Electrochemical gas sensor

A gas sensor, electrochemical technology, applied in scientific instruments, instruments, material analysis through electromagnetic means, etc., can solve the problems of increased cost and complicated structure, and achieve the effect of ensuring liquid tightness and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, the specific content of the present invention will be described based on the illustrated embodiment.

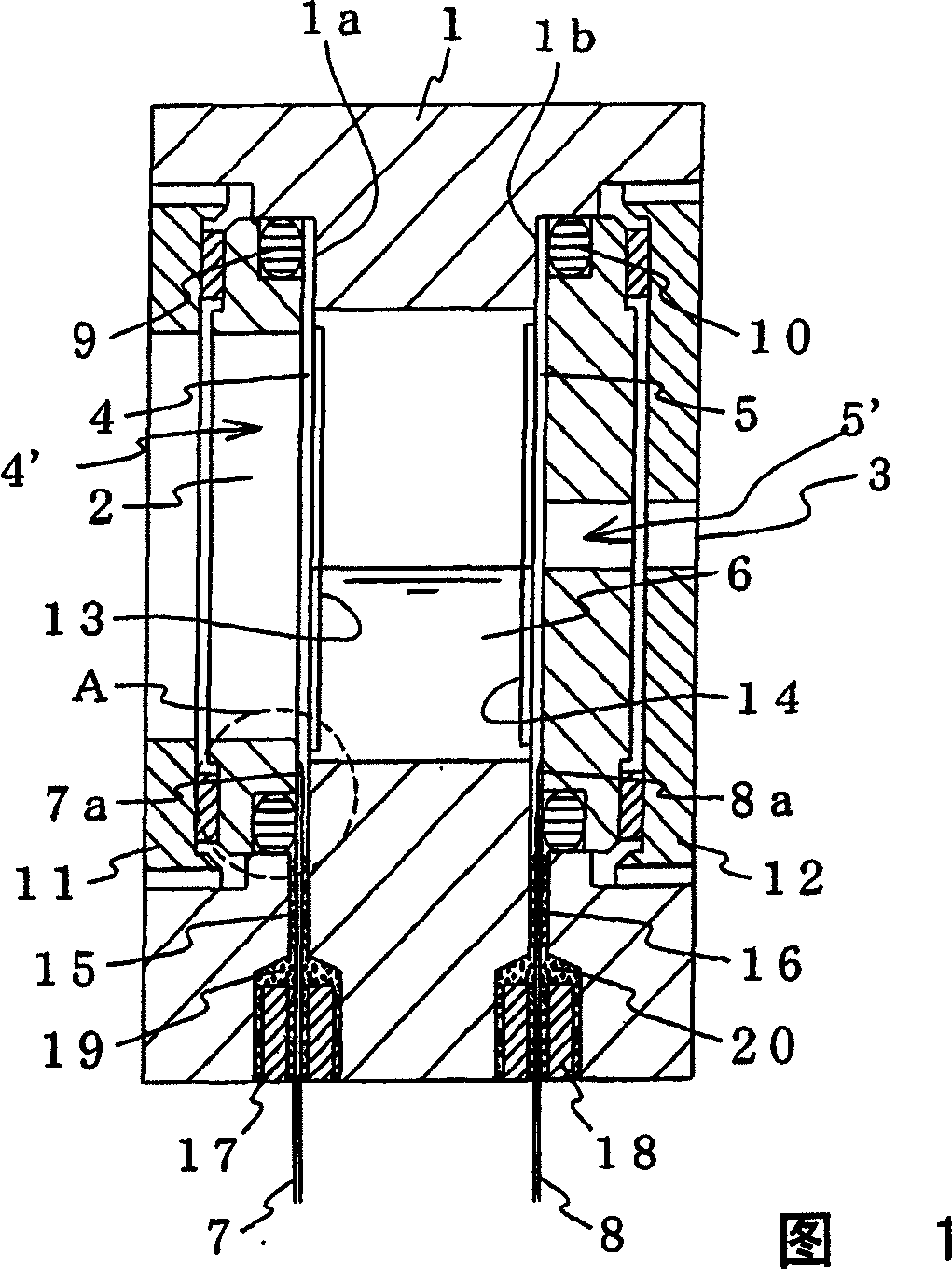

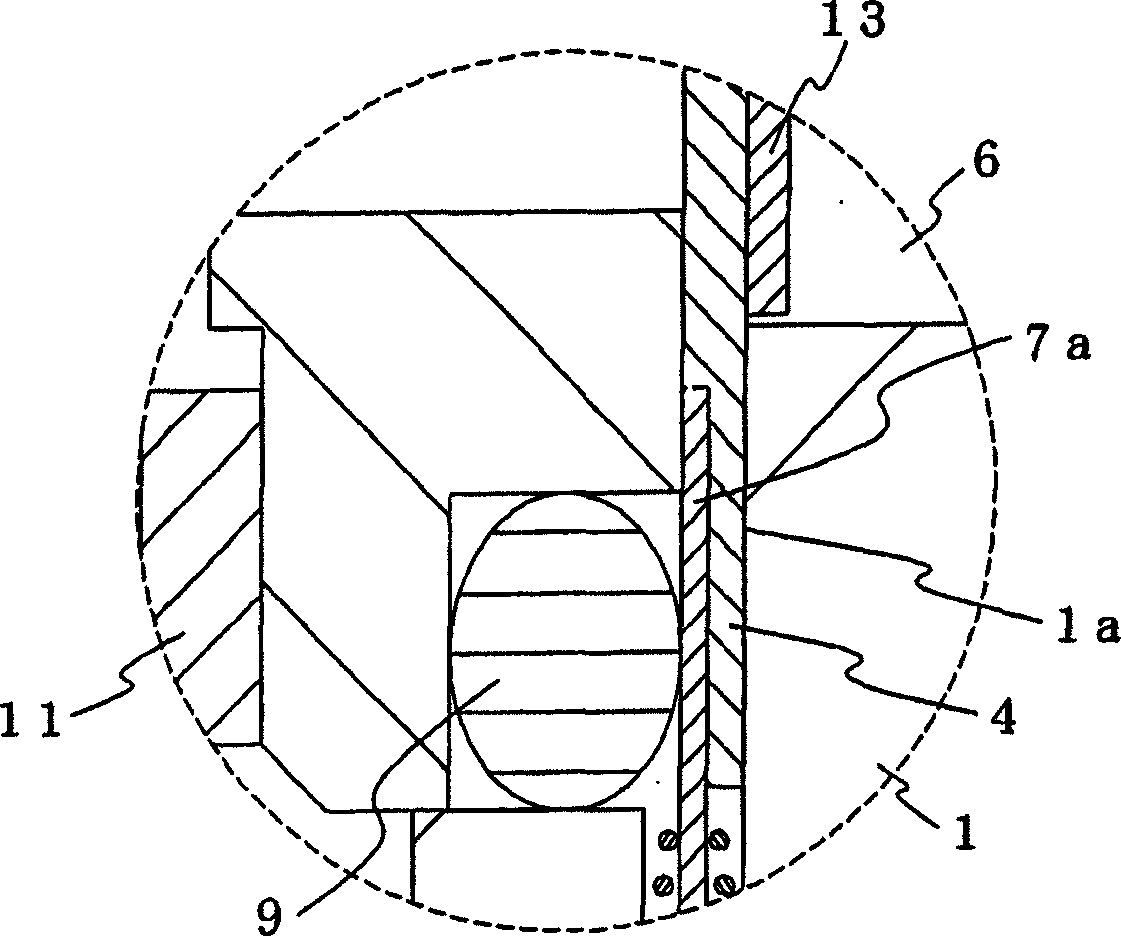

[0041] Fig. 1 has shown an embodiment of the electrochemical type gas sensor of the present invention, on the opposite wall of the container 1 that is stored with the electrolytic solution 6 that is made of sulfuric acid, is formed with the window 2,3 that is made of through hole, working electrode Part 4' (gas-permeable membrane 4 and electrode catalytic layer 13) and counter electrode part 5' (gas-permeable membrane 5 and electrode 14) are tensioned and arranged on windows 2 and 3 respectively, and on working electrode part 4' and counter electrode part 5' Lead parts 7, 8 are arranged on the surface opposite to the electrolytic solution 6 respectively, and the lead parts 7, 8 are fixed by the fixing rings 11, 12, between the outer sides of the lead parts 7, 8 and the fixing rings 11, 12 Ring packings 9, 10 are provided.

[0042] In addition, since the sulfuric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com