Dropping pipetype granular crystal manufacturing apparatus and granular crystal manufacturing method

A manufacturing device and granular technology, which is applied in the field of drop-tube granular crystal manufacturing devices, can solve the problems of small number of droplets and difficulty in mass production of spherical crystals, and achieve the effects of increasing production volume, efficient mass production of crystals, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

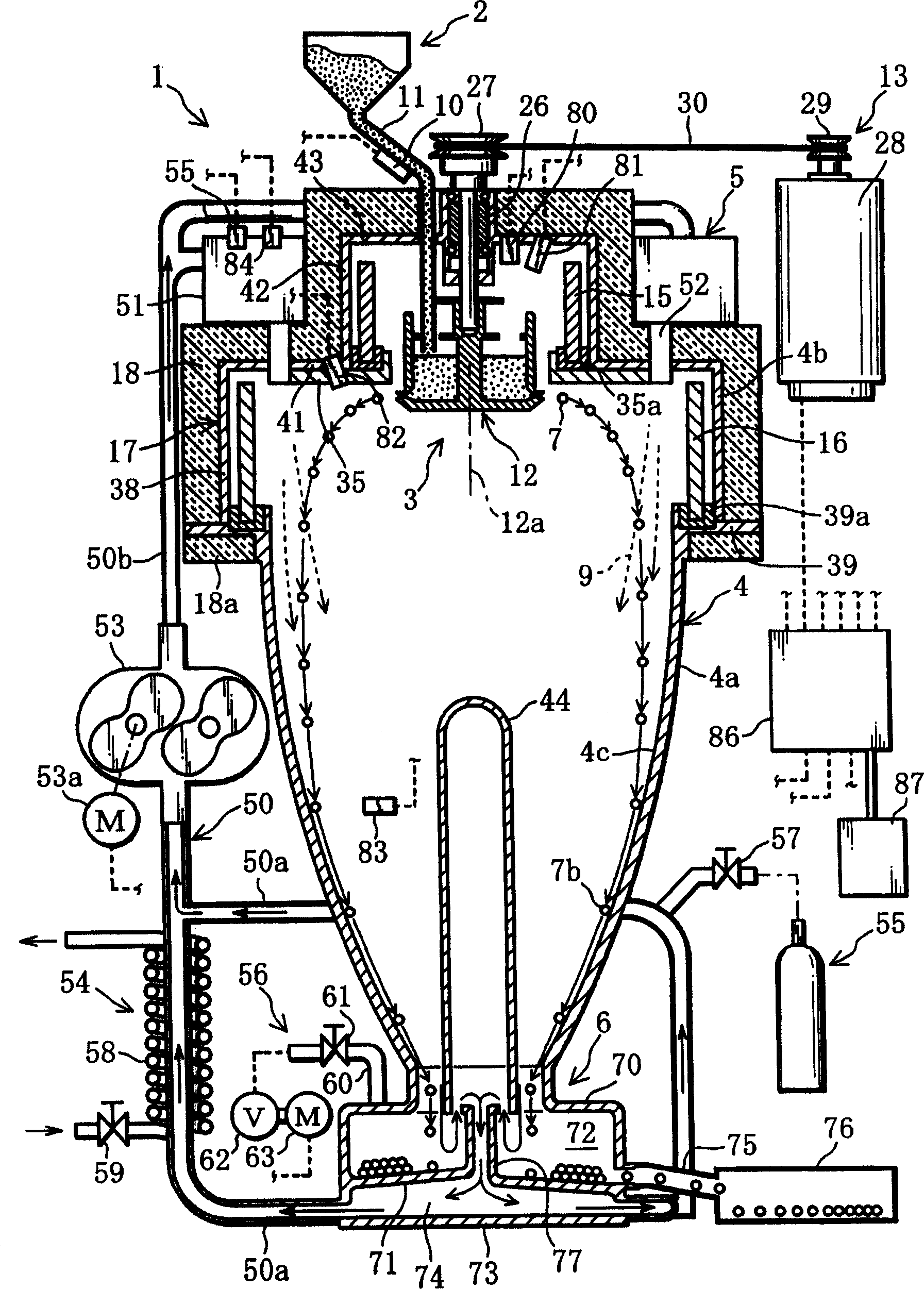

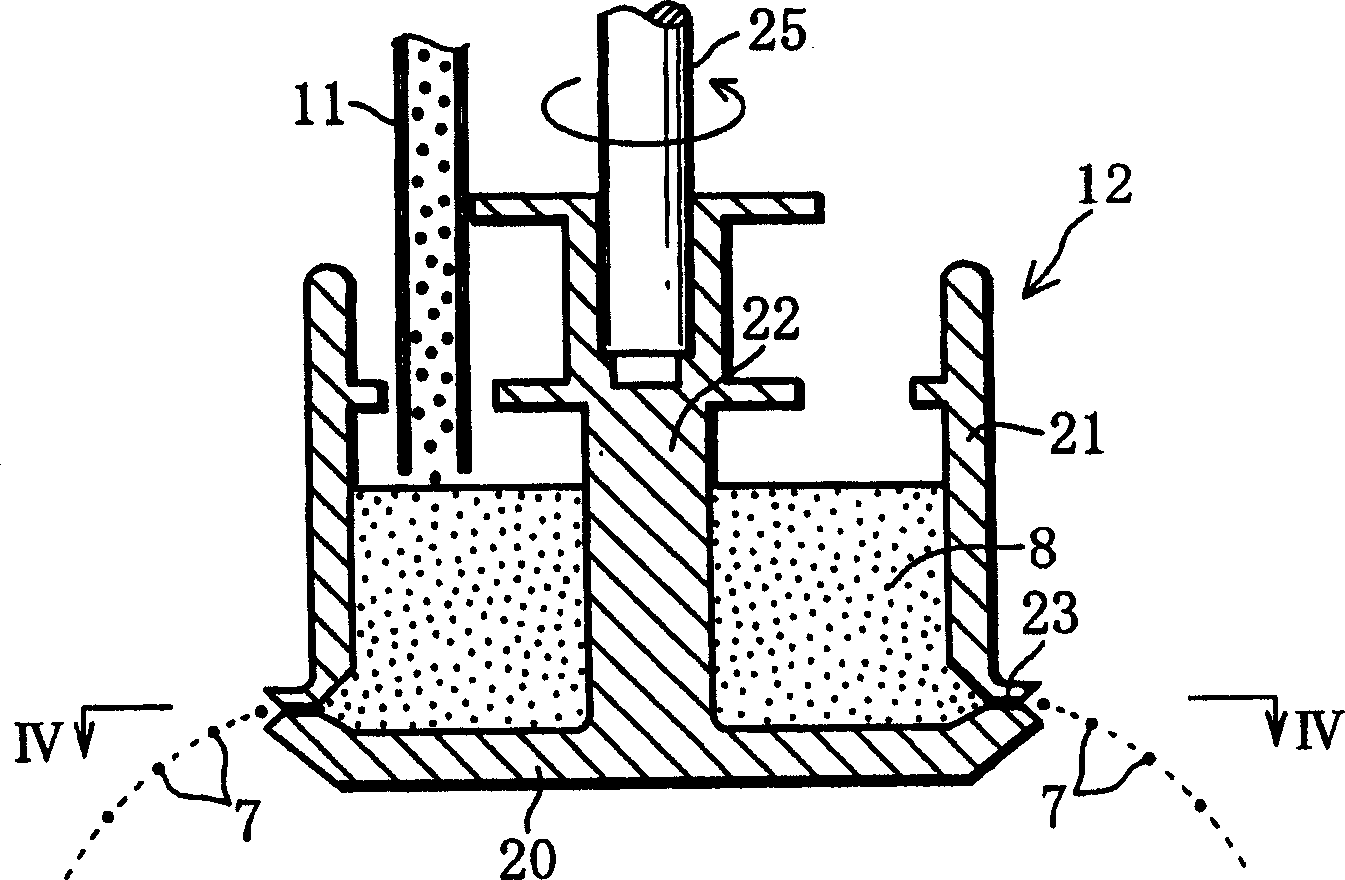

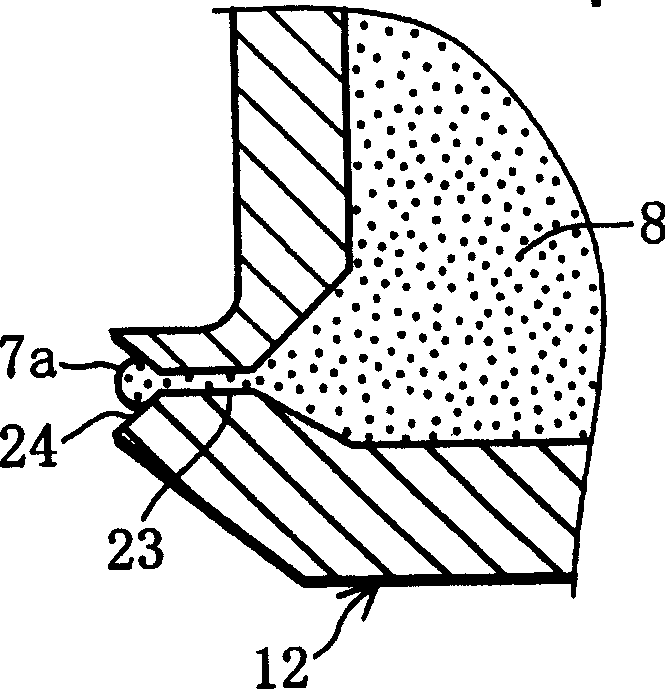

[0049] Hereinafter, a preferred embodiment for carrying out the present invention will be described with reference to the drawings.

[0050] In this down-tube type granular crystal manufacturing apparatus, the raw material of the inorganic material is melted in the rotary crucible, and the granular liquid droplets are discharged in a horizontal or substantially horizontal direction from a plurality of nozzles of the crucible, and the granular liquid droplets are placed in the down-tube Freely falling together with the air flow for cooling, the liquid droplets in the supercooled state contact the inner wall of the downcomer to solidify rapidly, and continuously produce crystals composed of single crystals of roughly spherical inorganic materials. On the other hand, the size of the roughly spherical crystals is about 600 to 1500 μm in diameter.

[0051] In this embodiment, a p-type or n-type silicon semiconductor is used as an inorganic material, and a down-tube granular crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com