Net cage bait feeding machine unloading device

A bait feeder and cage technology, which is applied to heating devices, dryers, counting mechanisms/items, etc., can solve the problems of difficult cleaning of the internal components of the material box, reduce the utilization rate of bait, increase production costs, etc., and achieve increased utilization. The effect of automatic calculation of the rate and the amount of bait, and the increase of the falling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

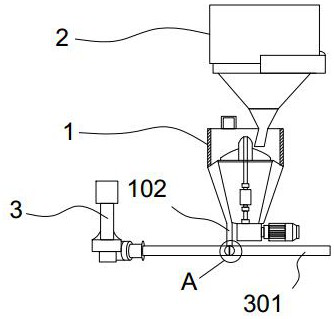

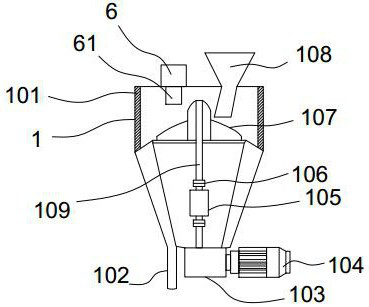

[0028] see Figure 1-6 As shown, the feeding device of the net cage bait throwing machine includes a counting device 1, a bait box 2 is installed above the counting device 1, and the lower end of the counting device 1 communicates with the bait feeding pipe 301 through the discharge pipe 102, and the discharge pipe 102 is connected to the bait feeding pipe 301. Pipe 301 joints are provided with movable rod 4 and are vertically arranged on the inner wall of bait-throwing pipe 301, and movable rod 4 side surfaces are uniformly connected with rotating blades 5, and one end of bait-throwing pipe 301 is provided with Roots blower 3. By installing a counting device at the lower end of the bait box, the counting device can automatically calculate the amount of bait during the feeding process of the bait box. At the connection between the discharge pipe and the bait pipe, a movable rod is arranged vertically on the inner wall of the bait pipe. Rotating blades are evenly distributed on...

Embodiment 2

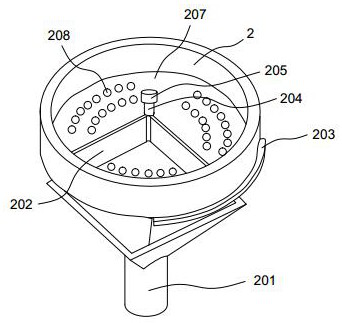

[0042] The working principle of the feeding device of the net cage bait throwing machine of the present invention is: put the bait in the bait box 2, start the second motor 205 through the control panel 6, and drive the baffle plate 202 on the connecting rod 204 to rotate under the second motor 205 , fall into the counting hole 208, the bait is stirred and screened, the bait after screening falls into the counting device 1, the motor 104 at the lower end of the counting device 1 is started, and the rotating shaft 109 provided with the counting device 1 is driven to rotate, thereby driving The rotary wheel 107 rotates, and the speed reducer 103 provided is used to control the rotational speed. The torque sensor 105 installed on the rotating shaft 109 detects the torque received by the rotary wheel 107, and obtains the Coriolis torque suffered by the feed, which is measured by the reducer 103 And feedback, adjust the speed of the motor 104, obtain the instantaneous speed of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com