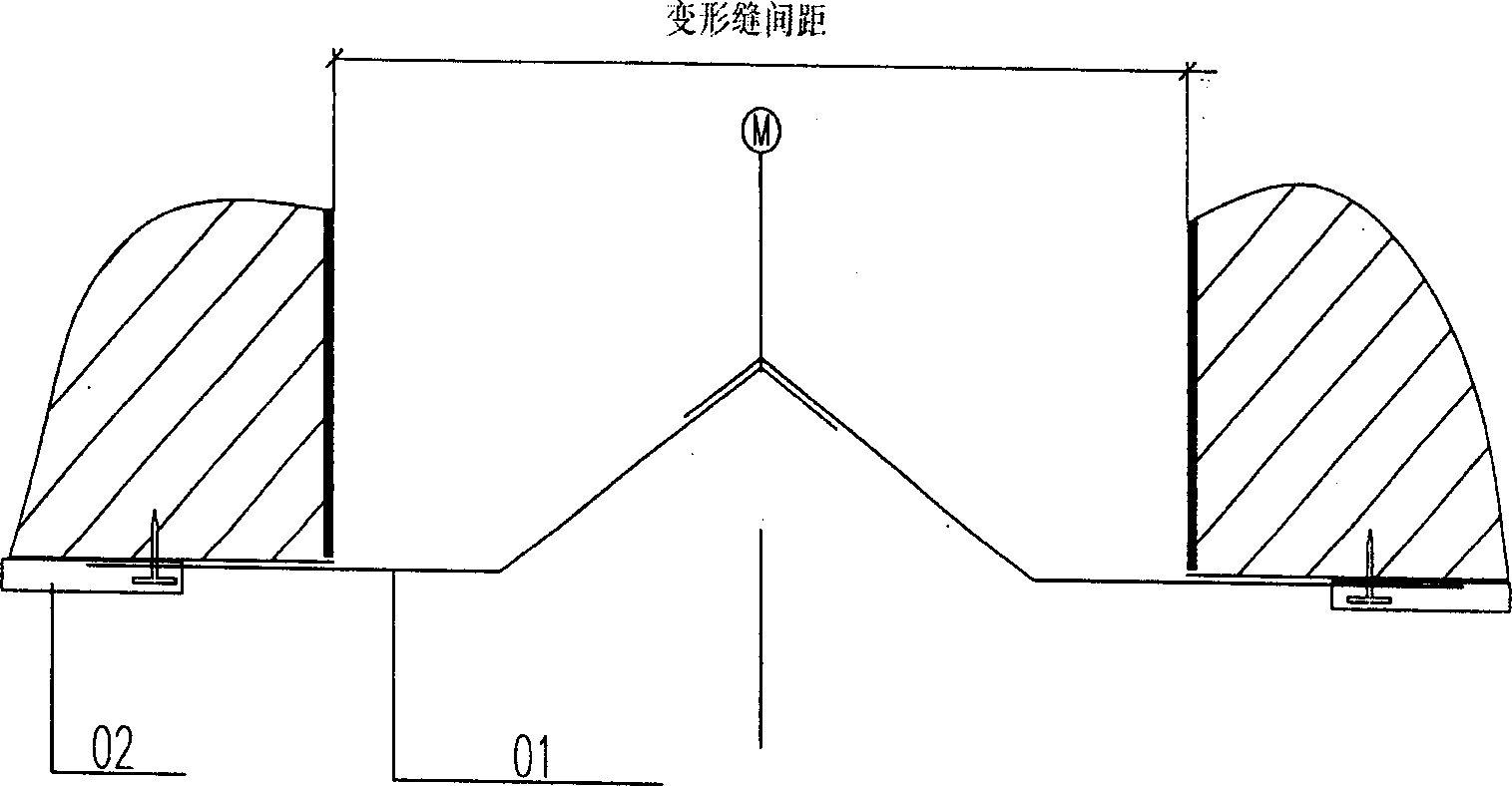

Deformation slot set

A technology of deformation joints and adhesive layers, which is applied to building components, building insulation materials, etc., can solve the problems of easy rusting of metal plates, weak adhesion of painting, and poor adhesion of painting layers and metal plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

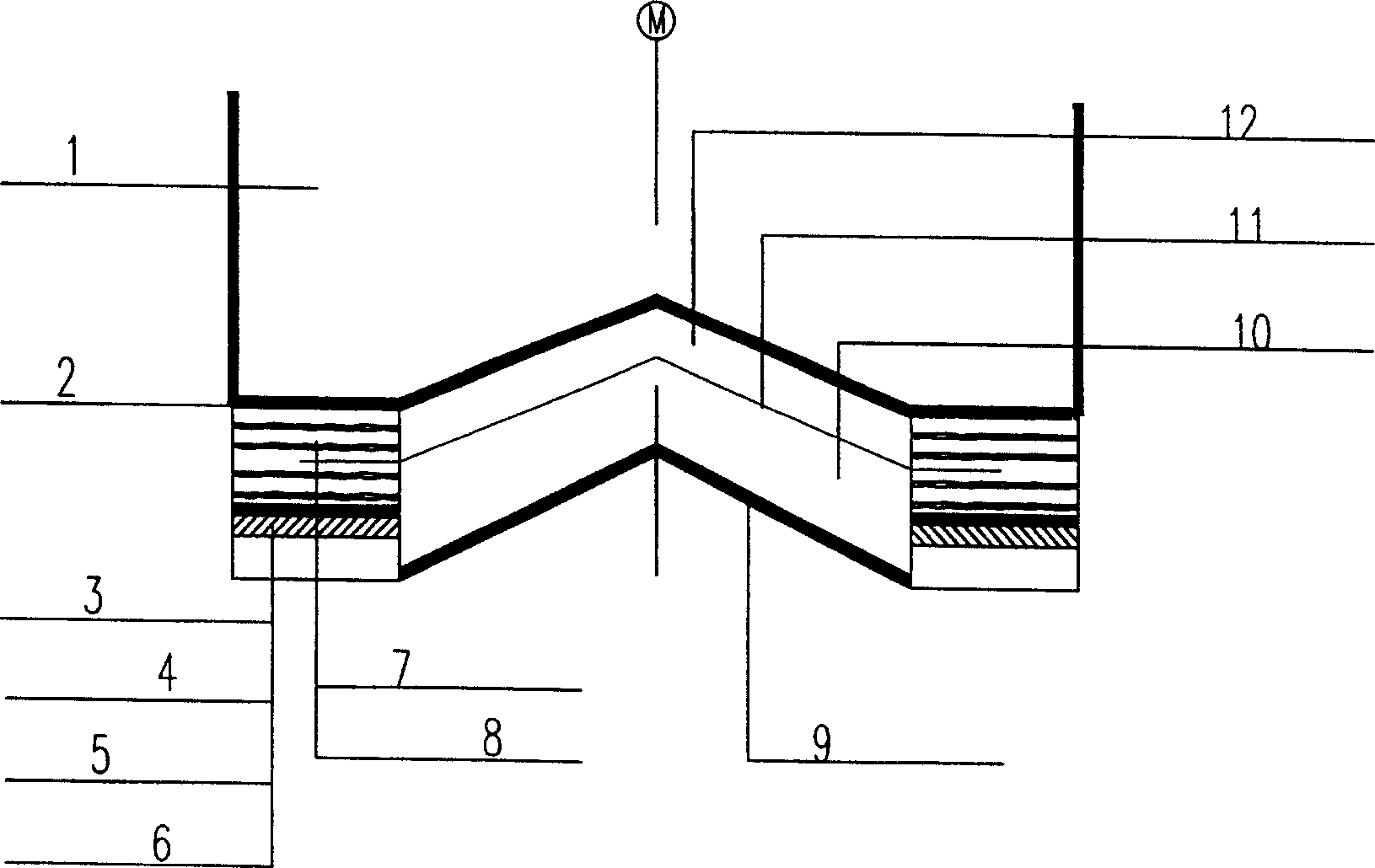

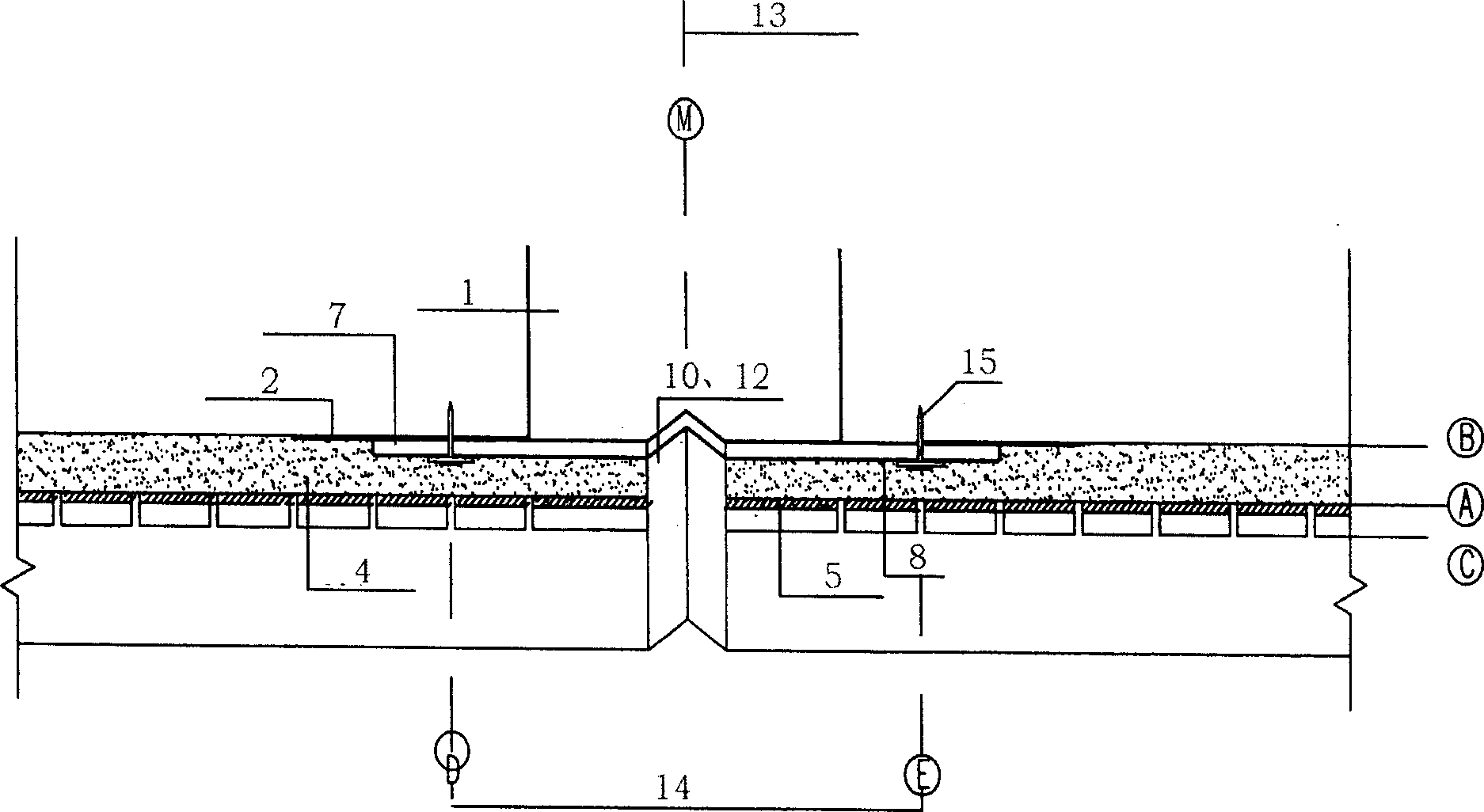

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as figure 2 As shown, the deformation seam device proposed by a preferred embodiment of the present invention includes two adhesive layers 7, a second layer of polysulfide glue waterstop 10, The first layer of polysulfide glue waterstop 12 and nylon mesh cloth 11, the second paste layer 7 is pasted and attached to both sides of the deformation joint by the quartz sand layer 8, cement mortar interface agents 2 and 3, mortar 4, and brick adhesive 5. On the face brick 6 of the main structure of the side. The nylon grid cloth 11 is embedded in the second adhesive layer 7, and the disulfide rubber waterstops 10, 12 are pasted and attached to the two sides of the nylon mesh cloth 11 and the second adhesive layer 7 in an inverted V shape. In addition, the first layer of polysulfide waterstop 12 is attached to the polystyrene foam board 1 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com