Self-acting mule

A spinning machine, automatic technology, applied in the direction of spinning machine, continuous winding spinning machine, intermittent winding spinning machine, etc., can solve the problems of limited flexibility, large production and use of energy, etc., to achieve Effect of reduced yield loss, increased yield, low energy requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

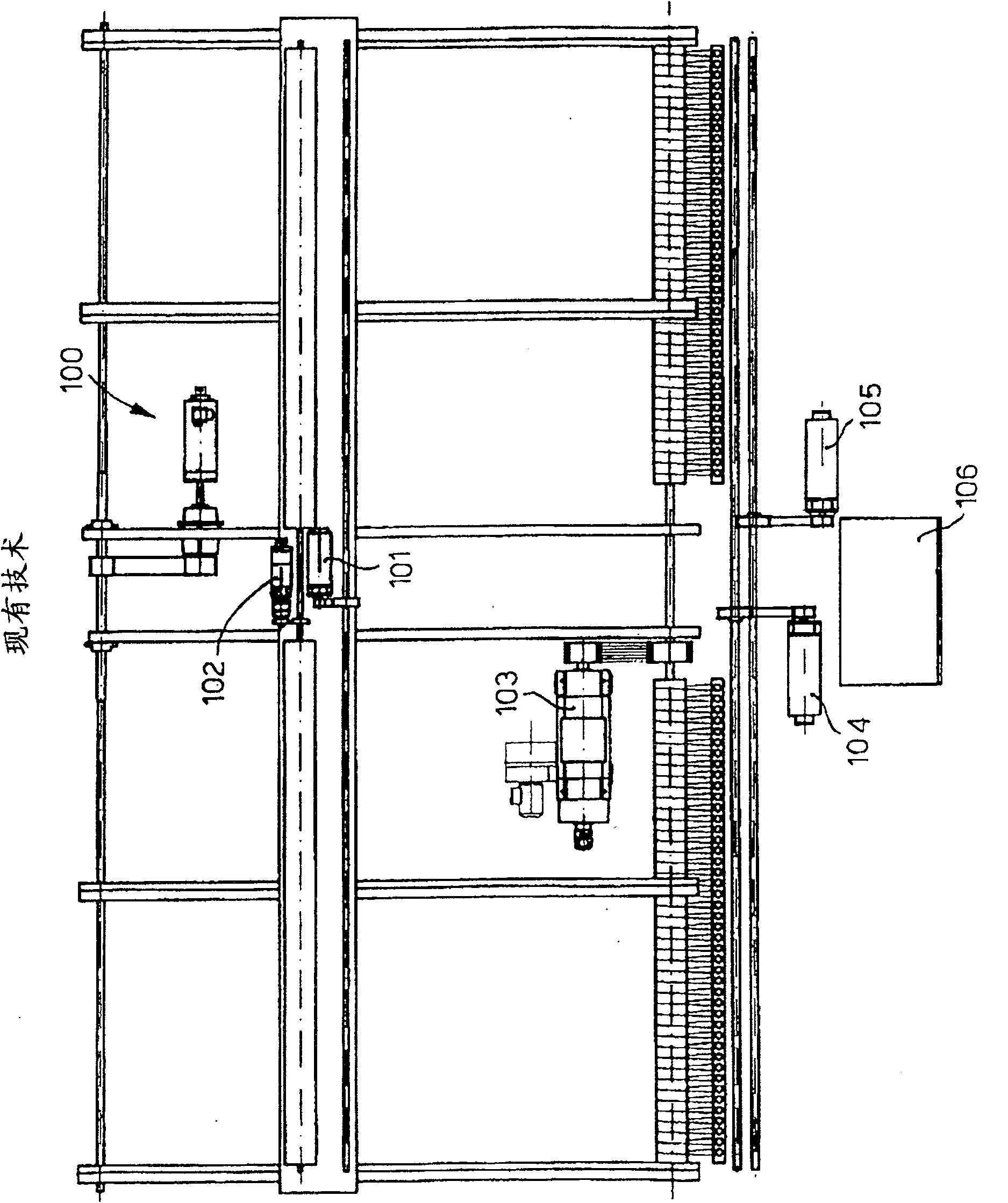

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

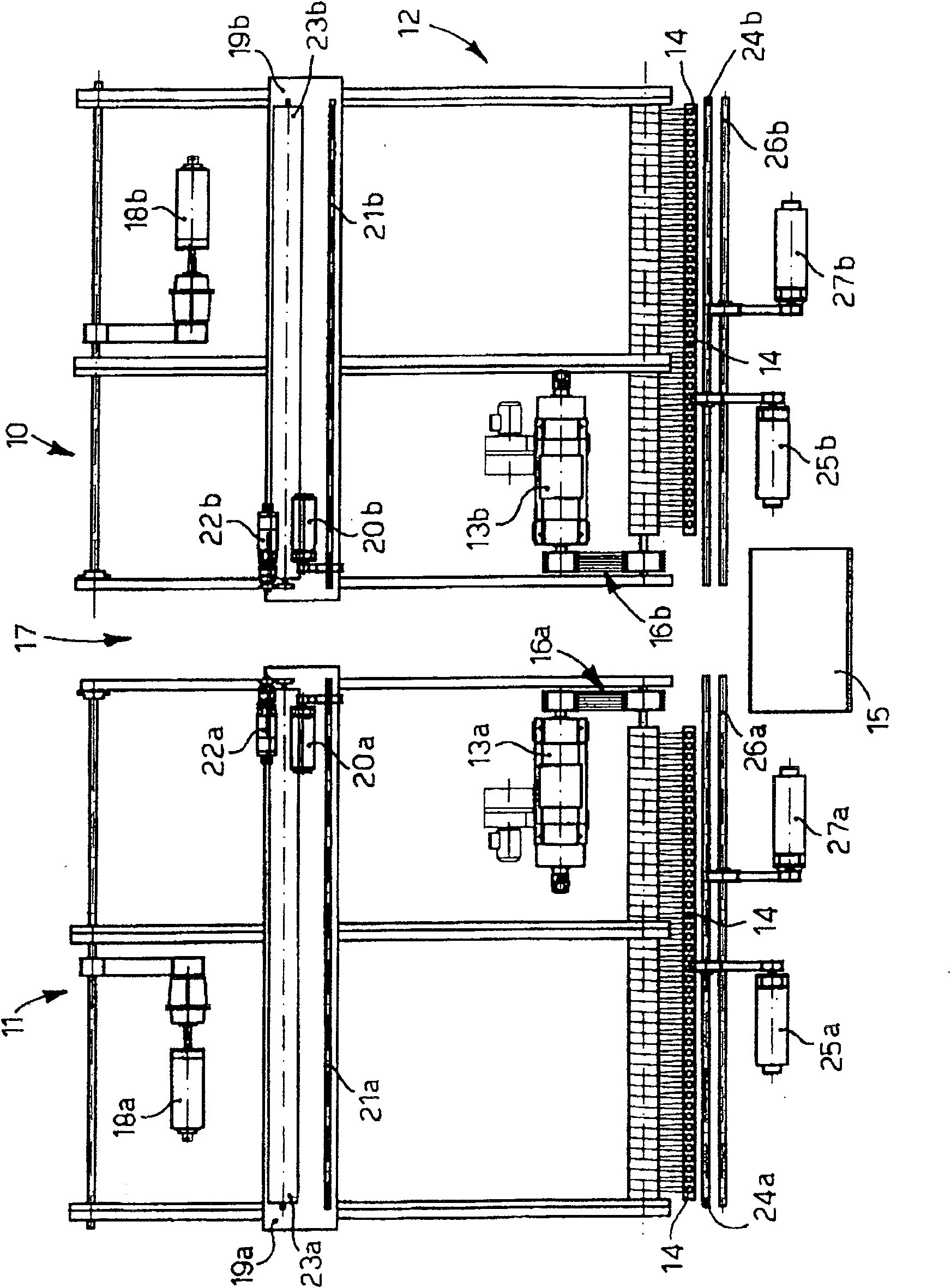

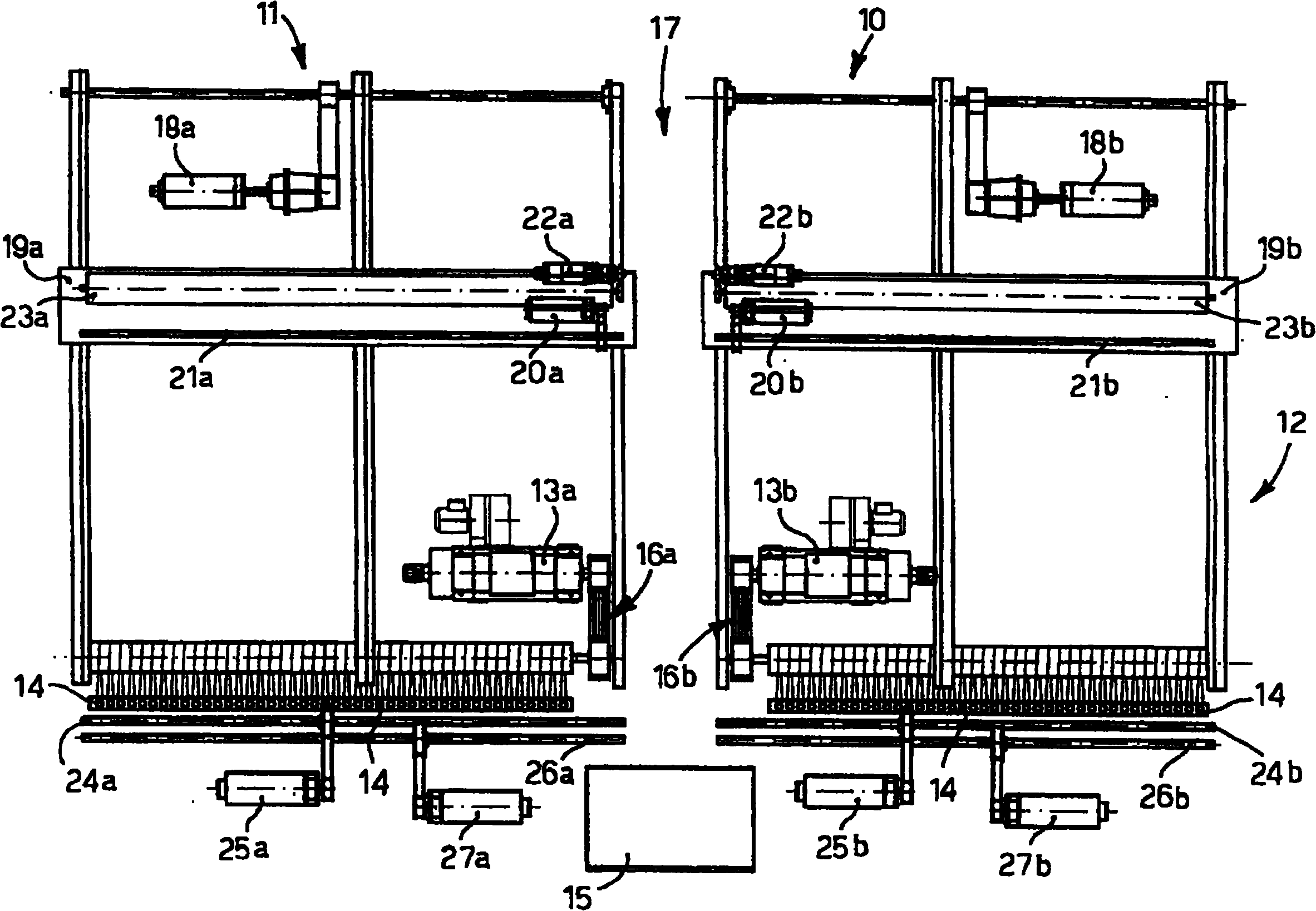

[0052] refer to figure 2 , the automatic spinning machine according to the present invention is indicated by reference numeral 10 as a whole. The automatic spinning machine 10 of the preferred embodiment comprises two parts, respectively a left part 11 and a right part 12, independent of each other from a mechanical point of view, in which case they share a control unit 15 with a corresponding electrical control panel . It is also within the scope of the invention that each section 11 and 12 may be provided with its own automatic control unit and its own electrical control panel.

[0053] The two parts 11 and 12 comprise the individual components of a common automatic spinning machine of conventional type, such as spindles, cylinders, drop bars, drawing drop bars, drums for winding the unwinding reel, reel bearing brackets, etc., whose drives as described below.

[0054] The two parts 11 and 12 can also be of similar size and arranged substantially in line with each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com