Hydraulic empty container piling crane

A technology for stackers and containers, applied to lifting devices, etc., can solve problems such as increased operating costs, large power waste, and low work efficiency, and achieve the effects of improving operational safety and reliability, improving transmission efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

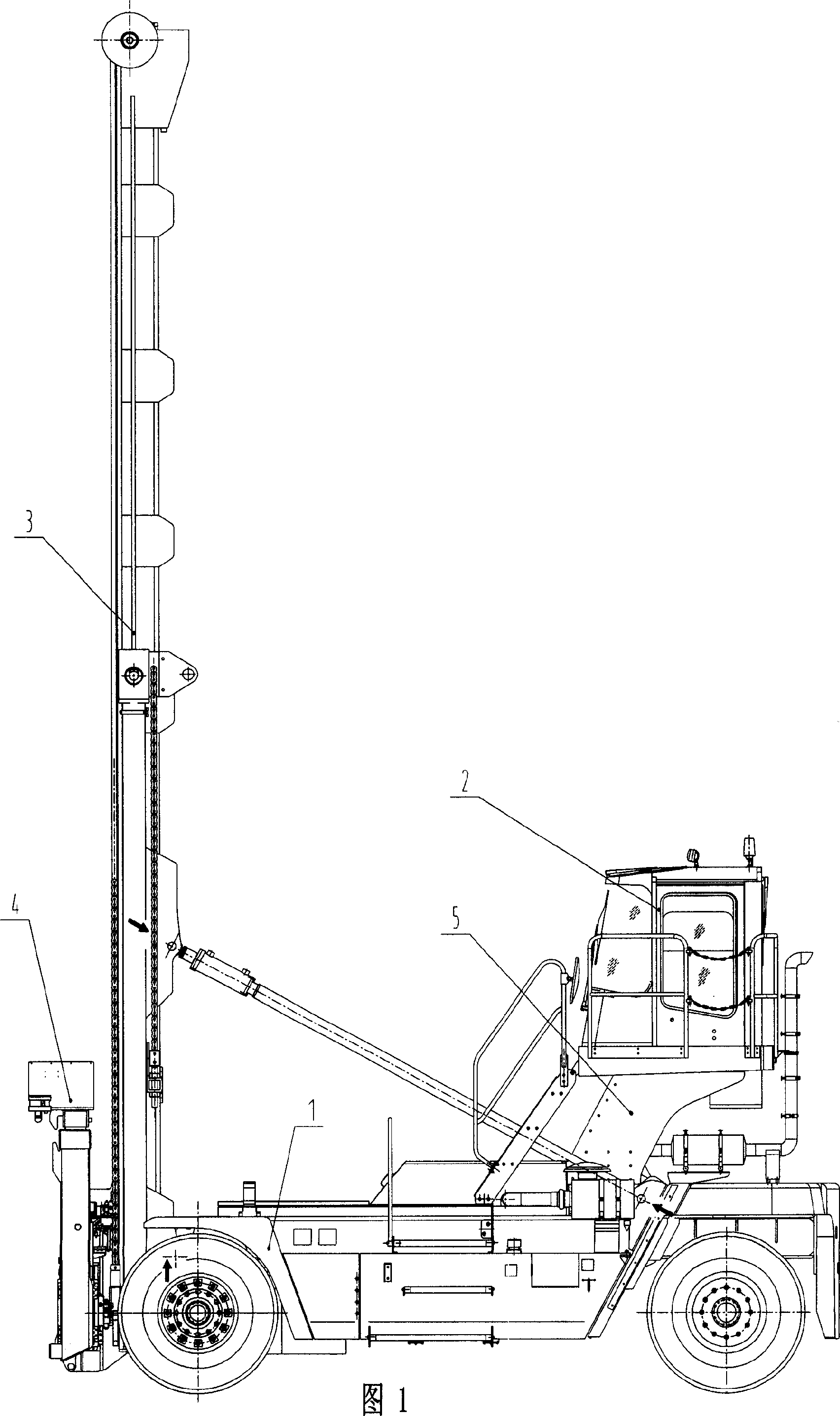

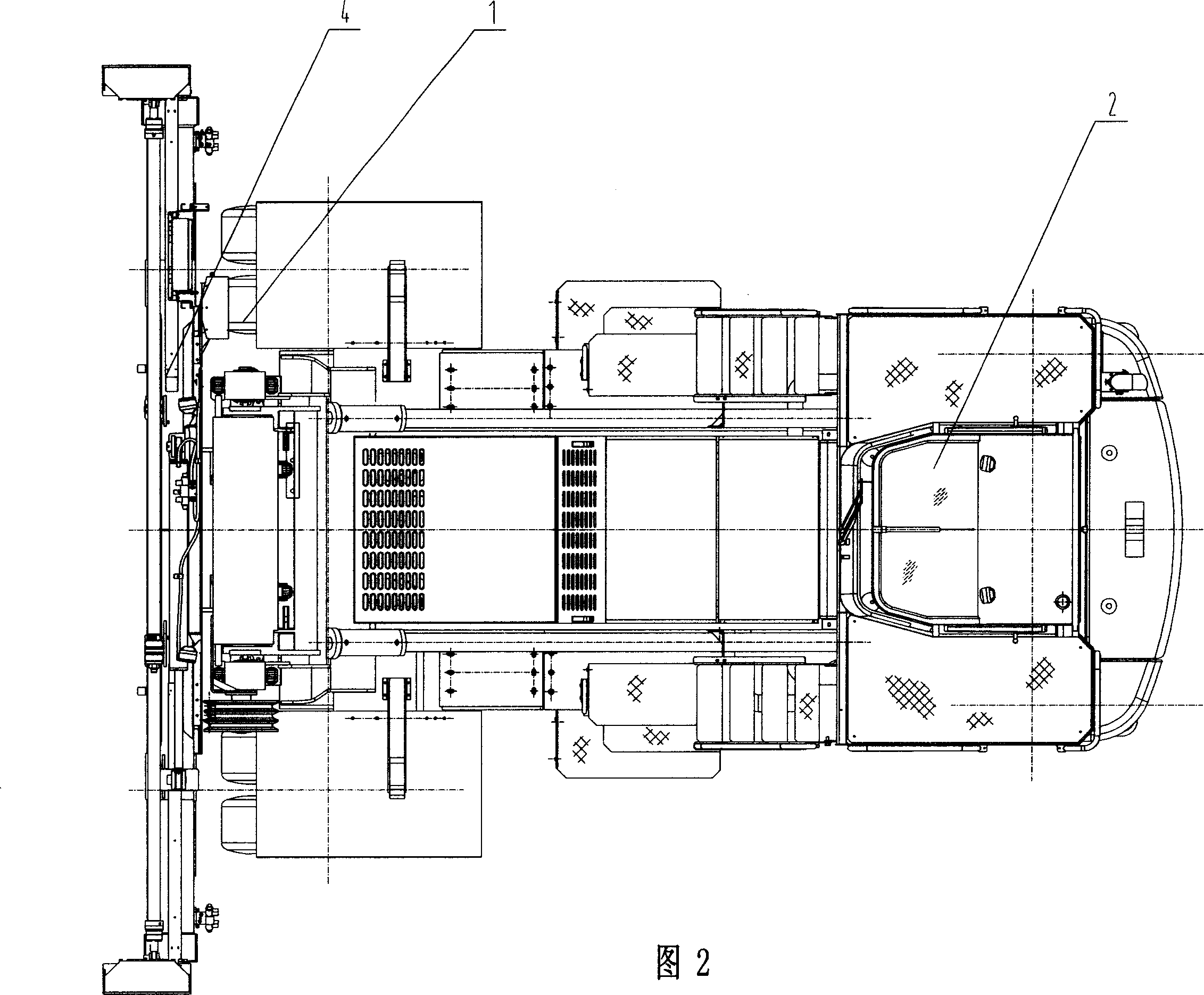

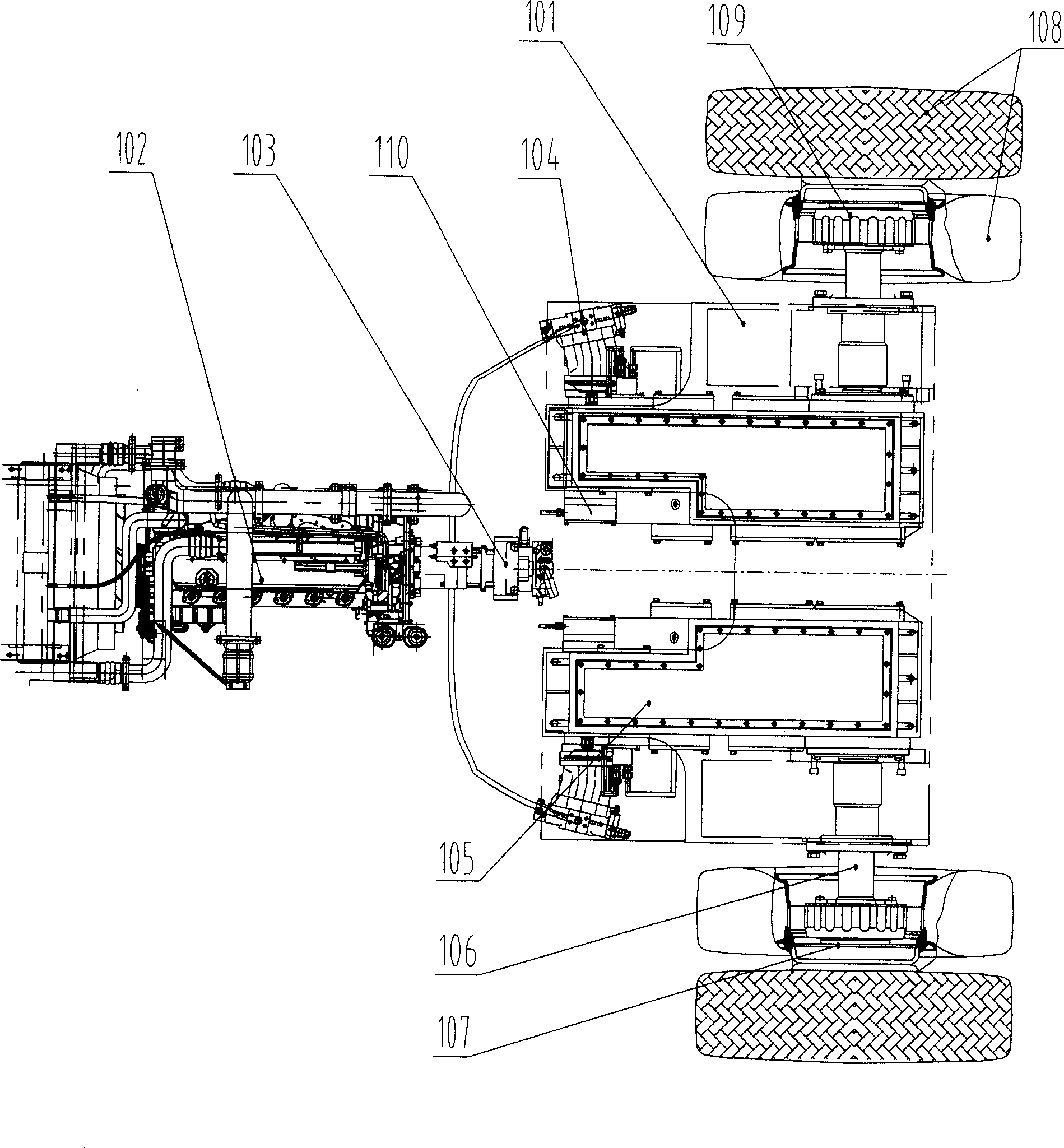

[0045] Figure 1, Figure 2 and image 3 As shown, the full hydraulic empty container stacker of the present invention comprises a traveling chassis 1, a driver's cab 2, a door frame 3 and a spreader 4, and the driver's cab 2 and the door frame 3 are installed on the walking chassis 1, and the spreader 4. Installed on the mast 3, the walking chassis 1 includes a chassis frame 101, an engine 102, a hydraulic pump 103, a hydraulic motor 104, a reducer 105, a half shaft 106, a wheel mechanism 107 and a tire assembly 108. The hydraulic pump 103 is connected to the output end of the engine 102. The hydraulic pump 103 is connected to two or more hydraulic motors 104 through pipelines. The output end of the hydraulic motor 104 is connected to the half shaft 106 through the reducer 105. The half shaft 106 passes The wheel edge mechanism 107 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com