Bell-jar funnel cap for fluidized bed

A fluidized bed and bell hood technology is applied in the field of structural design of air caps in air distribution devices, which can solve the problems of wear of air distribution holes, increased power consumption of fans, and increased power consumption of power plants, and achieves reduction of resistance coefficient, distribution of Even wind and less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure and principle of the present invention will be further explained below in conjunction with the drawings:

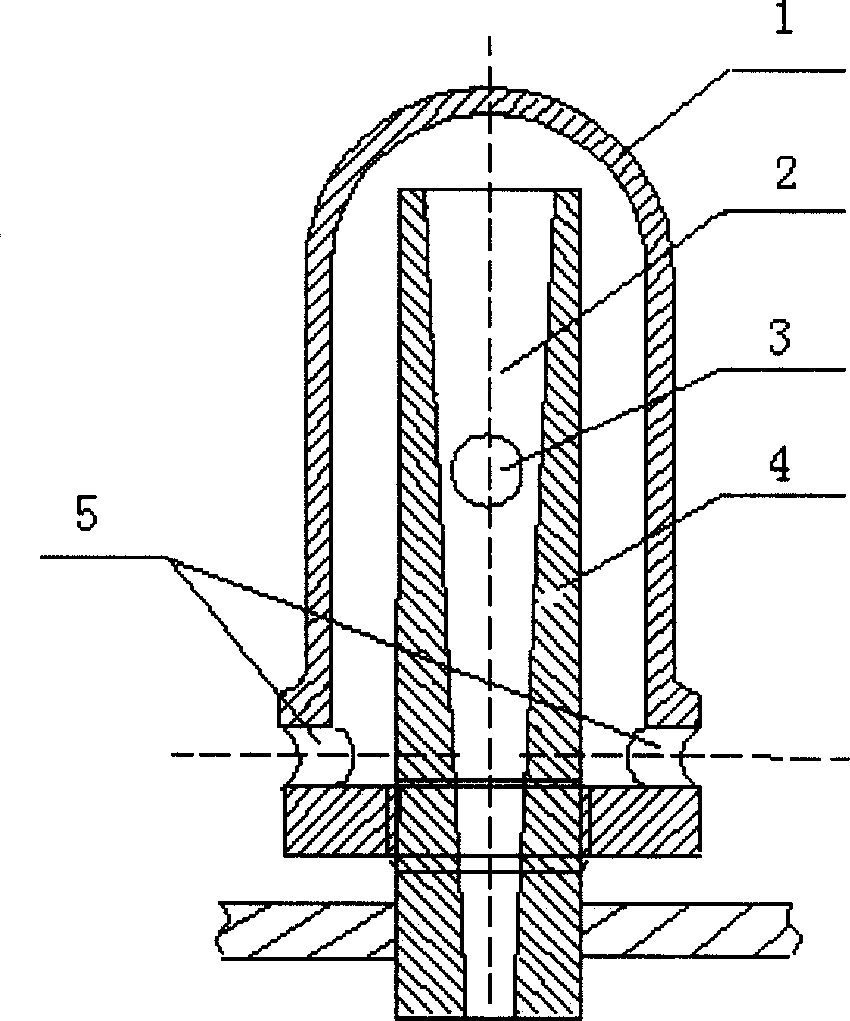

[0016] figure 1 The structure diagram of the improved bell-type hood provided by the present invention. The hood includes a vent pipe 4, an outer cover 1 arranged on the outside of the vent pipe, and air distribution holes 5 evenly arranged in the lower part of the outer cover, arranged inside the vent pipe The cone-shaped airflow channel 2 and the float 3 arranged in the cone-shaped airflow channel; the outside of the lower middle part of the ventilation pipe and the inner part of the lower part of the outer cover are connected by threads.

[0017] Before the boiler is started, the float falls on the lower part of the ventilation pipe under the action of gravity; as the primary air volume increases, the air flow starts to lift the float upwards and reaches a balance at a certain position. The air flow flows out from the gap between the float 3 and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com