Splicing device, yarn splicing method and joint

A technology of splicing device and yarn, applied in the direction of piecing device, spinning machine, transportation and packaging, etc., can solve problems such as appearance deterioration, and achieve the effect of reducing manufacturing cost and simplifying shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

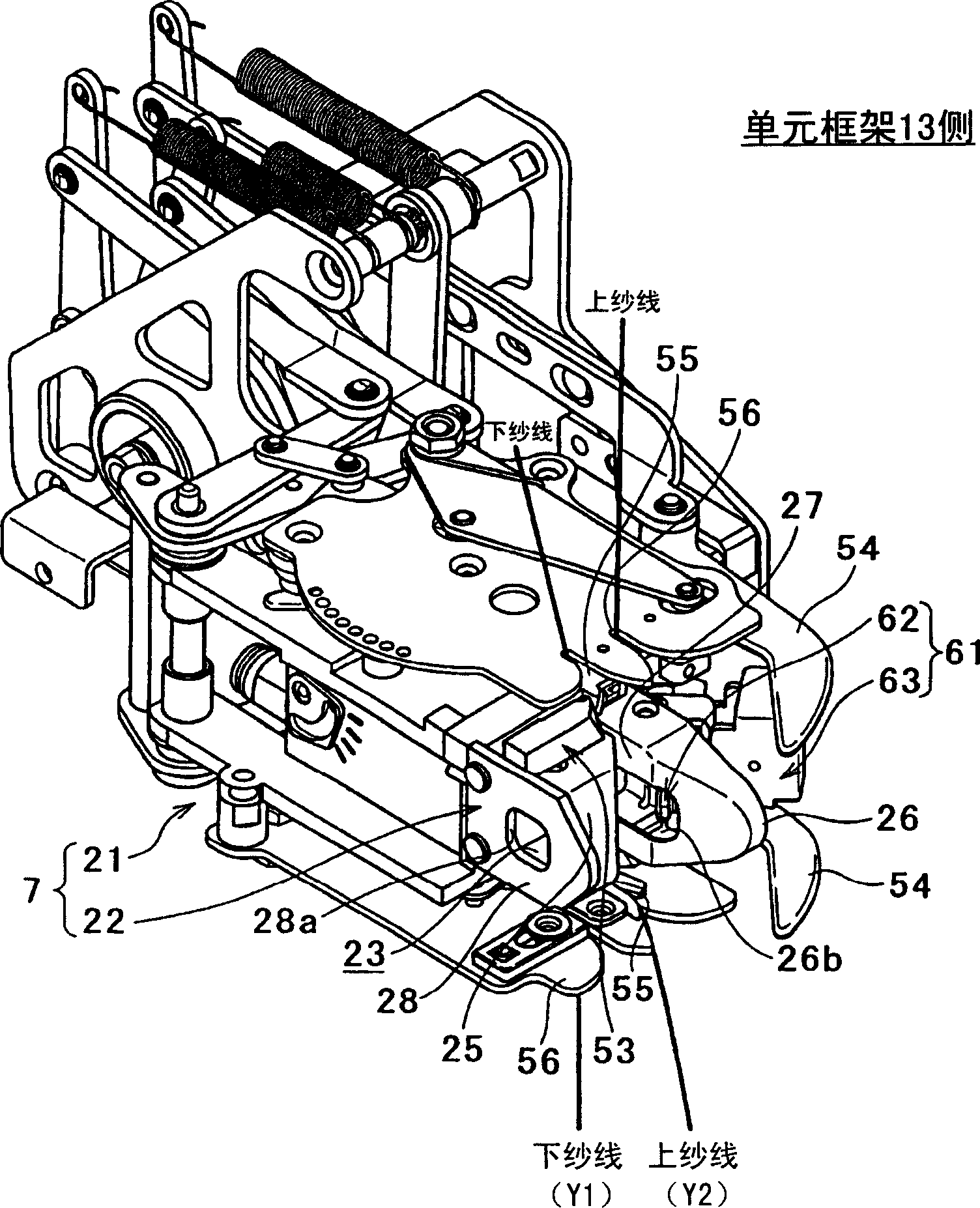

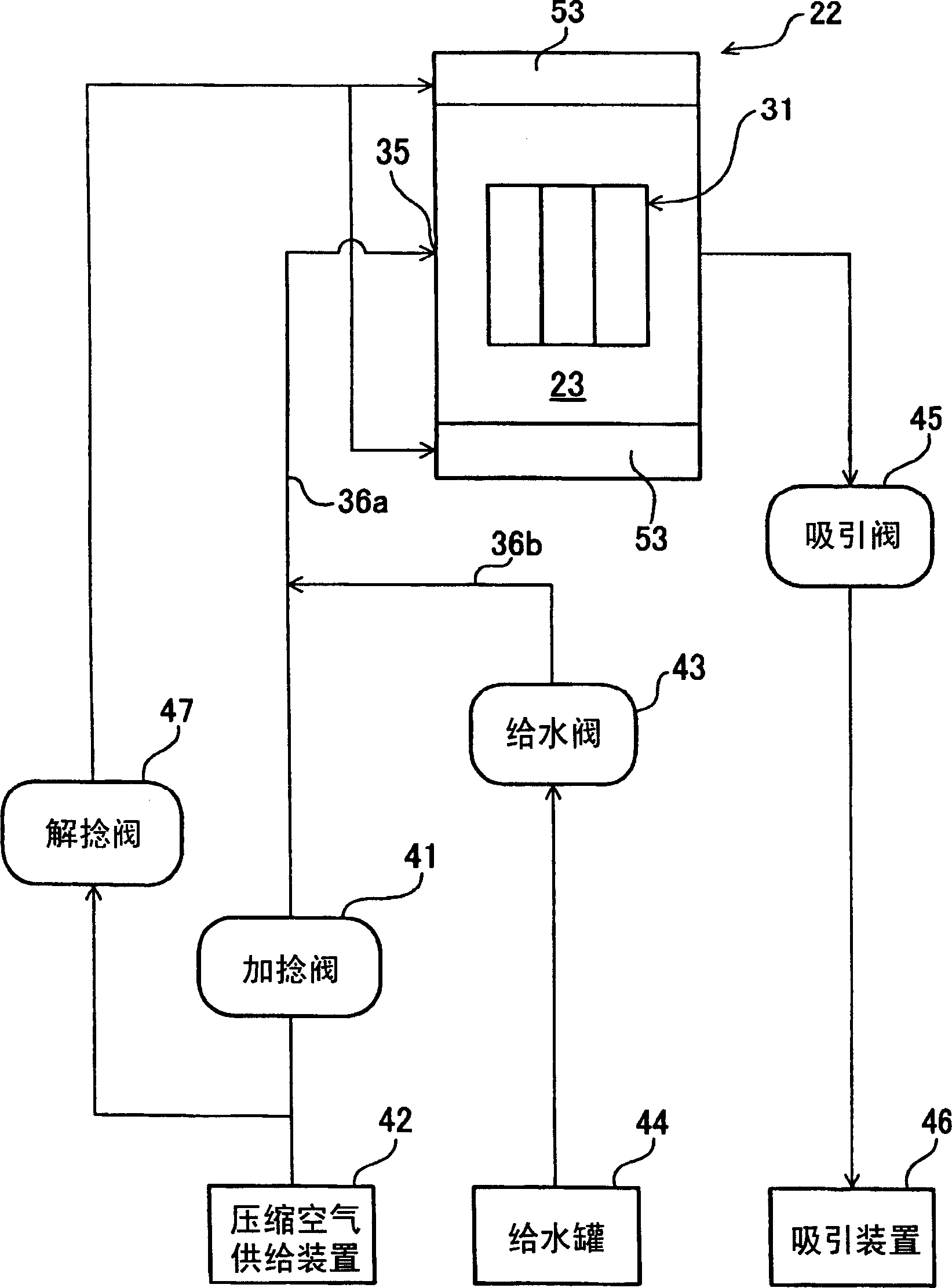

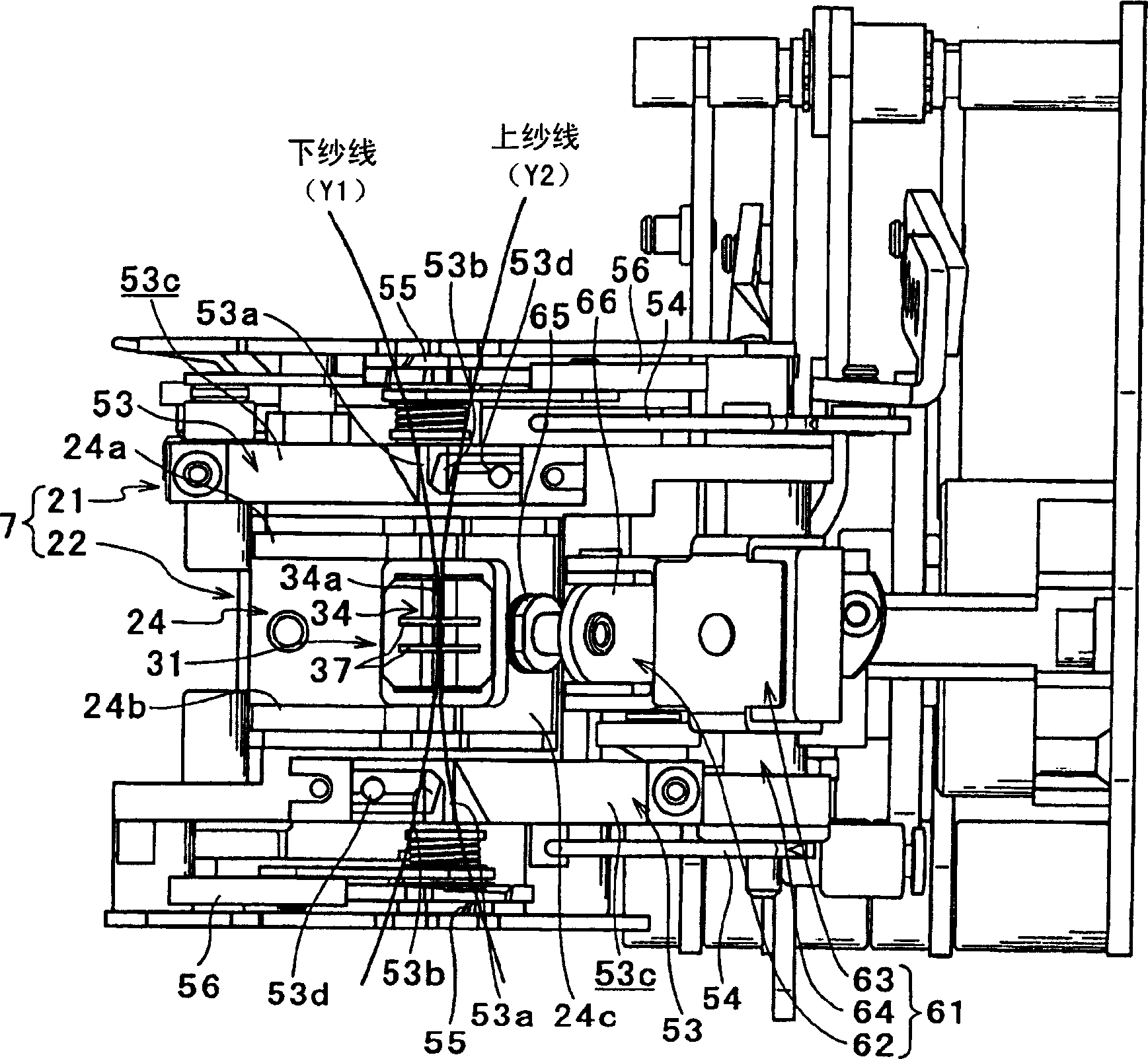

[0047] Next, an embodiment of the present invention will be described with reference to the drawings. First, see Figure 11 Describes an automatic winder incorporating a splicing device.

[0048] Figure 11 A schematic front view of an automatic winder is shown. The yarn winding unit 1 of the automatic winder winds the spun yarn Y (flax yarn in this embodiment) unwound and supplied from the yarn supply bobbin B under the traversing action of the traversing drum 3 . A take-up bobbin P having a predetermined length and a predetermined shape is formed on the take-up bobbin tube Bf. exist Figure 11 In, only one yarn winding unit 1 is shown, however, a plurality of such yarn winding units 1 are installed side by side, and an unshown frame control device is arranged at one end of the installation direction, in this In this case, a yarn winder (automatic winder) has been constructed.

[0049] In the yarn winding unit 1, a unit frame 13 is provided on a horizontal side of the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com