Method of manufacturing a cooling plate and a cooling plate manufactured with this method

A cooling plate and plate body technology, which is applied in the field of manufacturing cooling plates, can solve the problems of difficult removal of casting sand, improper molding, and insufficient firmness of cooling pipes, and achieve reliable production, quality, economical savings, and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

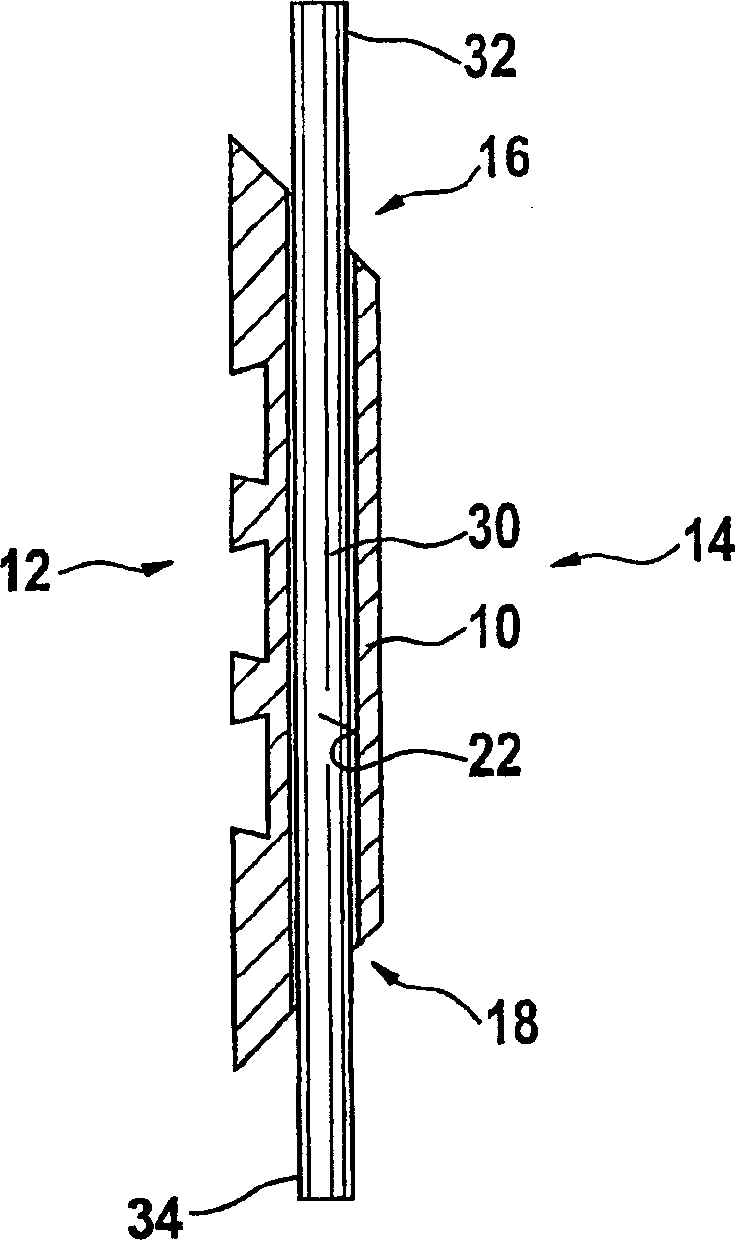

[0057] figure 1 Shown is a sheet metal body 10 according to the invention for producing cooling panels (also called stave walls) which are arranged inside the walls of a metallurgical furnace, for example a blast furnace. The plate body 10 has a front 12 , a back 14 and four peripheral surfaces. Two of the four peripheral surfaces are identified with reference numerals 16, 18, while the other two peripheral surfaces are in figure 1 is not visible in the cross-sectional view. The two peripheral surfaces 16 , 18 are inclined towards the rear side 14 of the plate body 10 . The front face 12 exposed inside the blast furnace is advantageously provided with grooves 20 which increase the cooling surface and improve the adhesion of the refractory lining. The reference numeral 22 designates a straight cylindrical channel 22 which penetrates the sheet metal body 10 below the front face 12 to form openings 24 , 26 on the peripheral faces 16 and 18 . The cross-section of the channel i...

example

[0063] Tube diameter: 69,9-70,1mm (at 20°C)

[0064] Channel diameter: 70,3-70,8mm (at 20°C)

[0065] Rolling the plate by 1 mm is sufficient to achieve a press fit of the tube 30 in the channel 22 . The cross-section of the tube 30 becomes slightly oval.

[0066] Since there is a certain upper limit to the extent to which the entire plate body 10 can be rolled, additional steps may be applied as pre- or post-processing in order to support the press fit obtained by rolling the plate body 10 . A number of such additional steps are described below.

[0067] In the first additional step, as in Figure 6 As shown, channels 22 and tubes 30 are dimensioned in cross-section such that both plate 10 and tubes 30 have a radial clearance of tubes 30 in channels 22 at ambient temperature (ie, a positive tolerance). After the tube 30 is inserted into the channel 22 of the plate body 10 , the conical expansion head 40 is pulled through the tube 30 by the hydraulic cylinder 42 . This ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com