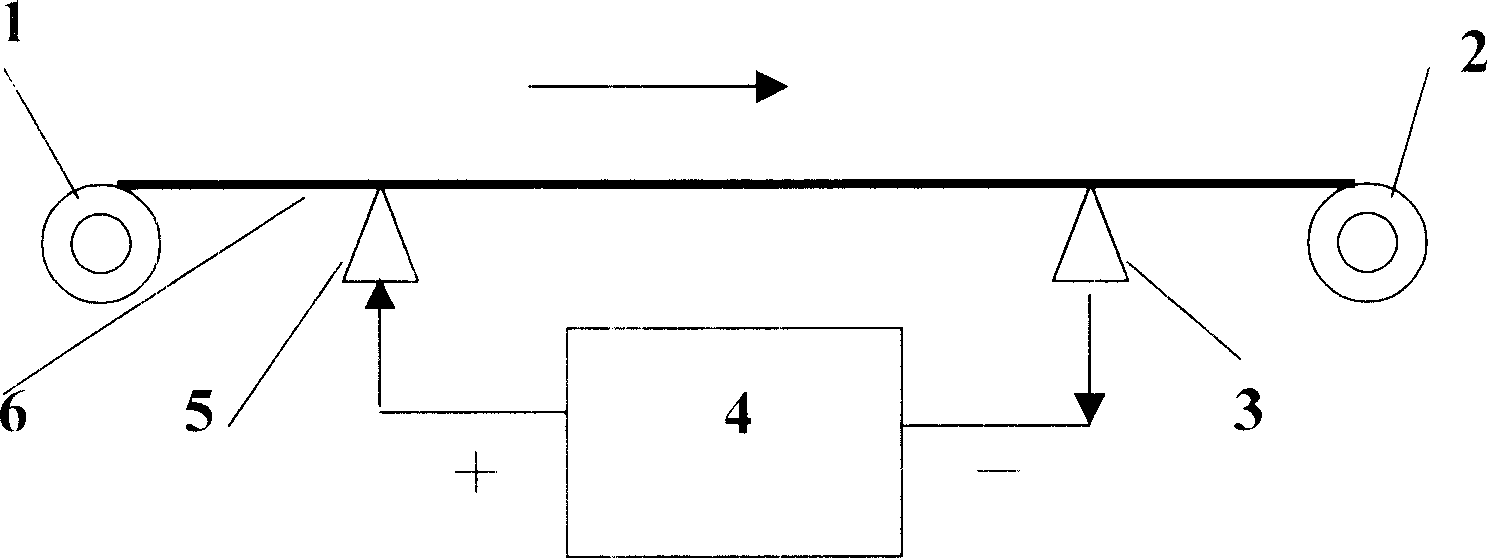

[0024] Example 1: GCr15 steel wire with a diameter of 2.00 mm in the original annealed state is cold drawn for multiple passes, and the diameter of the wire is 1.05 mm. use figure 1 The shown equipment and the high-energy electric pulse online softening annealing process of the present invention process the GCr15 steel wire. figure 2 It is the metallographic structure (spheroidized annealed structure) of GCr15 steel wire before cold drawing deformation hardening, and spherical cementite is evenly distributed in the ferrite matrix. image 3 It is the metallographic structure of GCr15 steel wire after cold drawing deformation and hardening. The ferrite matrix grains are elongated into fibers, and the cementite is still spherical and distributed along the ferrite deformation direction.

[0025] refer to figure 1 , the GCr15 steel wire is driven by the uncoiling device 1 and the rewinding device 2 and is transmitted at a speed of 6m / min or 16m / min in the direction of the arrow....

Embodiment 2

[0029] Example 2: 55 steel wires originally in a work-hardened state, with a diameter of 0.98mm. use figure 1 The equipment shown and the high-energy electric pulse online continuous softening annealing process of the present invention process the 55 steel wire. Figure 5 It is the metallographic structure of 55 steel wire after work hardening, the ferrite grains are elongated into fibers, and the pearlite is distributed along the ferrite deformation direction.

[0030] refer to figure 1 , the 55 steel wire is driven by the uncoiling device 1 and the rewinding device 2 and is transmitted in the direction of the arrow at a speed of 8m / min. The positive and negative poles of the high-energy pulse power supply are respectively connected to the electrodes made of copper-coated nickel layer (the distance between the electrodes is 250mm). The energized zone segment of the 55 steel wire is subjected to continuous softening annealing treatment. The pulse width of the input high-ene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com