Nir absorption and color compensating compositions

A composition, C1-C20 technology, applied in chemical instruments and methods, identification devices, other chemical processes, etc., can solve the problem of red light color purity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

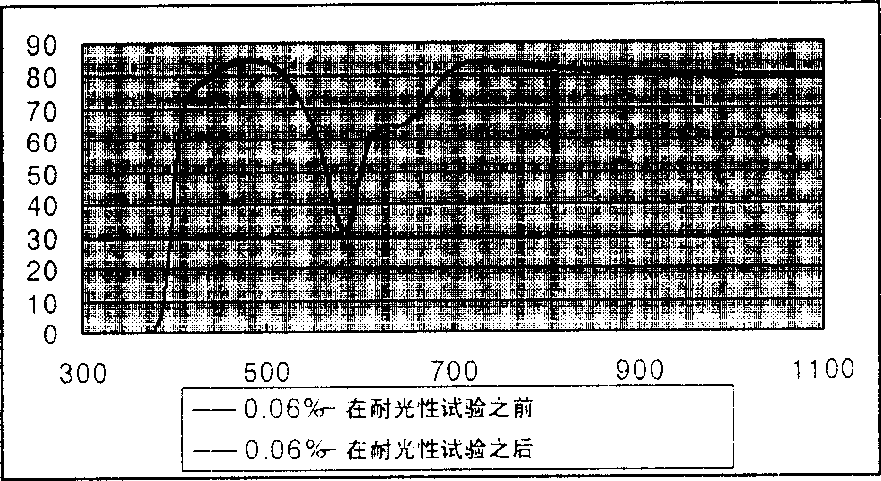

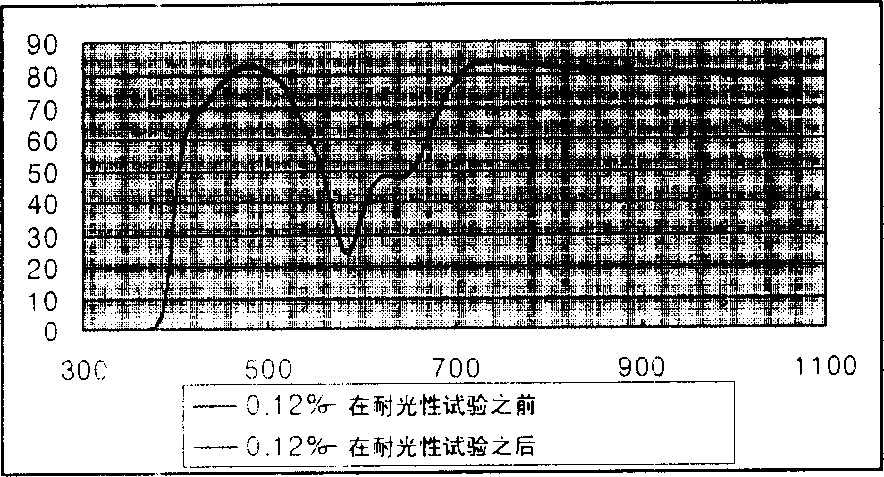

[0120] Example 1: Preparation of color compensation film using anthraquinone dye and cyanine dye

[0121] Under stirring, based on the total solution, 0.06 wt% or 0.12 wt% of 1,4-diaminoanthraquinone dye (Green-5B available from M-Dohmen) for improving the lightfastness of cyanine dyes and 0.02 wt% of a cyanine dye (HAO-01 available from Hayashibara Biochemical) for absorbing visible light at about 585 nm was added to a mixture of 6.0 g of acrylic polymer binding resin (GS-1000 available from Soken) and 4.0 g of 1 , 3-dioxolane solvent (available from Aldrich) in a solution to prepare a uniform coating solution. Next, the coating liquid thus prepared was applied onto the primer-treated surface of an optical film (A4100 available from Toyobo) by using a wire bar. Thereafter, the coated film was dried at 80° C. for 1 minute by using hot air to prepare a film having a 7 μm thick color compensation layer.

Embodiment 2

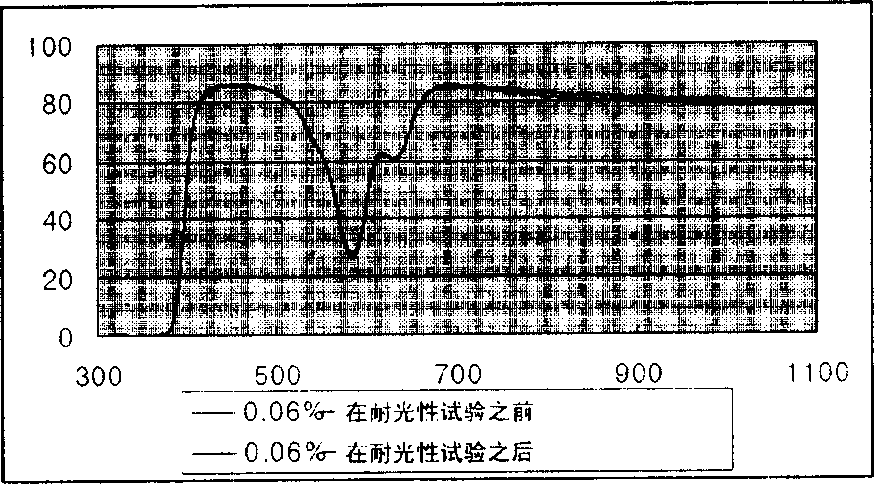

[0122] Example 2: Preparation of color compensation film using anthraquinone dye and cyanine dye (2)

[0123] Under stirring, based on the total solution, 0.06 wt% or 0.12 wt% of 1,4-diaminoanthraquinone dye (available from M-Dohmen as Blue-RR) for improving the light fastness of cyanine dyes and 0.02 wt% of a cyanine dye (HAO-01 available from Hayashibara Biochemical) for absorbing visible light at about 585 nm was added to a mixture of 3.5 g of acrylic polymer binding resin (IR-G205 available from Nippon Shokubai) and 6.5 g A coating solution was prepared in a solution consisting of 2-butanone (available from Aldrich). After that, the coating liquid thus prepared was applied onto the primer-treated surface of an optical film (A4100 available from Toyobo) by using a wire bar coater. Next, by using hot air, the coated film was dried at 80° C. for 1 minute to prepare a film having a color compensation layer with a thickness of 7 μm.

Embodiment 3

[0124] Example 3: Preparation of NIR absorbing film using anthraquinone dye and cyanine dye

[0125] Under stirring, based on the total solution, 0.06 wt% of 1,4-diaminoanthraquinone dye (Blue-AP available from YaBang) for improving the lightfastness of cyanine dyes and 0.03 wt% of absorbing A cyanine dye (TZ-115 available from AsahiDenka) with NIR at about 850 nm was added to a solution consisting of 6.0 g of acrylic polymer binding resin (available from Soken's GS-1000) and 4.0 g of toluene, A coating liquid is prepared. Next, the coating liquid thus prepared was applied onto the primer-treated surface of an optical film (A4100 available from Toyobo) by using a wire bar coater. Next, by using hot air, the coated film was dried at 80° C. for 1 minute to prepare a film having a color compensation layer with a thickness of 7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com