Production of low-voltage-driven liquid-crystal refractive-index grating

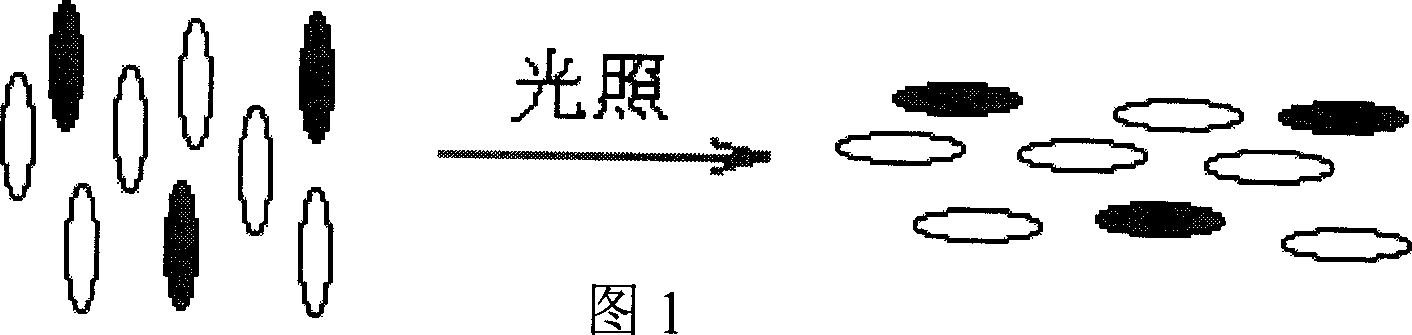

A technology of refractive index grating and low voltage, which is applied in the field of preparation of liquid crystal refractive index grating, which can solve the problem that the difference in refractive index between liquid crystal material and polymer material is not large enough, it is difficult to match TFT or large-scale integrated circuit, polymer and liquid crystal phase Incomplete separation and other problems, to achieve the effect of simple and easy-to-control preparation method, low external environment requirements, and low content requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the present invention more clearly, the preparation process is further described in detail below in conjunction with specific embodiments.

[0024] 1. Preparation of liquid crystal materials doped with photochromic polymers with azo groups

[0025] First weigh 2.5 grams of oriented nematic liquid crystal TEB30A, and then add 0.013 grams of photochromic polymer material with azo groups therein. The selected nematic liquid crystal TEB30A is a product of Shijiazhuang Like Company. The added photochromic polymer material with an azo group has a polymer structure with an azophenyl group at one end of the side chain. The molecular formula of a representative photochromic polymer material with an azo group of the present invention is:

[0026]

[0027] After the addition, stir at room temperature until the mixture is homogeneous.

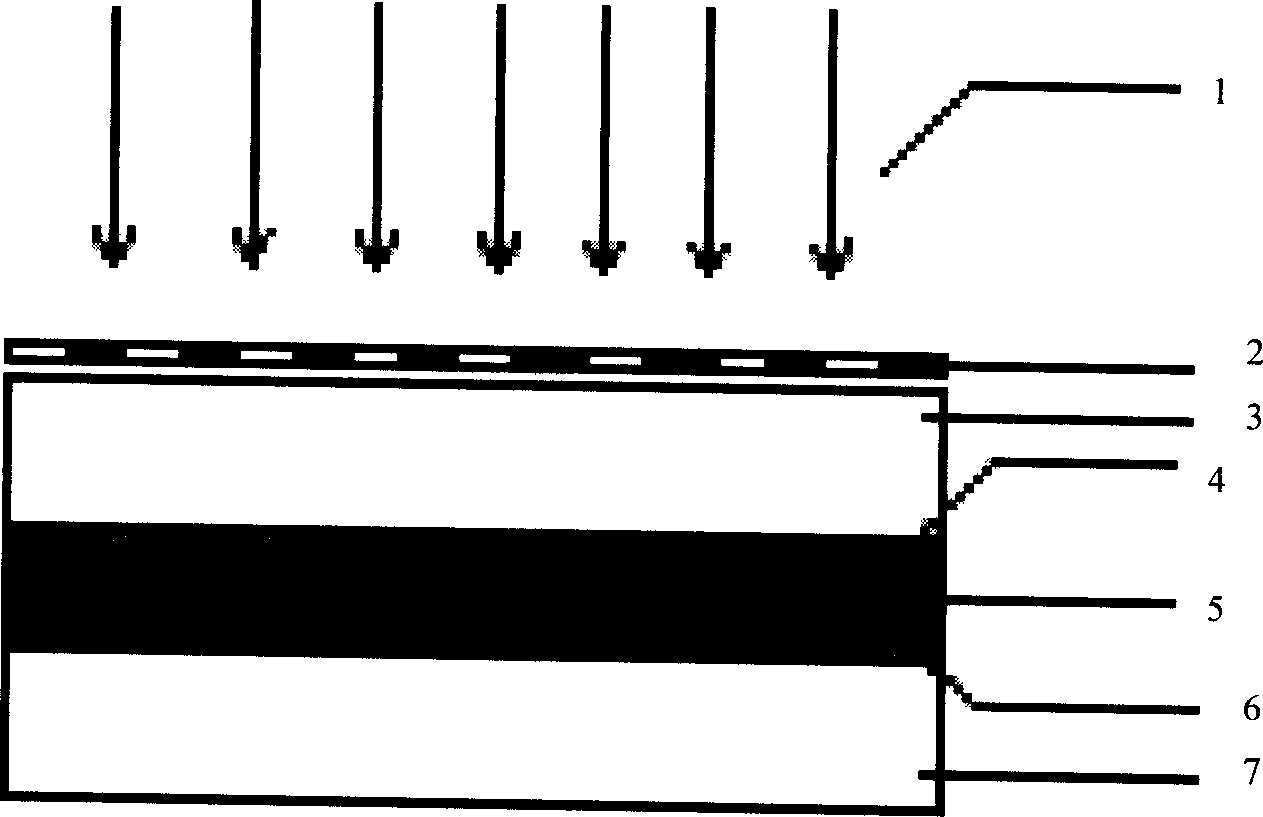

[0028] 2. Preparation of liquid crystal cell

[0029] The ITO glass with a transparent conductive film with a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com