Low-temperature alkaline-solution synthesis of oxygen metal inorganic compound monocrystal nano-material

An inorganic compound, single crystal nanotechnology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of small output, difficult to repeat, difficult to industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

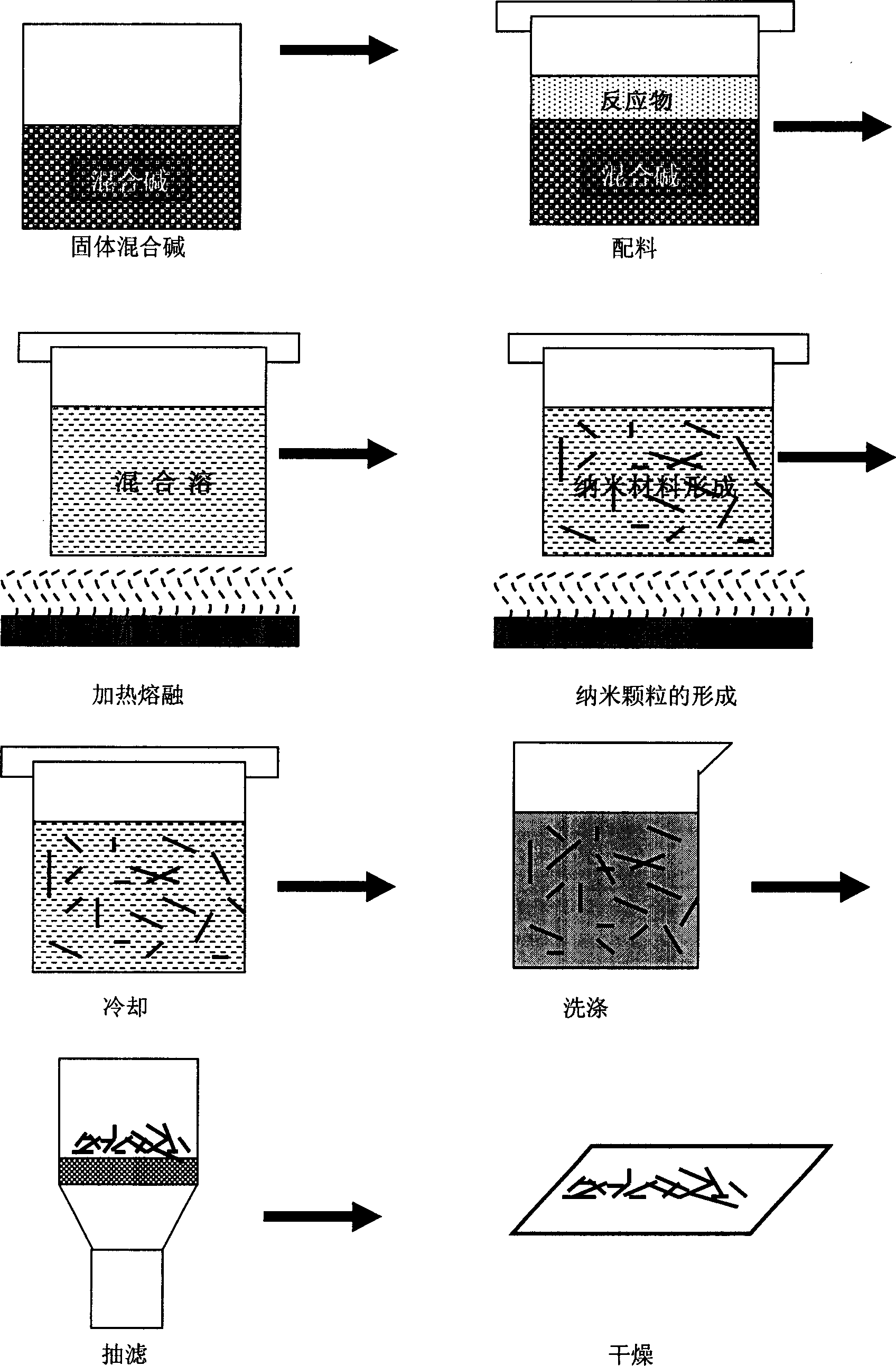

Method used

Image

Examples

Embodiment 1

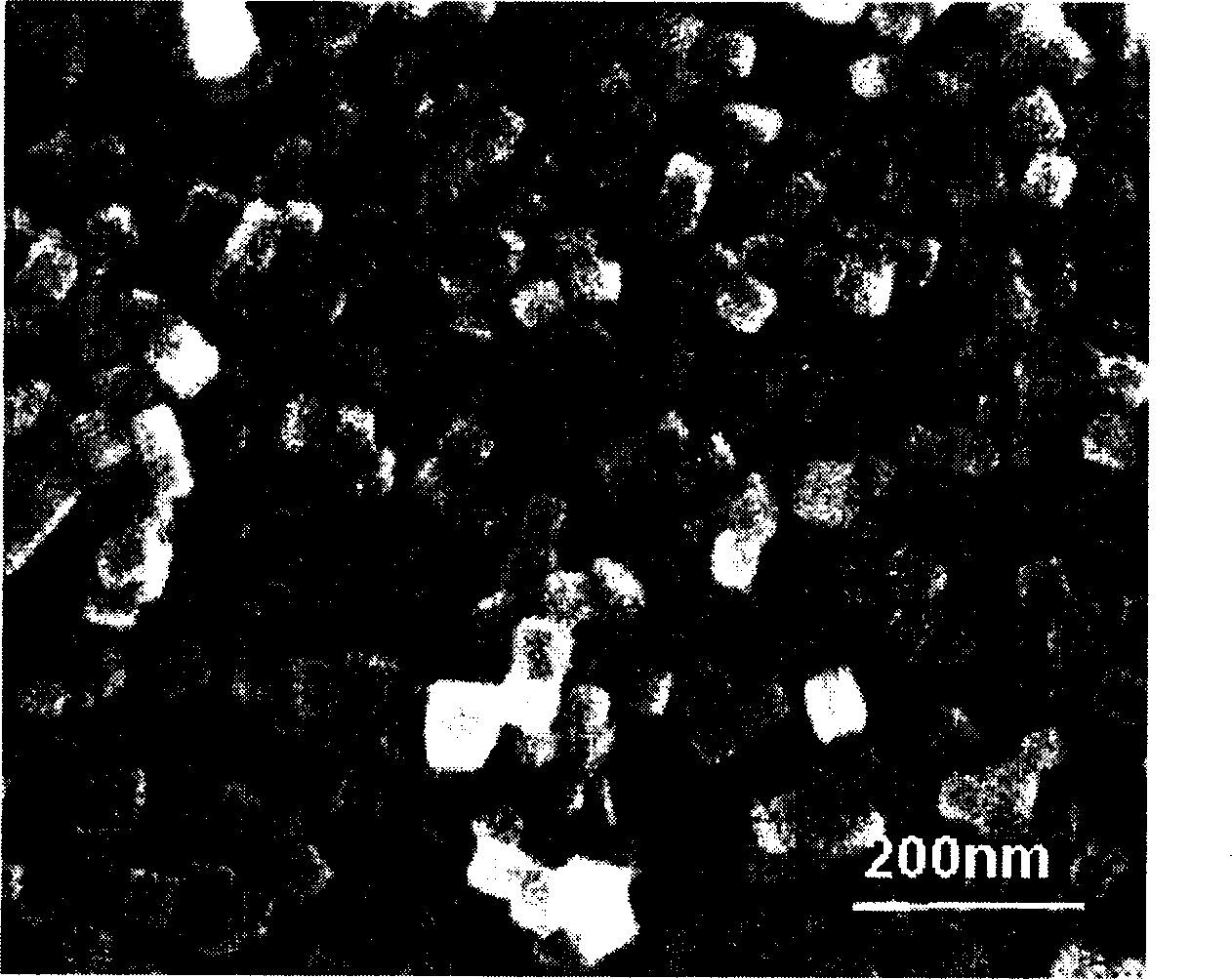

[0032] Synthesis of Barium Titanate Nanocubes

[0033] 1. Ingredients:

[0034] (1) Weigh 10 grams of KOH and 7 grams of NaOH into a polytetrafluoroethylene container with a volume of 25 milliliters.

[0035] (2) Add 1 mmol of barium chloride and 1 mmol of titanium dioxide to the alkali in the above polytetrafluoroethylene container.

[0036] (3) Teflon container is sealed to keep the reaction process clean.

[0037] 2. Heating and melting:

[0038] Heat the muffle furnace or oven to 210°C, and put the sealed polytetrafluoroethylene container into the heating device. Keep the heating equipment warm for 1 hour and stir to mix the melt and reactants evenly.

[0039] 3. Constant temperature reaction:

[0040] The reactants in the solution were reacted under the above conditions for 48 hours until the reaction was completed.

[0041] 4. Cooling:

[0042] The reaction vessel was taken out from the heating device, and cooled in an ice-water mixture until the reaction vessel dro...

Embodiment 2

[0049] Synthesis of Barium Strontium Titanate Nanocubes

[0050] 1. Ingredients:

[0051] (1) Weigh 10 grams of KOH and 7 grams of NaOH into a polytetrafluoroethylene container with a volume of 25 milliliters.

[0052] (2) Add 0.5 mmol of barium chloride, 0.5 mmol of strontium chloride and 1 mmol of titanium dioxide to the alkali in the above polytetrafluoroethylene container.

[0053] (3) Teflon container is sealed to keep the reaction process clean

[0054] 2. Heating and melting:

[0055] Heat the muffle furnace or oven to 220°C, and put the sealed polytetrafluoroethylene container into the heating device. Keep the heating equipment warm for 1 hour and stir to mix the melt and reactants evenly.

[0056] 3. Constant temperature reaction:

[0057] The reactants in the solution were reacted under the above conditions for 60 hours until the reaction was completed.

[0058] 4. Cooling:

[0059] The reaction vessel was taken out from the heating device, and cooled in an ic...

Embodiment 3

[0066] Synthesis of Iron Tetroxide Nanocubes and Nanocube Columns

[0067] 1. Ingredients:

[0068] (1) Weigh 10 grams of KOH and 7 grams of NaOH into a polytetrafluoroethylene container with a volume of 25 milliliters.

[0069] (2) Add 1 mmol of ferric chloride and 1 mmol of ferric oxide to the alkali in the above polytetrafluoroethylene container.

[0070] (3) Teflon container is sealed to keep the reaction process clean.

[0071] 2. Heating and melting:

[0072] Heat the muffle furnace or oven to 200°C, and put the sealed polytetrafluoroethylene container into the heating device. Keep the heating equipment warm for 1 hour and stir to mix the melt and reactants evenly.

[0073] 3. Constant temperature reaction:

[0074] The reactants in the solution were reacted under the above conditions for 70 hours until the reaction was completed.

[0075] 4. Cooling:

[0076] The reaction vessel was taken out from the heating equipment, and cooled in air until the reaction vessel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com