Thick oil exploiting coal firiag steam boiler

A steam injection boiler and coal-fired technology, which is applied to steam boilers, barrel-type steam boilers, and mining fluids, can solve problems such as inability to adapt to coal-fired working conditions and work requirements, irregular shapes, etc., and reduce heavy oil production. Cost, safe and reliable work, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is provided by the following embodiments, and the present invention will be further described below in conjunction with the accompanying drawings.

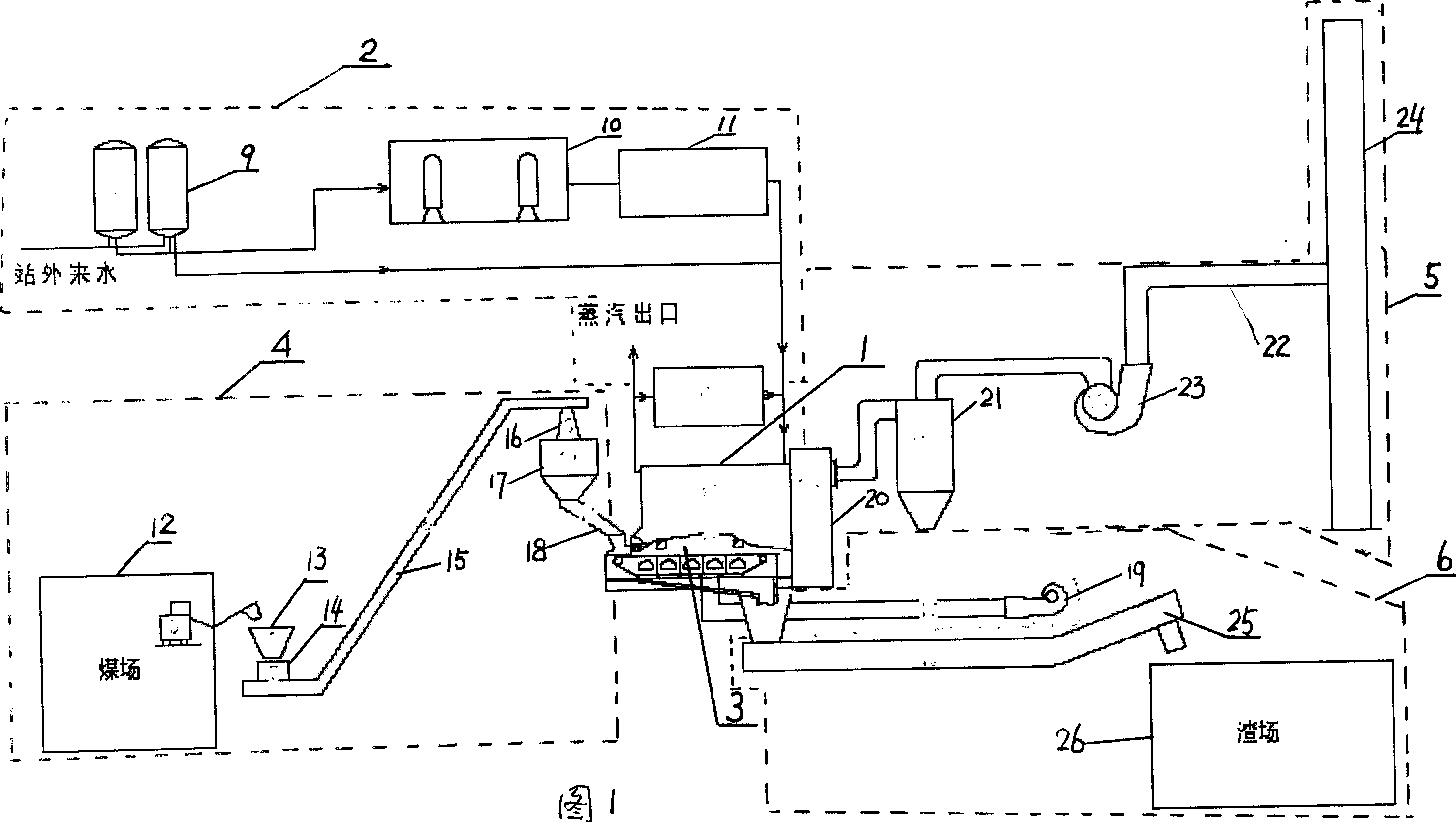

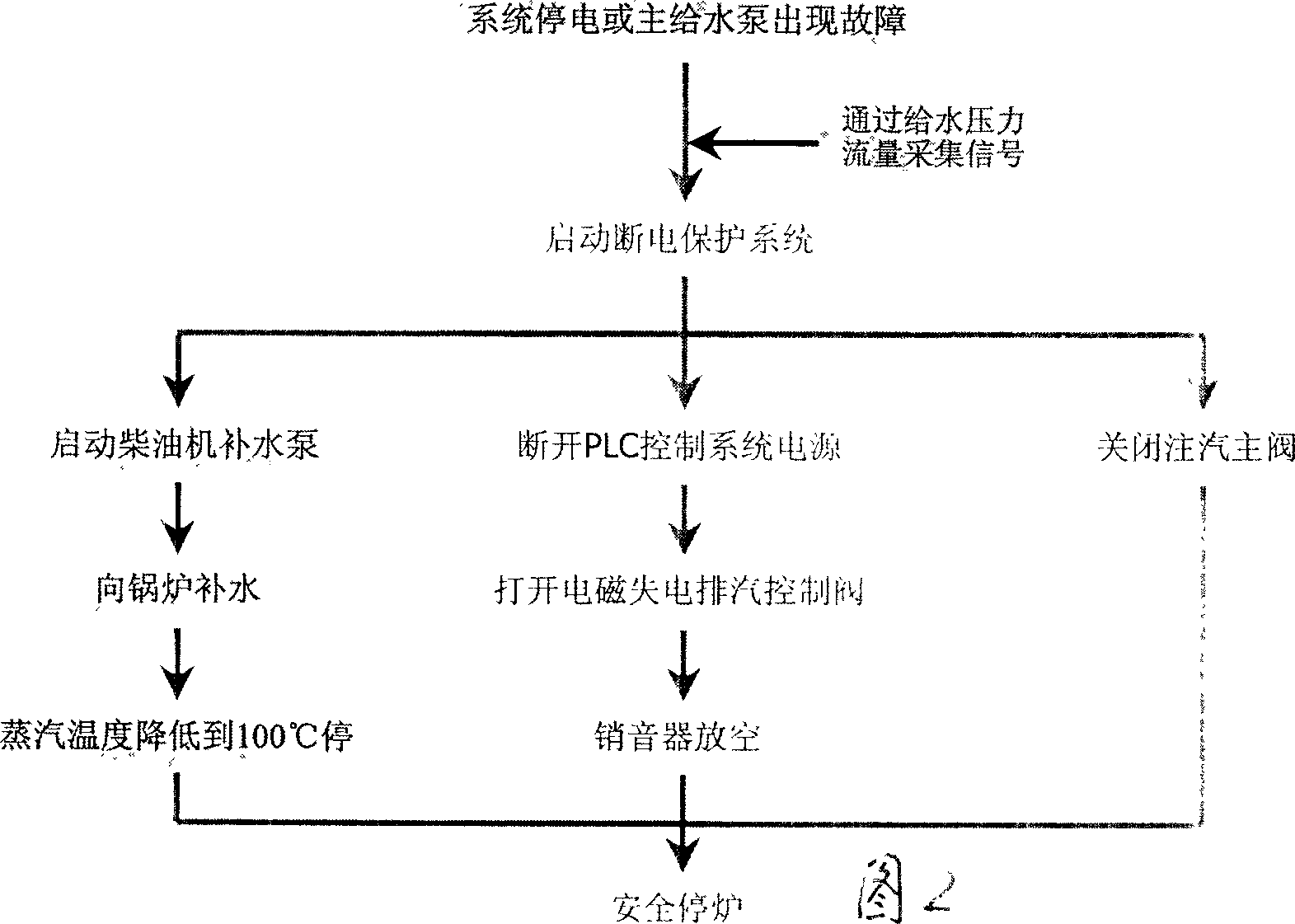

[0016] As shown in the figure, the present invention is composed of a boiler body 1, a water vapor system 2, a fuel system 3, a combustion system 4, a flue gas system 5, an ash system 6, a control system 7 and a power-off protection system 8, and its process flow connection relationship As follows: the water supply line and the steam transmission line of the steam system 2 are respectively connected to the water inlet and the steam outlet of the boiler body 1; the fuel system 3 supplies coal to the combustion system 4 by the layered coal feeder placed in front of the boiler body 1; The combustion system 4 is supplied to the upper, middle and lower layers of the boiler body 1 by the layered coal feeder according to the coal particle size, and is burned in the high and low temperature combustion chambers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com