Horizontal positive-displacement energy-saving electric water heater

An electric water heater, volumetric technology, applied in the field of horizontal electric water heaters, can solve the problems of short flow, limited energy saving effect, high cost, etc., and achieve the effects of avoiding short flow, simple structure, and reducing the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

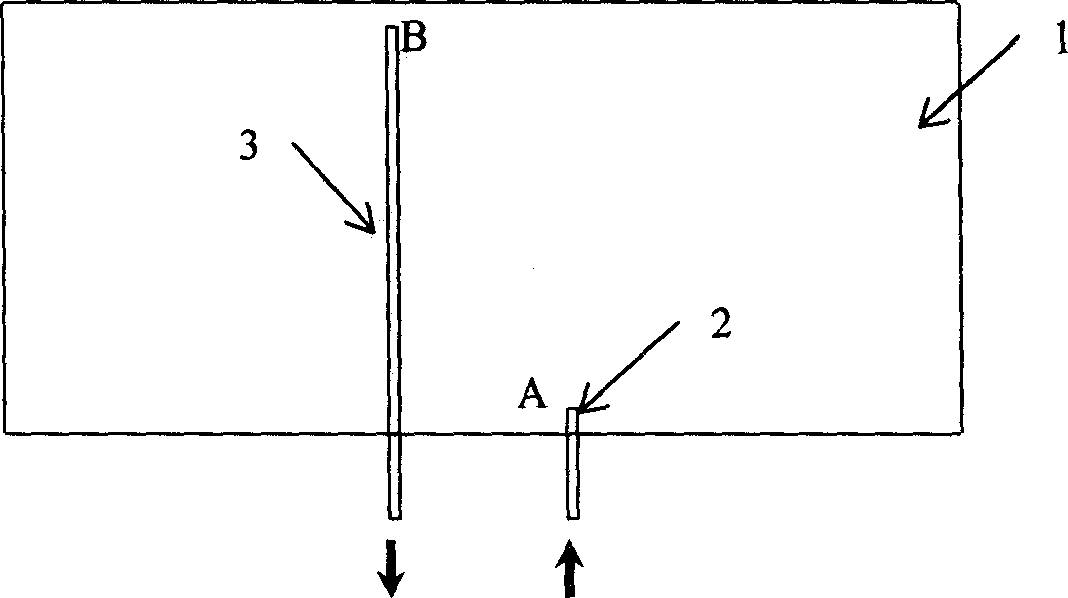

Embodiment 1

[0024] The structure of the horizontal volumetric energy-saving electric water heater described in this embodiment is as follows: image 3 , Figure 4 As shown, it includes a shell 4, an inner tank 1, a cold water input pipe 2 combined with the inner tank and a hot water output tube 3, a temperature sensor 8 installed in the inner tank and heating elements 6, 7, connected with the temperature sensor and the heating element The heating controller 9. The liner 1 is a cylinder, and the axis of the cylinder is provided with a partition 5 that blocks the direct mixing of hot and cold water. Formed into one body, there is a distance between the other end and the end face of the inner tank, the distance is less than or equal to 1 / 8 of the length of the inner tank, and this distance is the passage for cold water to enter the hot water area; The material is high-density polyurethane. The cold water input pipe 2 is an elbow, and the pipe body inserted into the inner tank is located u...

Embodiment 2

[0026] The structure of the horizontal volumetric energy-saving electric water heater described in this embodiment is as follows: Figure 5 , Figure 6 shown. The differences from Example 1 are: 1. The liner 1 is a rectangular cylinder, and the separator 5 is a sandwich hollow plate, which is connected to the liner 1 by welding. 2. The hot water output pipe 3 is inserted into the tube body of the inner tank and enters the upper space of the inner tank from the distance between the end of the partition plate 5 and the end face of the inner tank 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com