Carrying device for an apron drafting system

A technology of bearing mechanism and drafting device, applied in the direction of drafting equipment, spinning machine, free-end spinning machine, etc. Issues such as adverse effects on yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

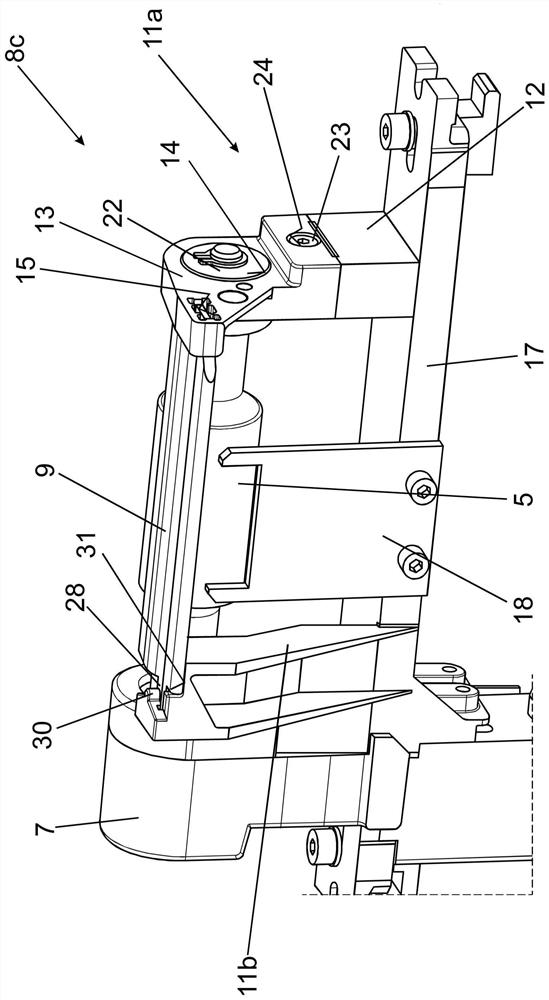

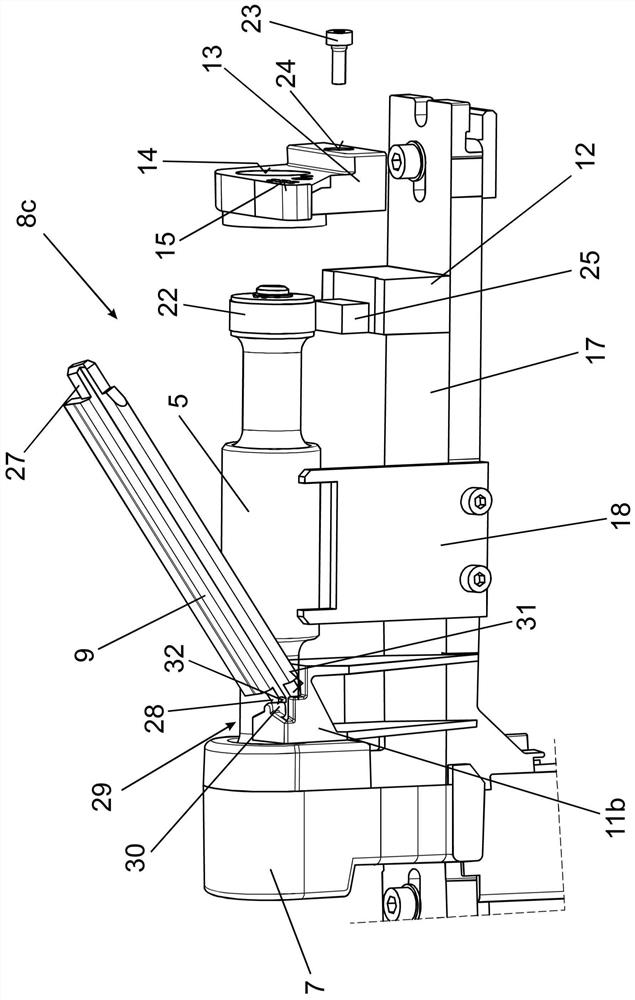

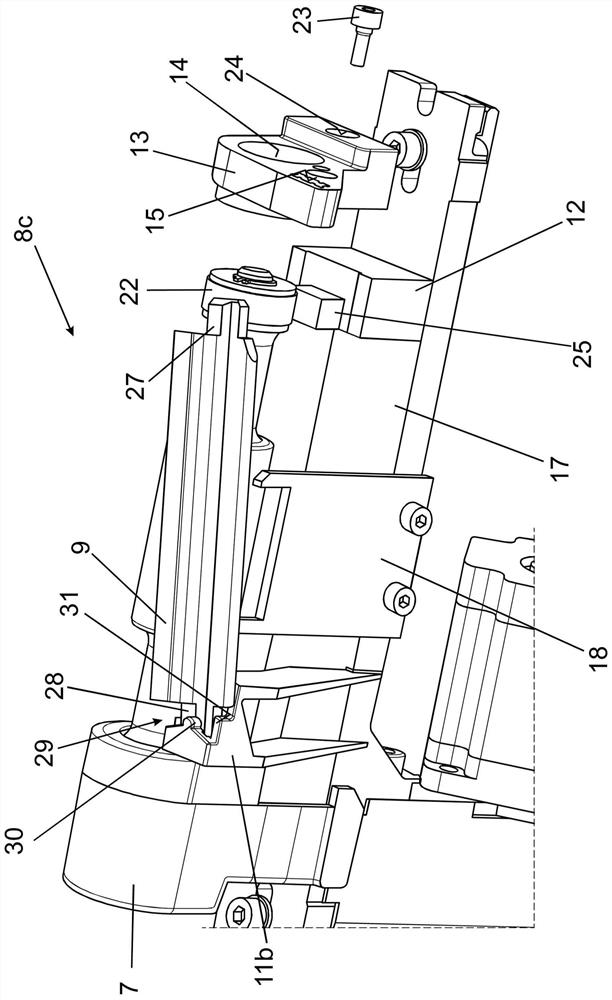

[0071] Figure 5 The apron drafting device 1 of the spinning station of the spinning machine, which is not shown here, is shown in a perspective view, which can be fixed to the spinning machine by a lock hook 21. The apron drafting device 1 here has an upper part 19 of the drafting device, which is hingedly connected to the lower part 2 of the drafting device, where the rotation is performed by the operation of the handle 20.

[0072] In the apron drafting device 1, such as Figure 5 In the working position shown, the upper part 19 of the drafting device abuts the lower part 2 of the drafting device with four upper rollers arranged one after another in the direction of movement of the fiber sliver not shown here through the apron drafting device 1 The corresponding driven lower rollers 3, 4, 5, 6. The input roller 3 that first contacts the fiber sliver belongs to the lower rollers 3, 4, 5, 6. The input roller is driven by the roller driving mechanism 7 and forms the first lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com