Temperature controlled floorboards, and ground temperature control system for the floorboards

A floor and floor layer technology, applied in heating systems, hot water central heating systems, applications, etc., can solve the problems of low heat dissipation efficiency, maintenance, failure, etc., and achieve the effects of low manufacturing cost, simple and convenient maintenance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The temperature control floor of the present invention and the ground temperature control system formed by the temperature control floor will be described in detail below with reference to the accompanying drawings and embodiments.

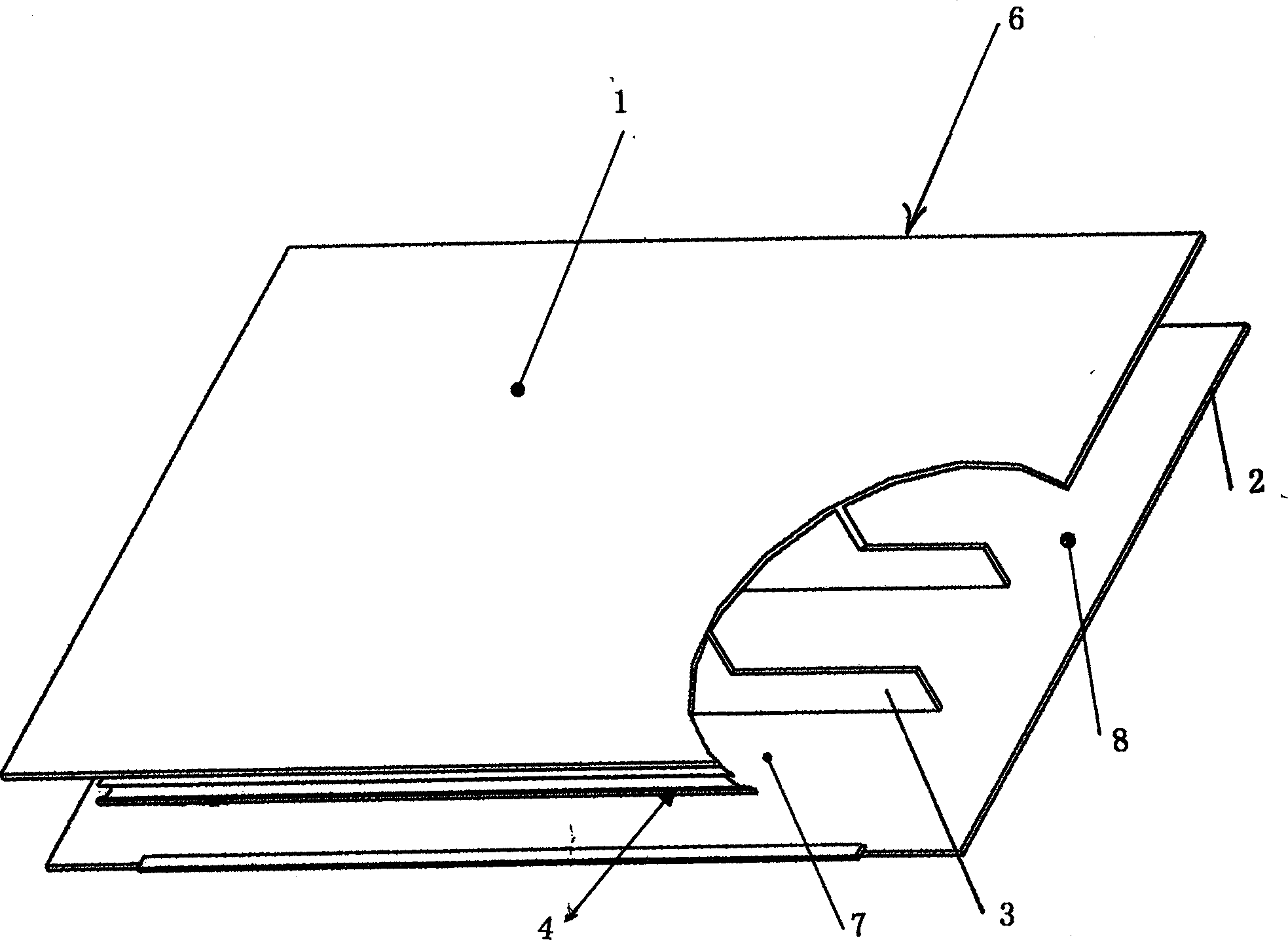

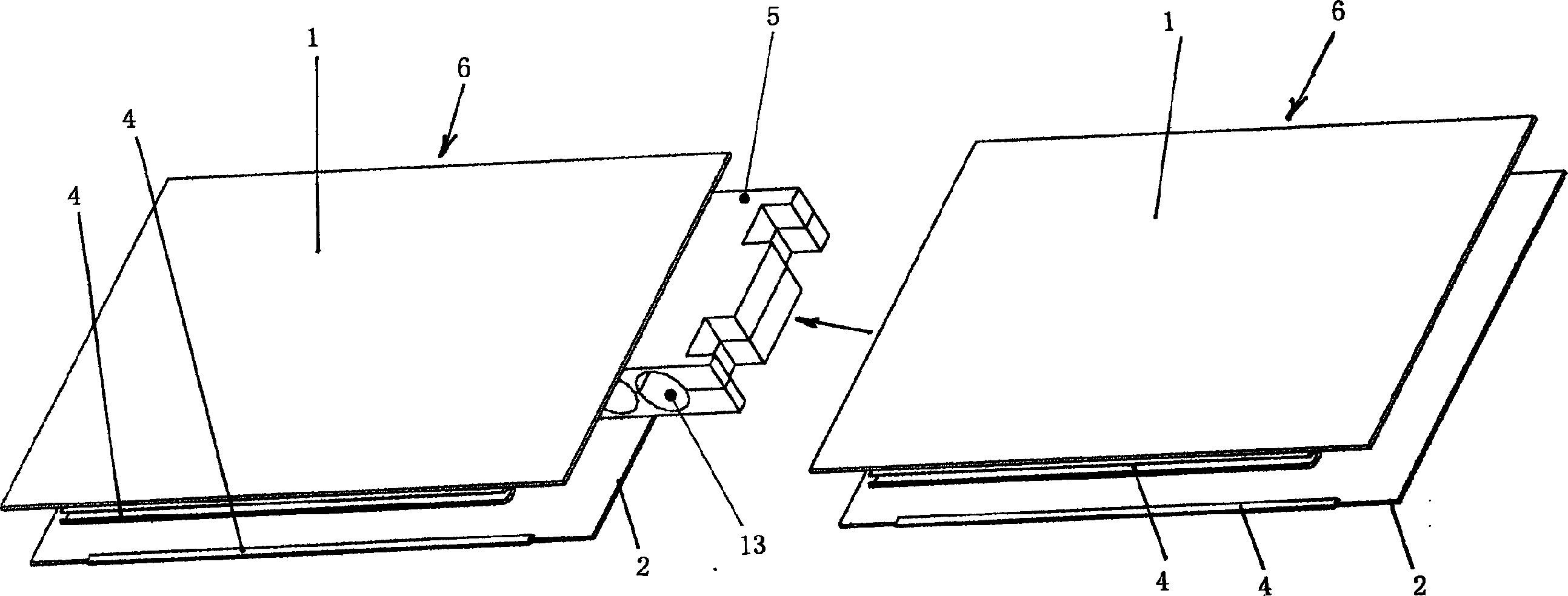

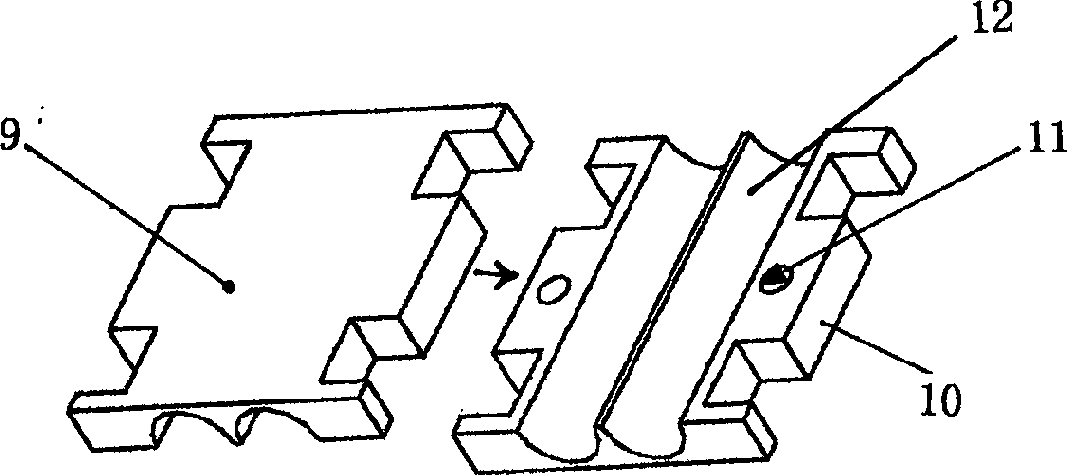

[0044] The temperature control floor of the present invention includes a floor block 6 composed of a floor layer 1, a base layer 2, and a supporting rib 3 formed between the floor layer 1 and the base layer 2, and each floor block 6 is formed on the floor layer 1 and the base layer 2. The horizontal connection locks 4 on both sides of the floor are connected horizontally, and are connected longitudinally through the longitudinal positioning connectors 5 that can be embedded in the longitudinal ends of the floor board 6, thereby forming an integral floor.

[0045] The first implementation of the present invention is as figure 1 , figure 2 As shown, the floor block 6 composed of the floor layer 1, the base layer 2, and the supporting ribs 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com