Two-bottle anti-riot smoke disperser and its powder filling method

An anti-riot spray and disperser technology, which is applied in the field of anti-terrorism and anti-riot non-lethal weapons, can solve the problems of complex structure of the trigger valve, inability to perform continuous operation, and small coverage area, and achieve the effects of simple structure, convenient production and large diffusion area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

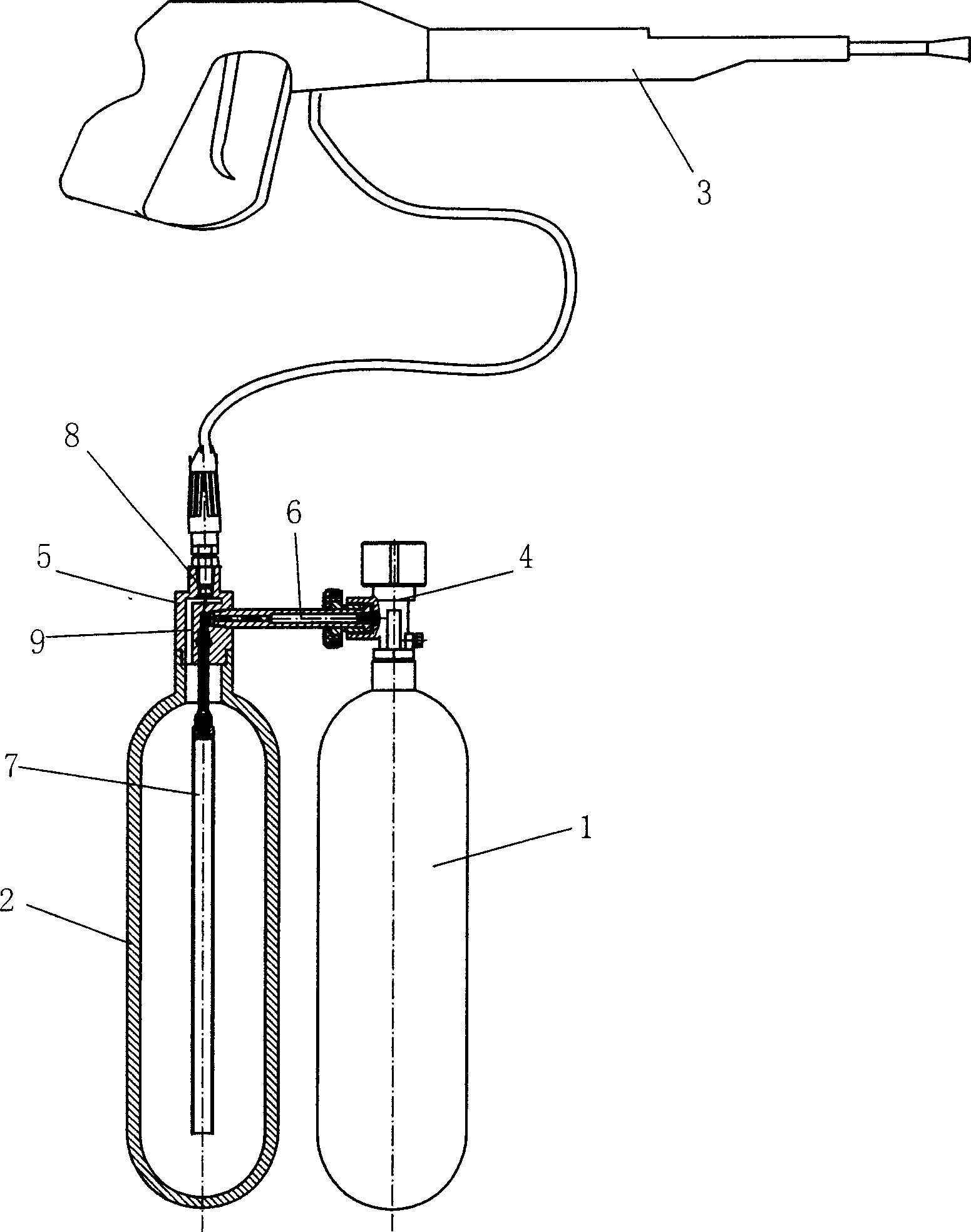

[0043] figure 2 It is a structural diagram of an embodiment of the double-bottle anti-riot spray disperser of the present invention. As shown in the figure, it is mainly composed of a gas bottle 1, a powder bottle 2 and a spray gun 3. The mouth of the gas bottle 1 is provided with The shut-off valve 4 is provided with an air powder head 5 at the mouth of the powder bottle 2, and one side of the air powder head 5 is provided with a connecting pipe 6, and the powder bottle 2 is connected to the gas cylinder 1 through the connecting pipe 6. The connection mode of the pressure gauge is the same. The center of the air powder head 5 is provided with a gas pipe 7 inserted into the bottom of the powder bottle. image 3 , 4 ), the gas powder head is provided with a plurality of through holes 9 communicating with the powder outlet 8 and the powder bottle around the trachea 7, the general through holes are 5, and the diameter is 2 millimeters.

[0044] The operation process is:

[00...

Embodiment 2

[0049] Although the double-bottle anti-riot spray disperser provided by Embodiment 1 solves the problems of increasing power, reducing weight, and continuously spraying, it still has the problem of troublesome powder filling operation.

[0050] 1. When filling the powder, use the rotating fixture to remove the powder filling head from the powder bottle, and then tighten the powder filling head after filling the powder. During the operation, the mouth of the bottle and the contact surface must be cleaned. If it is a little sloppy, the spraying effect will be affected due to the lack of sealing. And damage the powder bottle.

[0051] 2. In the above operation process, the operator will have more contact with powder.

[0052] 3. The powder filling machine has a complex structure and a large volume, and it also needs to be equipped with a rotating fixture.

[0053] 4. The powder outlet channel of the air powder head of the above-mentioned anti-riot spray disperser is a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Relative air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com