Installation work management method, installation machine and preparation support method, installation assembly line

A technology for job management and installation machine, which is applied in the direction of assembling printed circuits, electrical components, and electrical components with electrical components, which can solve problems such as component shortages and errors, and inability to obtain production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

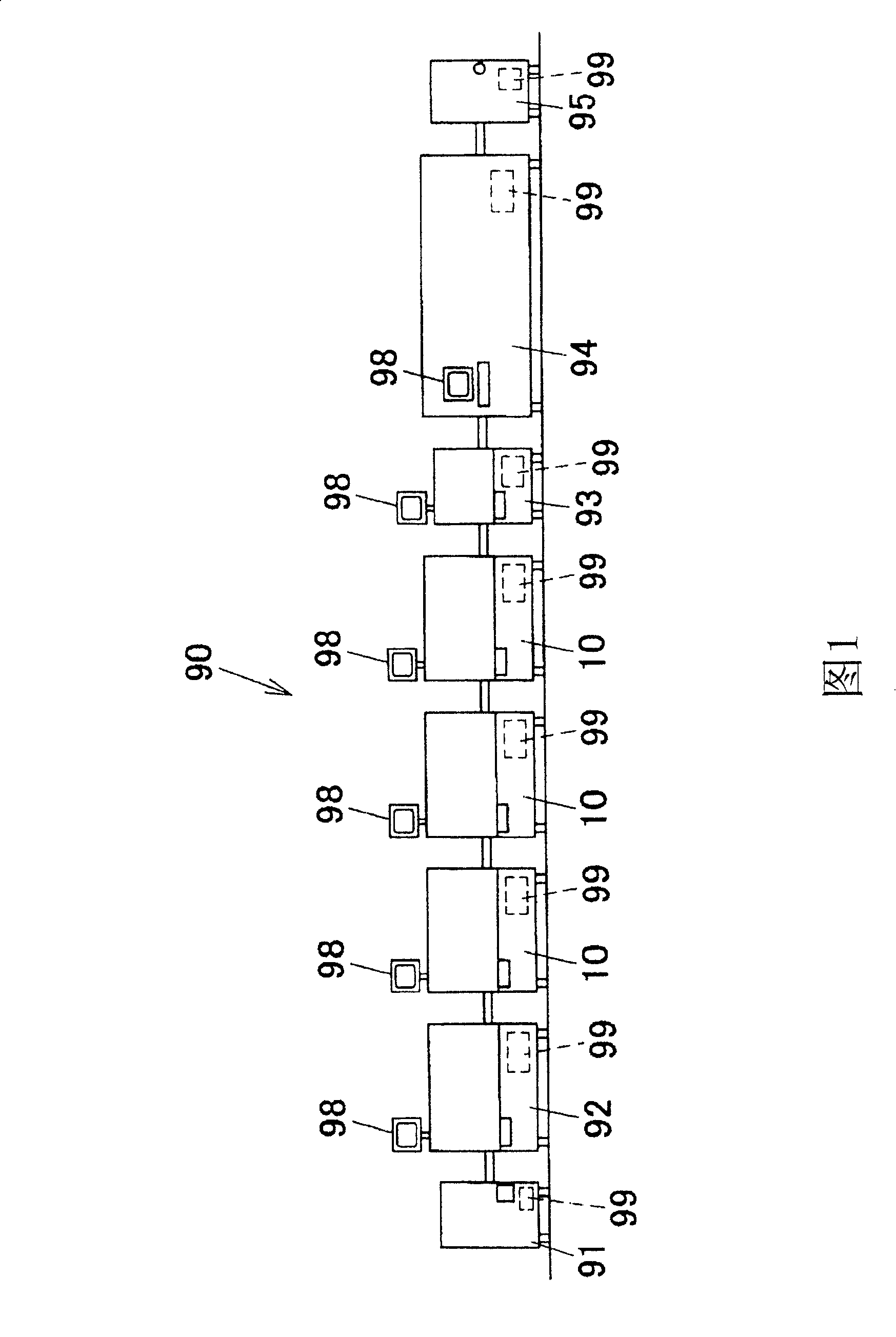

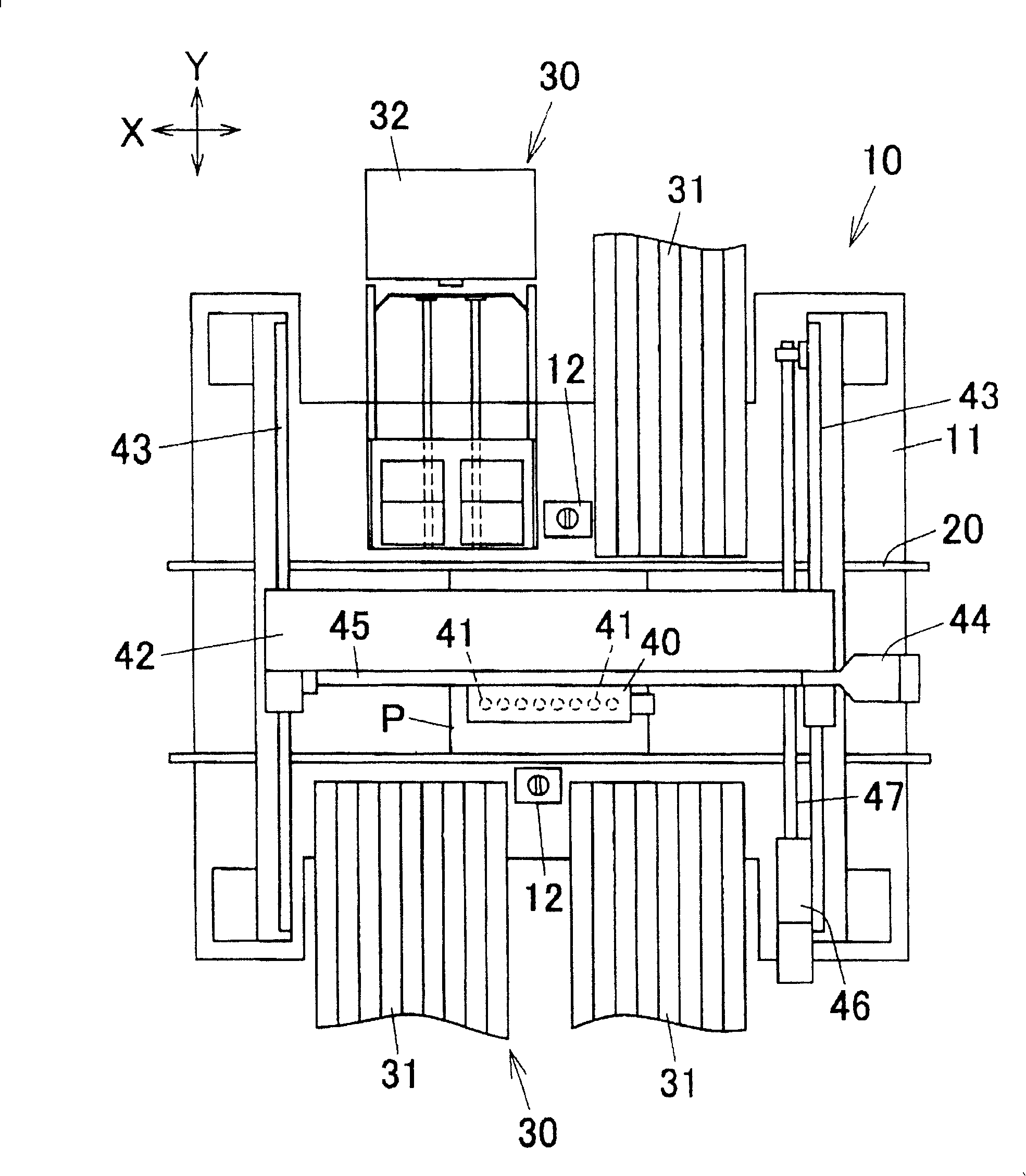

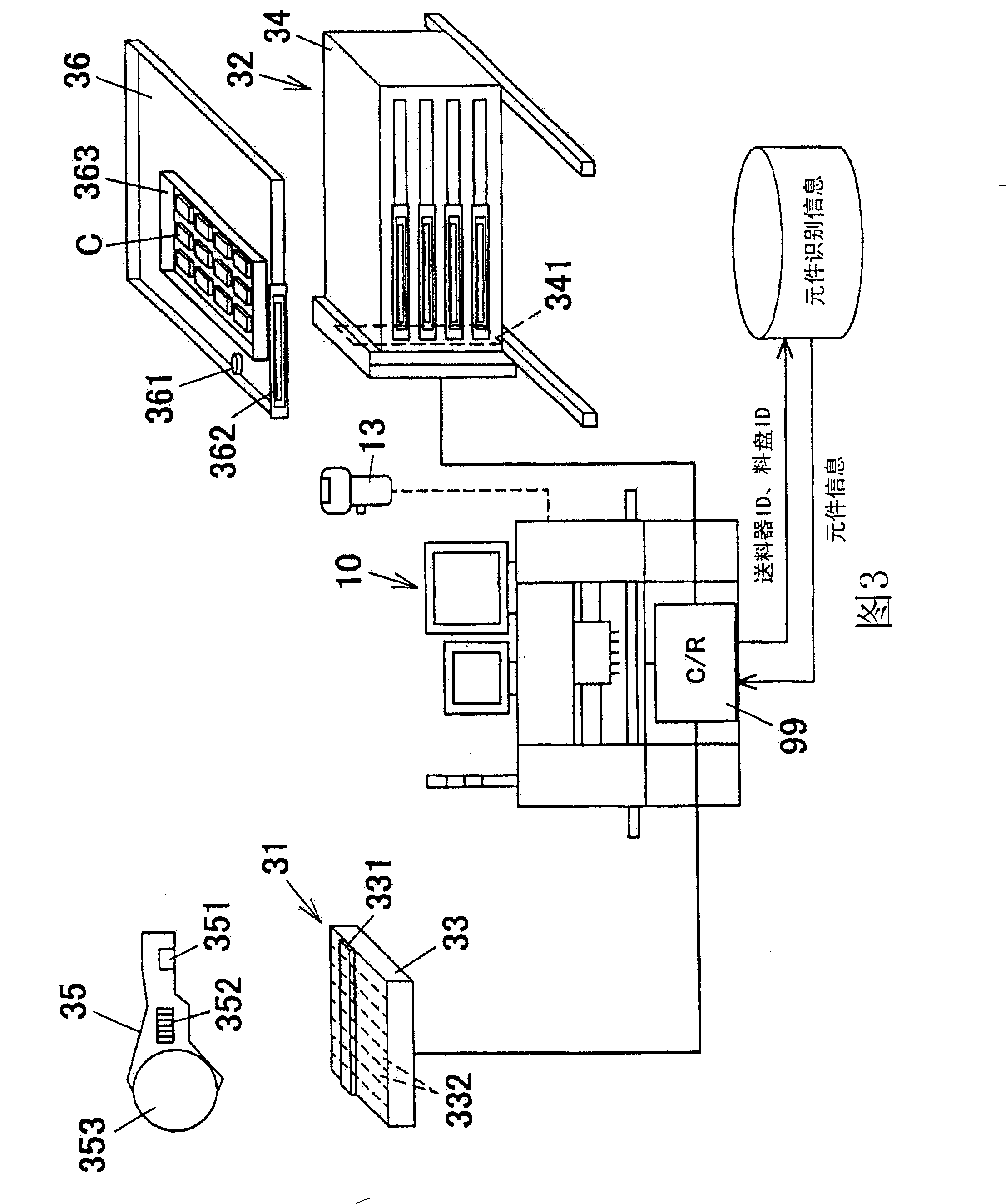

[0099] Fig. 1 is a schematic side view of an installation line applicable to the present invention. As shown in Fig. 1, the installation line 90 includes a board loading machine 91, a printing press 92, multiple (3) mounting machines 10..., an inspection machine 93, and a reflow furnace from the upstream side to the downstream side of the production line. 94 and substrate unloading machine 95 and other equipment.

[0100] The substrate loading machine 91 is a device that stores a plurality of substrates and sequentially loads the substrates to the printer 92. The printer 92 is a device that applies the solder paste by printing in the substrate processing area that is carried in. The mounting machine 10... is a device that mounts electronic components on a predetermined position on a substrate. The inspection machine 93 is a device that inspects the mounting state of electronic components mounted on the substrate. The reflow furnace 94 is a device for soldering the substrate an...

no. 2 Embodiment approach

[0197] Next, a second embodiment according to the present invention will be explained. The basic structure of the mounting line applied to the second embodiment, the mounting machine included in the mounting line, and the functions of the mounting machine component supply unit are the same as those of the first embodiment (FIGS. 1 to 3 ), and therefore the description is omitted. Only the differences are explained in detail below.

[0198] In the mounting line 90 of the second embodiment, the mounting work of various components on the substrate to be produced is allocated to the component supply device mounted on any mounting machine of the mounting line 90. Then, for components that are not installed on any mounting machine of the installation line 90 among the required components, the operator is notified and prompted to install it on any mounting machine of the installation line 90.

[0199] According to this method of operation, if the component supply device for supplying req...

no. 3 Embodiment approach

[0256] Next, a third embodiment of the present invention will be explained. The basic structure of the mounting line applicable to the third embodiment, the mounting machine included in the mounting line, and the functions of the mounting machine component supply unit are the same as those of the first embodiment (FIGS. 1 to 3 ), so the description is omitted. In the following, only the differences will be described in detail.

[0257] The installation line 90 of the third embodiment is basically the same as that of the first embodiment. According to the disclosed optimization method, the installation machine 10 on which the installation work is allocated is determined, and the sequence of the initial production process is made to perform each installation. The sequence of the mounting work allocated on the mounting machine, based on this, corresponds to the configuration of the component supply device currently installed on any mounting machine of the mounting line 90, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com