Comprehensive utilization method of sea salt bittern

A bittern and sea salt technology, applied to calcium/strontium/barium halides, calcium/strontium/barium sulfates, alkali metal chlorides, etc., can solve the problems of less developed products and high energy consumption, and achieve less cost input, Reasonable route and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

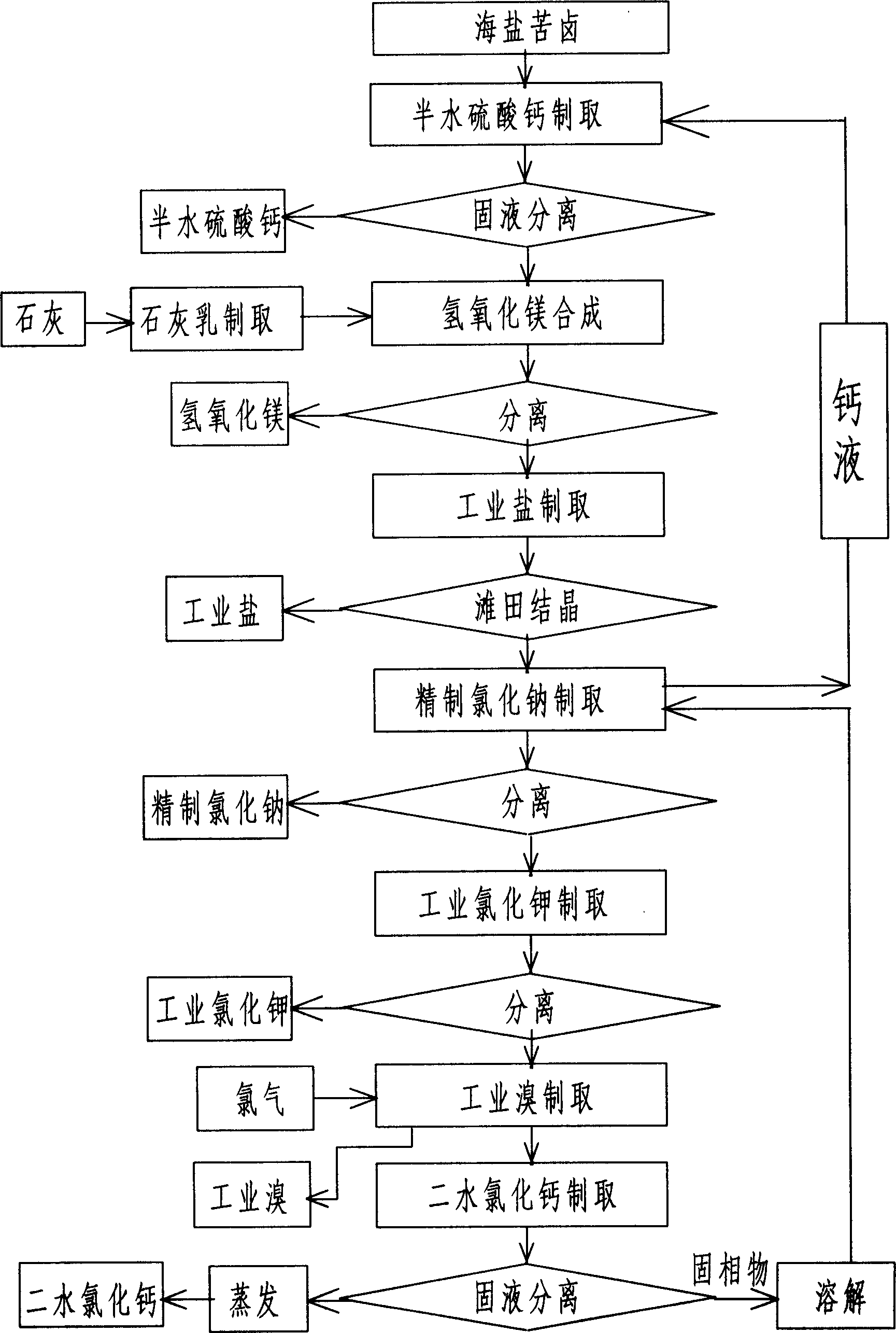

Image

Examples

Embodiment Construction

[0019] The following is an example of actual industrialized trial production: Take 70,000 cubic meters of bittern from sea salt in the salt area and transport it to the brine storage pool. The average test result is 27.2oBé.

[0020] (1), preparation process of calcium sulfate hemihydrate: carry out mixed reaction with calcium liquid after sea salt bittern is filtered to remove impurity treatment, in the Ca that originates from calcium liquid 2+ Ions and SO from sea salt bittern 4 2- The ion molar ratio is 1.3:1, and the reaction temperature is 35-40°C. After mixing evenly, the slurry is separated into solid and liquid to obtain calcium sulfate dihydrate and magnesium liquid. The calcium sulfate dihydrate is washed with water until no Cl is detected in the washing liquid. - As the standard, calcium sulfate dihydrate containing 6-8% of free water was obtained, and then 3530 tons of calcium sulfate hemihydrate was obtained under the condition of 170° C. for dehydration and dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com