Mixed defatting stove and its mixed defatting process

A degreasing process and degreasing furnace technology are applied in the field of mixed degreasing furnace and mixed degreasing process to achieve the effects of increasing productivity, reducing equipment investment and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

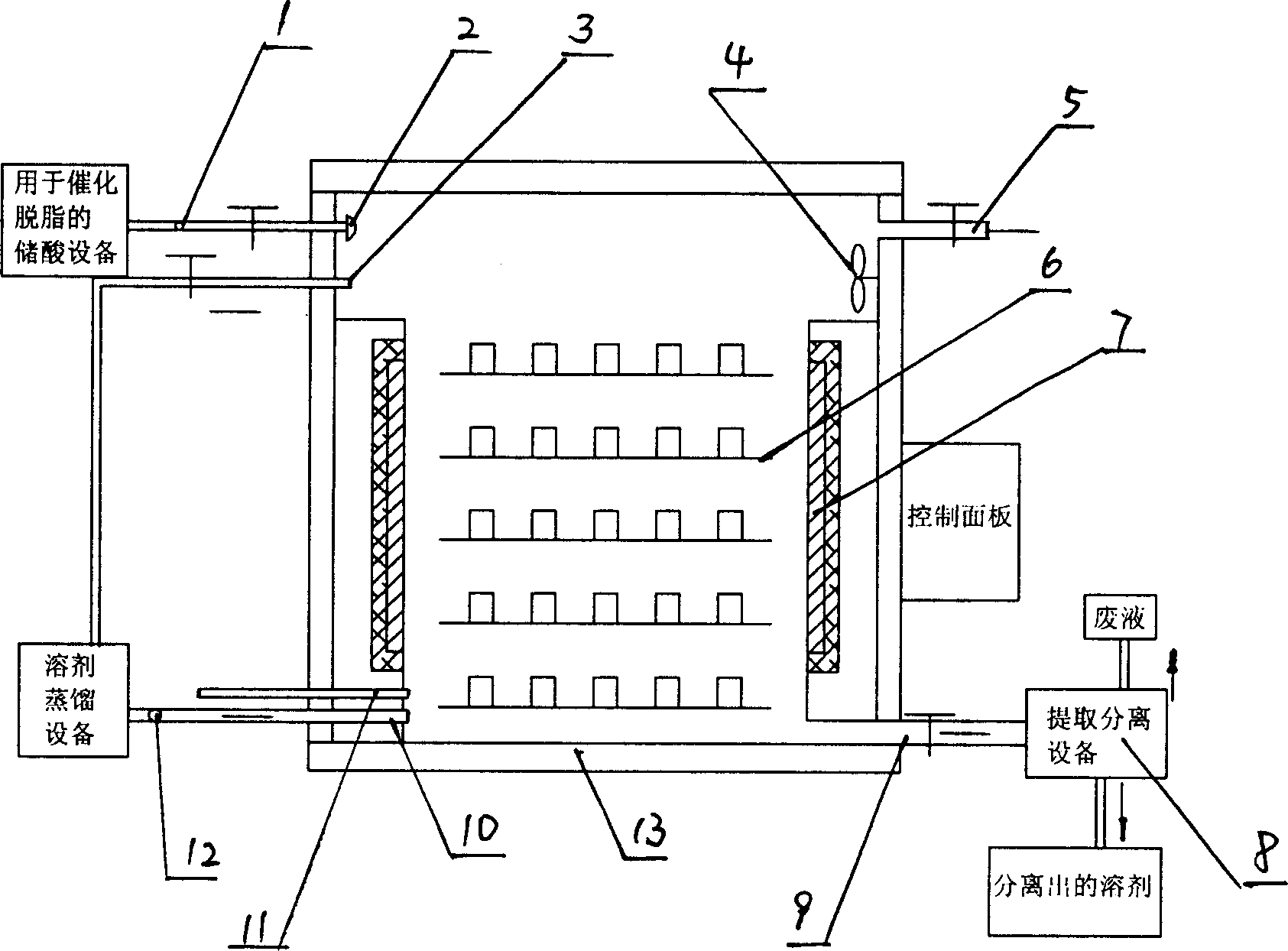

[0022] A mixed degreasing furnace, which is provided with a furnace body 13, a furnace cover is installed on the furnace body 13, a heating device 7 is arranged on the side wall of the furnace body 13, and a heat insulation board is arranged outside the heating device 7. The bottom of the body of furnace 13 is provided with a solvent inlet 10 connected to the solvent storage device through a pump 12, and a solvent outlet 9 is provided corresponding to the solvent inlet 10. The bottom of the body of furnace 13 is also provided with a protective gas inlet 11. The upper part of the body 13 is provided with an exhaust port 5, and the upper part of the body of furnace 13 is also provided with a solvent vapor inlet 3 connected with the solvent distillation equipment, and the upper part of the body of furnace 13 is equipped with a fan 4 which makes the gas in the furnace uniform. The upper part of the furnace body 13 is also equipped with an atomizer 2, and the atomizer 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com