Shielded electronic circuit unit and method of manufacturing the same

A technology of electronic circuit and manufacturing method, which is applied in the direction of printed circuit manufacturing, multilayer circuit manufacturing, circuit, etc., can solve the problems of insufficient electric shielding, unreliable adhesion, insufficient circulation of electroplating solution, etc., and achieve good electric shielding, connection Reliable condition, good cycle results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

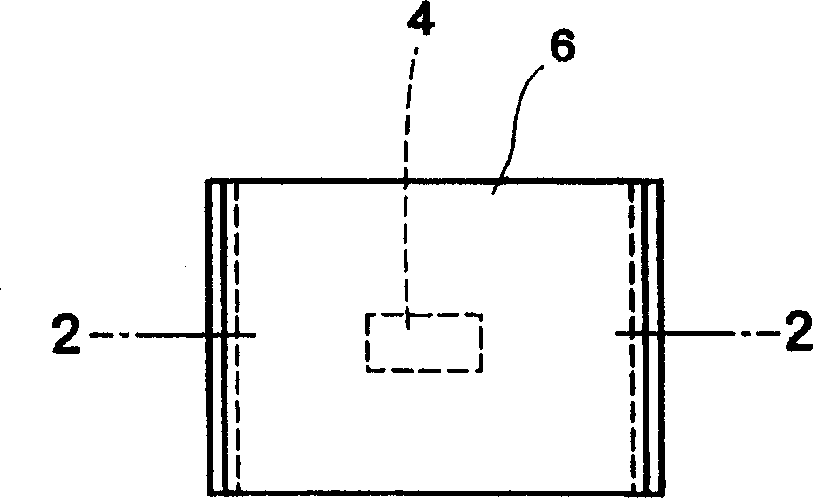

[0099] The accompanying drawings illustrating the electronic circuit unit of the present invention and its manufacturing method, figure 1 is a top view of the first embodiment of the electronic circuit unit of the present invention, figure 2 Yes figure 1 A cross-sectional view of the 2-2 line, image 3 It is a plan view showing the first step of the manufacturing method of the first embodiment of the electronic circuit unit of the present invention, Figure 4 is a sectional view showing the first step of the manufacturing method of the first embodiment of the electronic circuit unit of the present invention, Figure 5 It is a sectional view showing the second step of the manufacturing method of the first embodiment of the electronic circuit unit of the present invention, Image 6 It is a plan view showing the third step of the manufacturing method of the first embodiment of the electronic circuit unit of the present invention, Figure 7 is a sectional view showing the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com