Degassing apparatus and ultrasonic wave washing apparatus using the same

A technology of degassing device and cleaning device, applied in the field of ultrasonic cleaning device and degassing device, can solve the problems of cost and labor required for device maintenance and management, high price of degassing membrane, and high device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

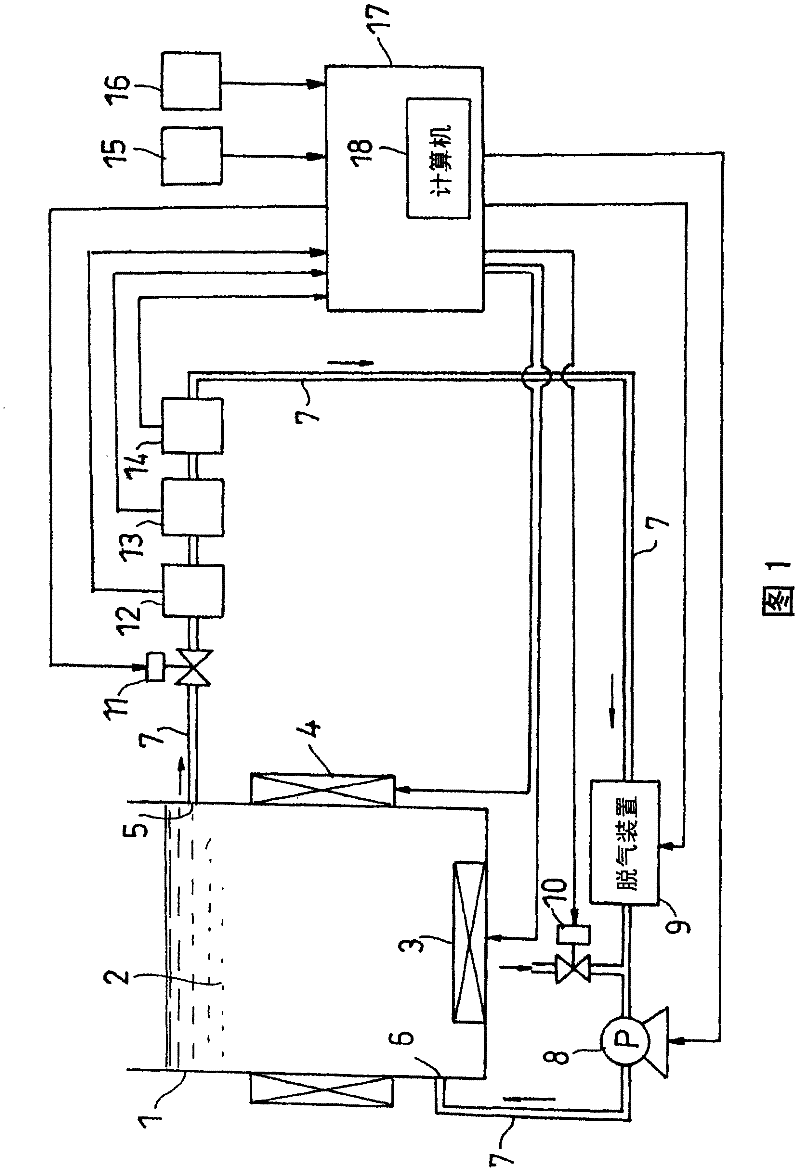

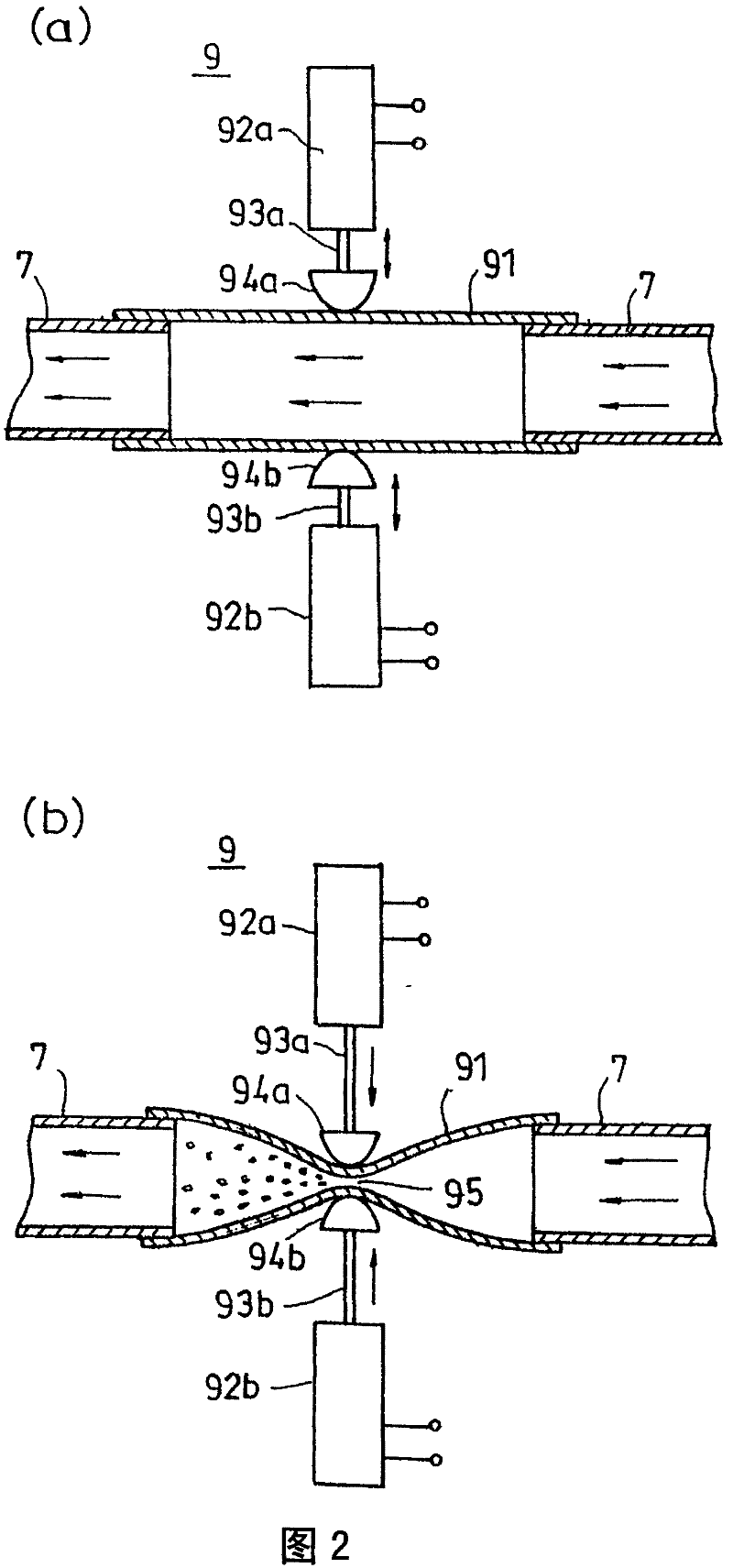

[0065] figure 1 It is a figure which shows one embodiment of the ultrasonic cleaning apparatus of this invention, figure 2 It is a figure which shows the structure of the degassing apparatus used in this embodiment.

[0066] exist figure 1 Among them, 1 is a cleaning tank filled with cleaning solution 2, and an ultrasonic generator 3 is attached to the bottom of the cleaning tank 1. In addition, a heater (liquid temperature adjustment mechanism) 4 is attached around the cleaning tank 1 to adjust the temperature of the cleaning liquid 2 .

[0067] The suction port 5 of the cleaning liquid is opened at the upper position of the cleaning tank 1, and the discharge port 6 of the cleaning liquid is opened at the lower position on the opposite side to the suction port 5, and these suction ports 5 and the discharge ports 6 are connected by piping such as a conduit. , and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com