Device for detecting detected object

A detection body and equipment technology, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, can solve the problem that the conveyor belt is not suitable for cylindrical detection bodies, and achieve simple and reliable placement and removal, and simple maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

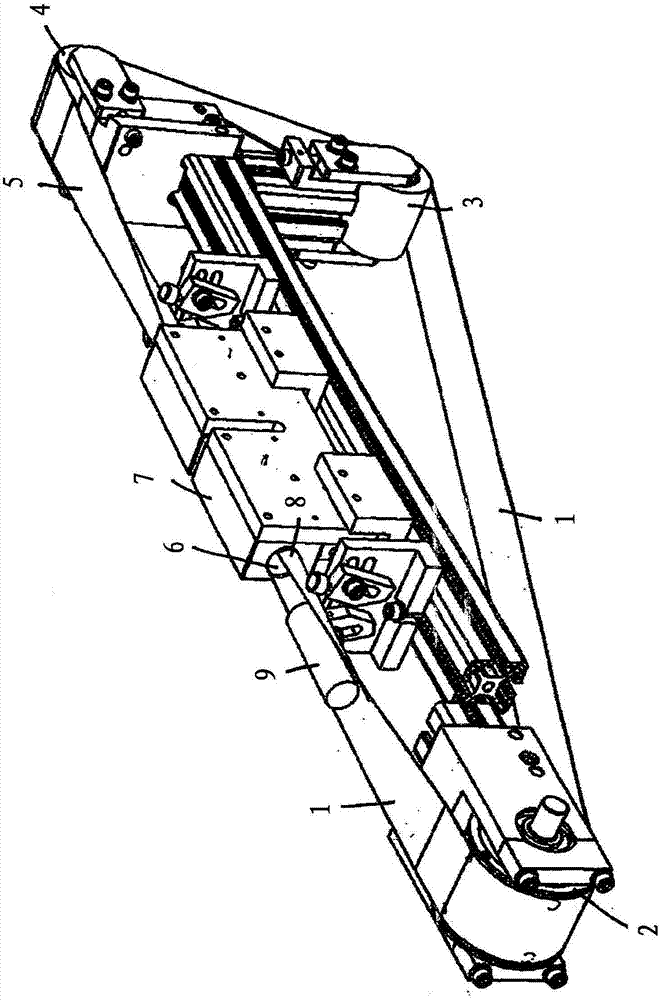

[0010] The flat conveyor belt 1 is guided as an endless endless belt via two, three or more deflection rollers 2 , 3 , 4 . The electrically driven conveyor belt 1 forms an upper horizontal region 5 which extends through the test channel 6 of the eddy current test device 7 .

[0011] The detection channel 6 has a cylindrical shape, the horizontal axis of which is parallel to the longitudinal direction of the horizontal strip region 5 . The conveyor belt 1 is deformed into a groove 8 through the detection channel 6, and the groove is a partial circle at an angle of 180-300 degrees in its cross section, so the groove 8 of the conveyor belt surrounds a cylindrical detection body 9, and the detection The bodies are placed on the conveyor belt 1 in such a way that the longitudinal direction of the test bodies, in particular their longitudinal axes, is parallel to the longitudinal direction of the conveyor belt 1 and preferably coaxial to the axis of the test channel 6 .

[0012] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com