Cable work well and construction method thereof

A construction method and technology for working wells, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve problems such as high requirements for lifting equipment, high lifting difficulty, and limited choice of working well shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and embodiments.

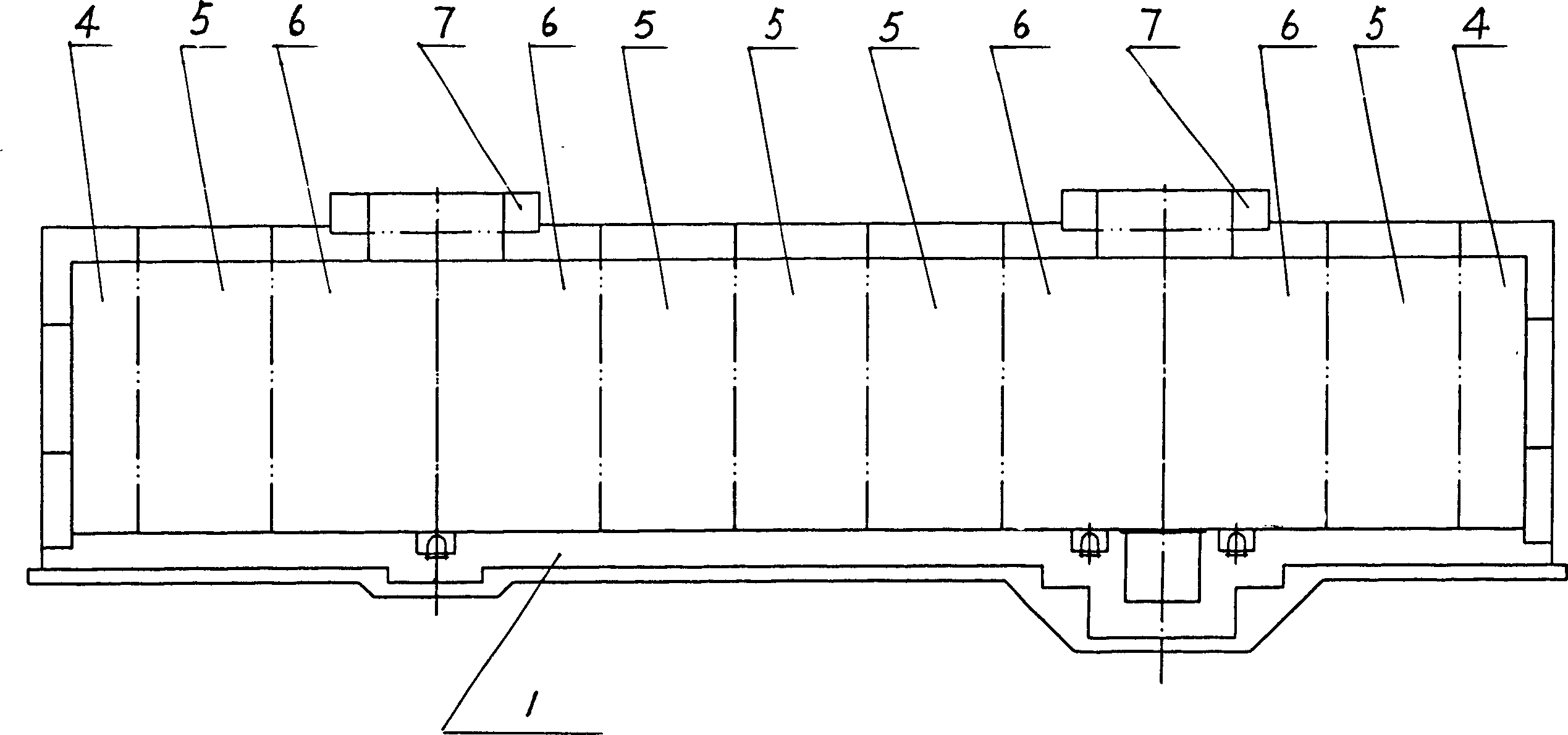

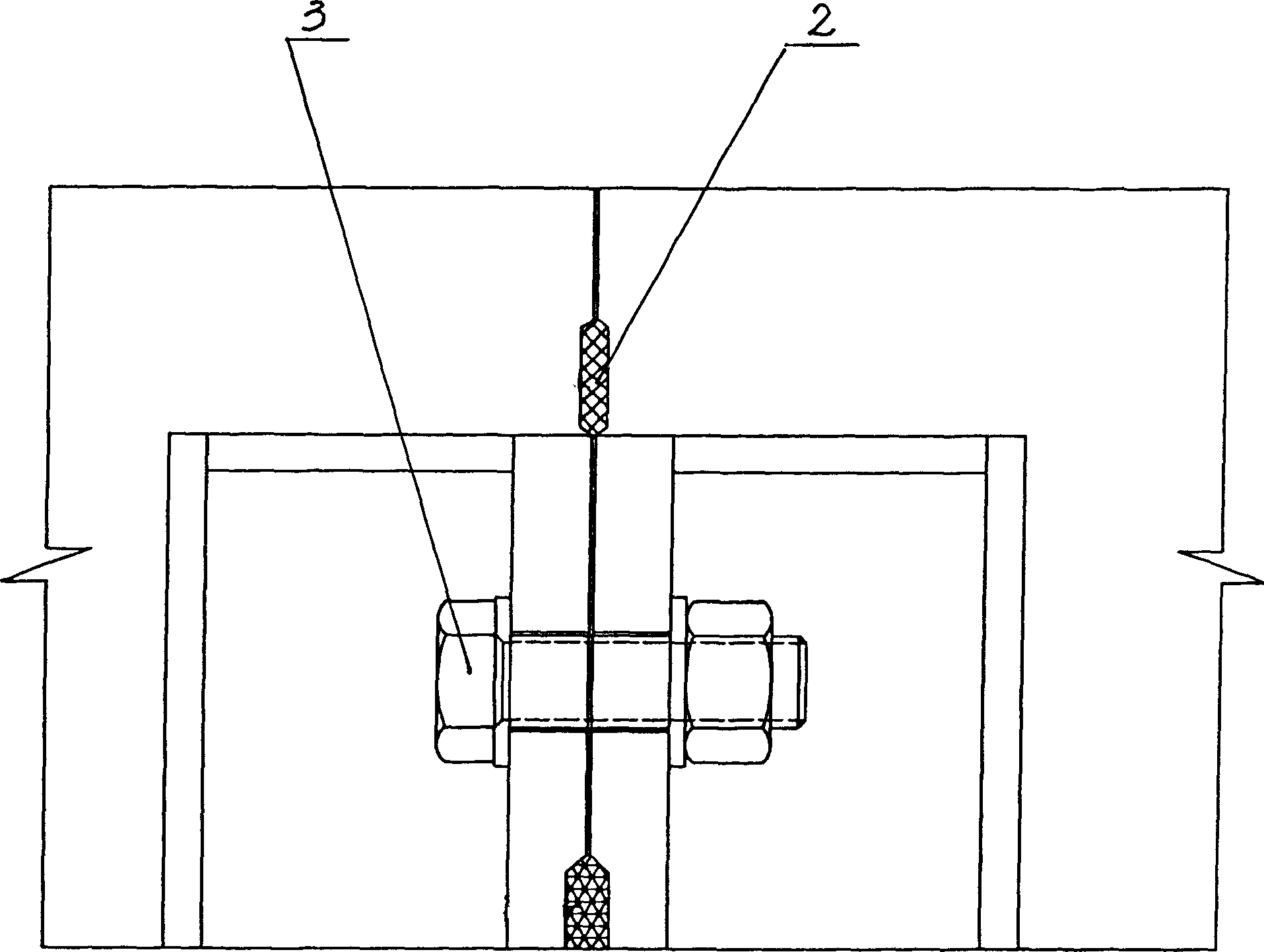

[0023] like figure 1 , 2 As shown, the cable work well includes a base 1, a well body, a seal 2 and a bolt group 3. The base 1 is a cast-in-place reinforced concrete base, and the well body consists of two D-type blocks 4 and five B-type blocks 5. , four TD blocks 6 and two TK blocks 7, a total of thirteen prefabricated building blocks. like figure 2 As shown, the joints between the prefabricated building blocks are cushioned with seals, and the prefabricated building blocks are connected by bolt groups. There is also a seal at the seam between the prefabricated member and the base.

[0024] This embodiment is constructed according to the following steps and methods:

[0025] i. Construction of foundation pit enclosure for cable work wells;

[0026] ii. Foundation pit excavation;

[0027] iii. C10 plain concrete cushion pouring;

[0028] iv. Rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com