Biosensor and method for preparation thereof

A biosensor and manufacturing method technology, applied in the field of biosensors, can solve problems such as complicated operation, time-consuming, and reduced measurement accuracy, and achieve the effects of eliminating measurement errors, preventing electrodes from rusting, and excellent measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

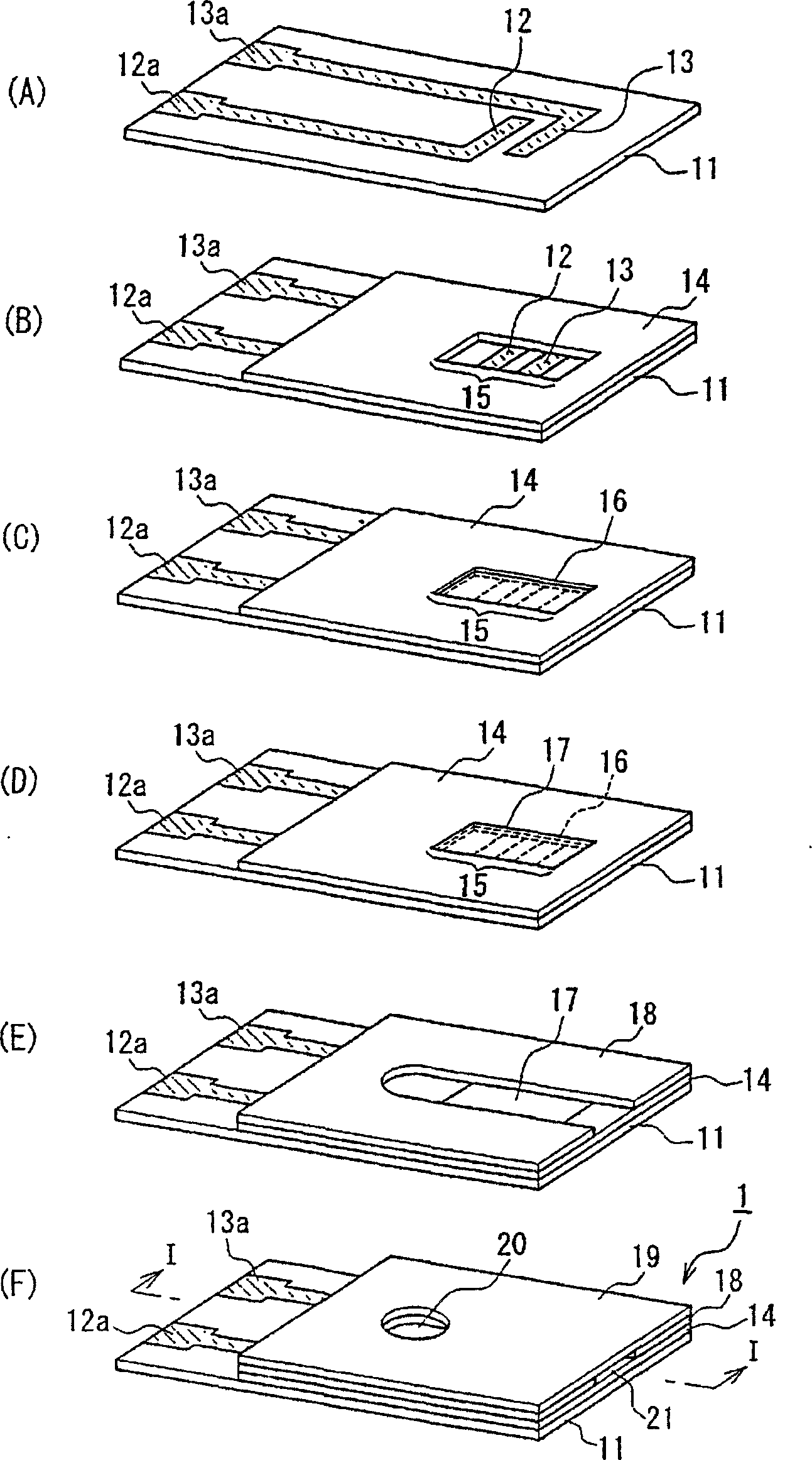

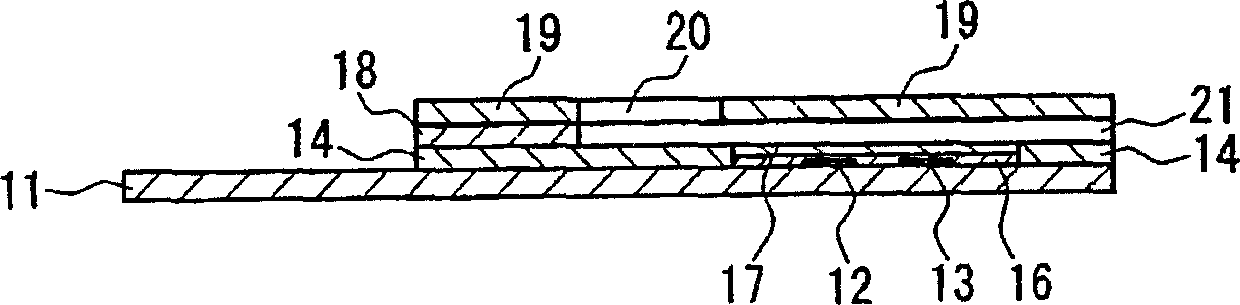

[0070] An example of the first biosensor manufacturing method of the present invention is as follows figure 1 and figure 2 based on the description. figure 1 (A) to (F) are perspective views showing a series of steps of manufacturing the biosensor. figure 2 for the above figure 1 (F) I-I cross-sectional view of the shown biosensor. figure 1 (A)~(F) and figure 2 with the same symbol in the same position.

[0071] Such as figure 1 (F) and figure 2 As shown, this biosensor 1 is provided with a substrate 11, an electrode system composed of a working electrode 12 having a lead portion 12a and a counter electrode 13 having a lead portion 13a, an insulating layer 14, a layer containing a medium, a layered inorganic compound, and a surfactant. An inorganic gel layer (anti-oxidation layer) 16 , an enzyme reagent layer 17 containing oxidoreductase, a separator 18 having an opening, and a cover 19 having a through hole 20 . Such as figure 1 As shown in (B), one end portion o...

Embodiment 1

[0130] As shown below, making the same as above figure 1 (F) Glucose sensor with the same structure.

[0131] First, a PET substrate (50 mm in length, 6 mm in width, and 250 μm in thickness) is prepared as the insulating substrate 11 of the glucose sensor, and the working electrode 12 and the counter electrode each having a lead portion are formed on one surface by screen printing. 13 carbon electrode system.

[0132] Next, an insulating layer 14 is formed on the above-mentioned electrodes as follows. First, the insulating resin polyester was dissolved in the solvent carbityl acetate so as to have a concentration of 75% by weight to prepare an insulating paste, which was screen-printed on the above-mentioned electrodes. The printing conditions are 300 mesh screen, rubber roller pressure 40kg, and the printing volume is per 1cm 2 The electrode area is 0.002mL. Screen printing is not performed on the detection part 15 and the lead parts 12a and 13a. Then, insulating layer 1...

Embodiment 2

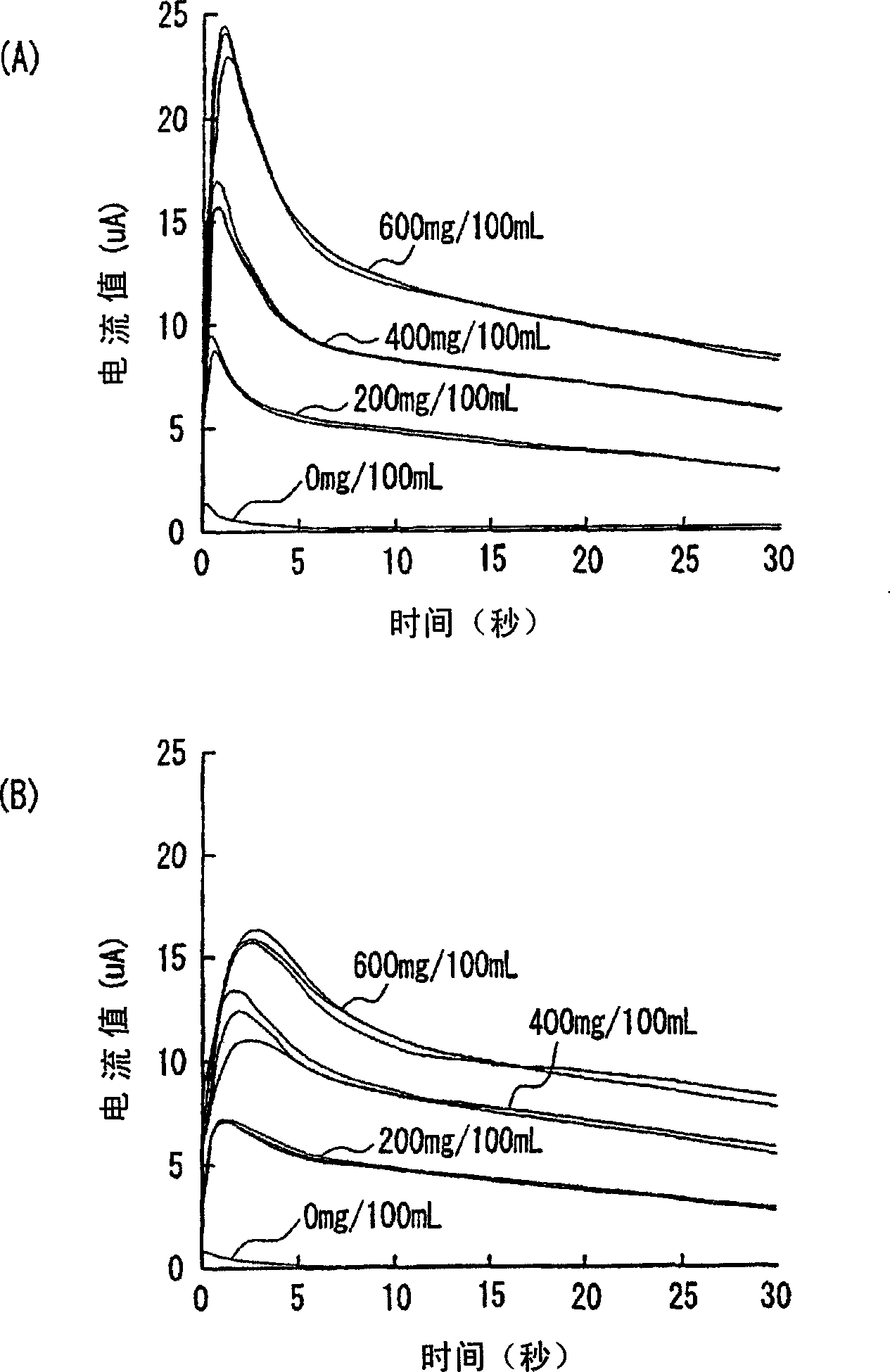

[0143] In this example, the glucose sensor produced in the above-mentioned Example 1 was used to measure the change with time of the response current corresponding to the glucose concentration.

[0144] As a liquid sample, human whole blood was used. First, the whole blood after blood collection was left at 37° C. for about one day, and the glucose concentration was adjusted to 0 mg / 100 mL. Then, glucose was added thereto to prepare samples of various glucose concentrations (approximately 200, 400, and 600 mg / 100 mL). Glucose-free whole blood was adjusted to a glucose concentration of 0 mg / 100 mL. Then, as Example 2, a voltage of 200 mV was applied to the above-mentioned glucose sensor 1 , and then the sample was dropped on the sample supply part 21 , and the time course of the response current 5 seconds after the drop was measured. As Comparative Example 2, the glucose sensor of Comparative Example 1 was measured in the same manner. Each of Examples and Comparative Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com