Pyroelectric ceramic materials and gel casting method thereof

A technology of gel injection molding and pyroelectric ceramics, which is applied to other household appliances, clay products, household appliances, etc., and can solve the problems of rough surface, oxygen resistance effect, increased production cycle and manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] 1) Mix the raw materials according to the following proportions. Ball milling is to add deionized water and powder to mix. The ball milling time is 4 hours. The drying temperature is 100°C. The drying time is 12 hours. The sieve is 60 mesh. 200°C / h, and the pre-burning temperature is 800°C. The ratio of each raw material is: Pb 3 o 4 : 192.45, La 2 o 3 : 16.29, CaCO 3 : 10.11, TiO 2 : 78.29.

[0028] 2) Dissolve ethyl silicate in a mixture of deionized water and alcohol, then add hydrochloric acid, mix and stir, and prepare a hydrolyzate, whose volume ratio V 硅酸乙脂 :V 去离子水 :V 酒精 :V 盐酸 =1:0.4:0.2:0.004;

[0029] 3) Mix and stir the pyroelectric ceramic powder and hydrolyzate evenly to make a slurry, whose volume ratio V PLCT :V 水解液 =4:5;

[0030] 4) The slurry is defoamed by vacuum and poured in the mould;

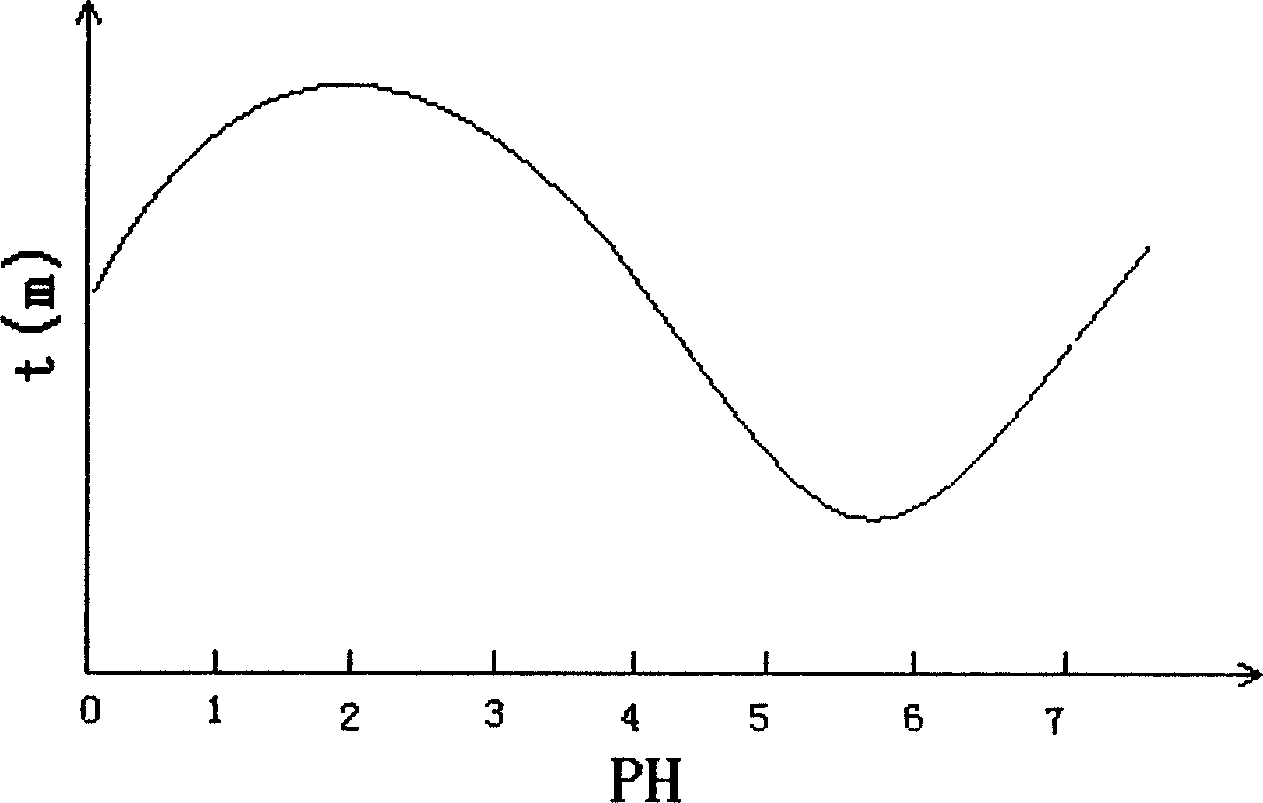

[0031] 5) Adjust the pH value of the slurry to 2 by dropping hydrochloric acid to make the slurry solidify rapidly, and then dry it at 25°C for 2 days t...

example 2-6

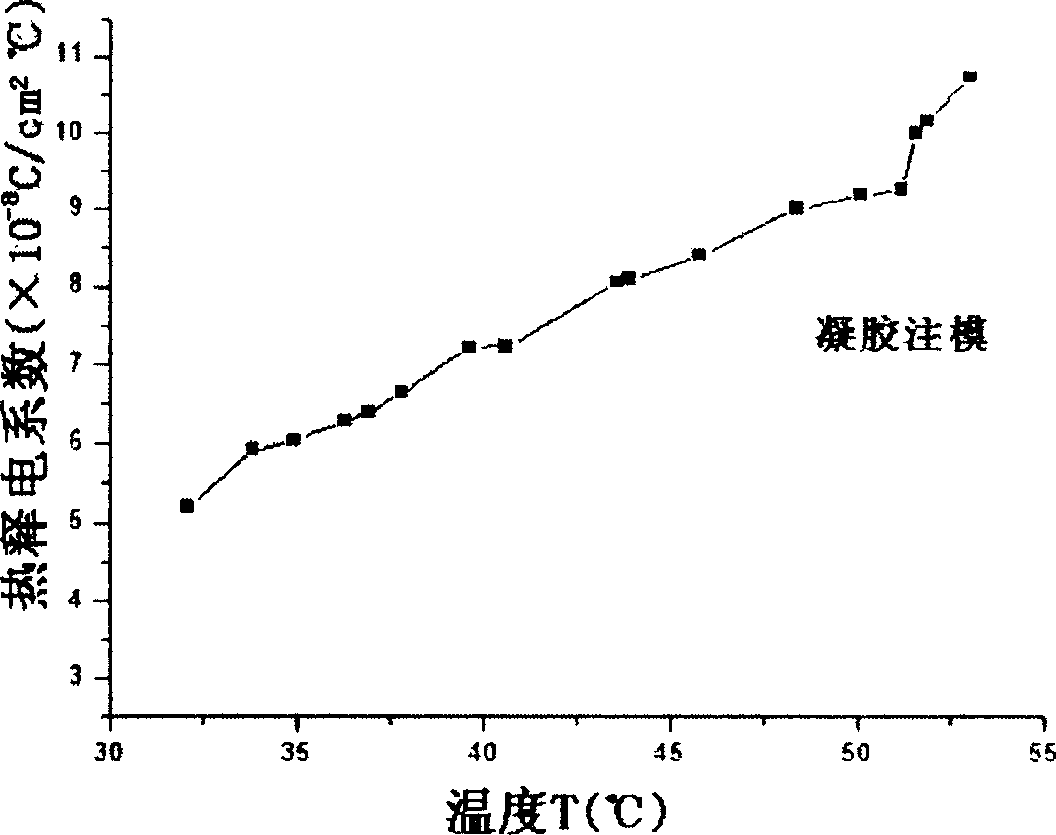

[0034] According to the steps described in Example 1, the raw materials were processed using the process parameters in Table 1, and the electrical properties of the obtained ceramic materials are shown in Table 2.

[0035]

[0036] example

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com