Double-induction resistivity measuring instrument during drilling

A technology of inductive resistance and measuring instrument, which is used in surveying, earthwork drilling, wellbore/well components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

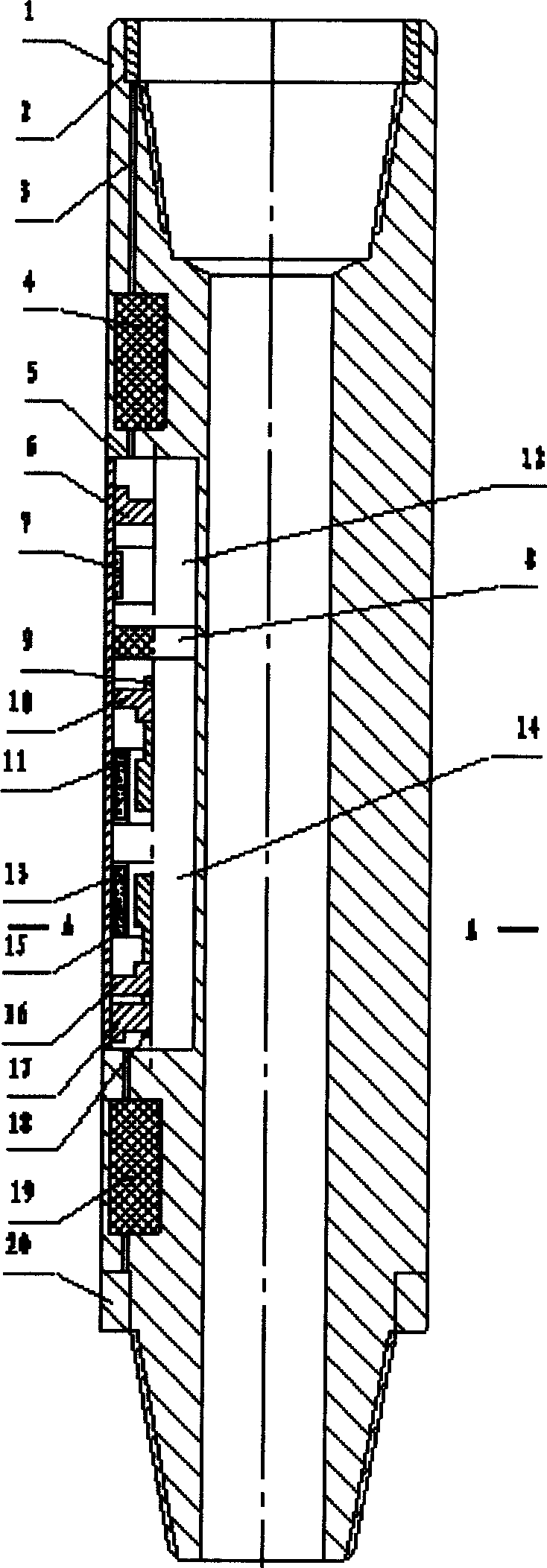

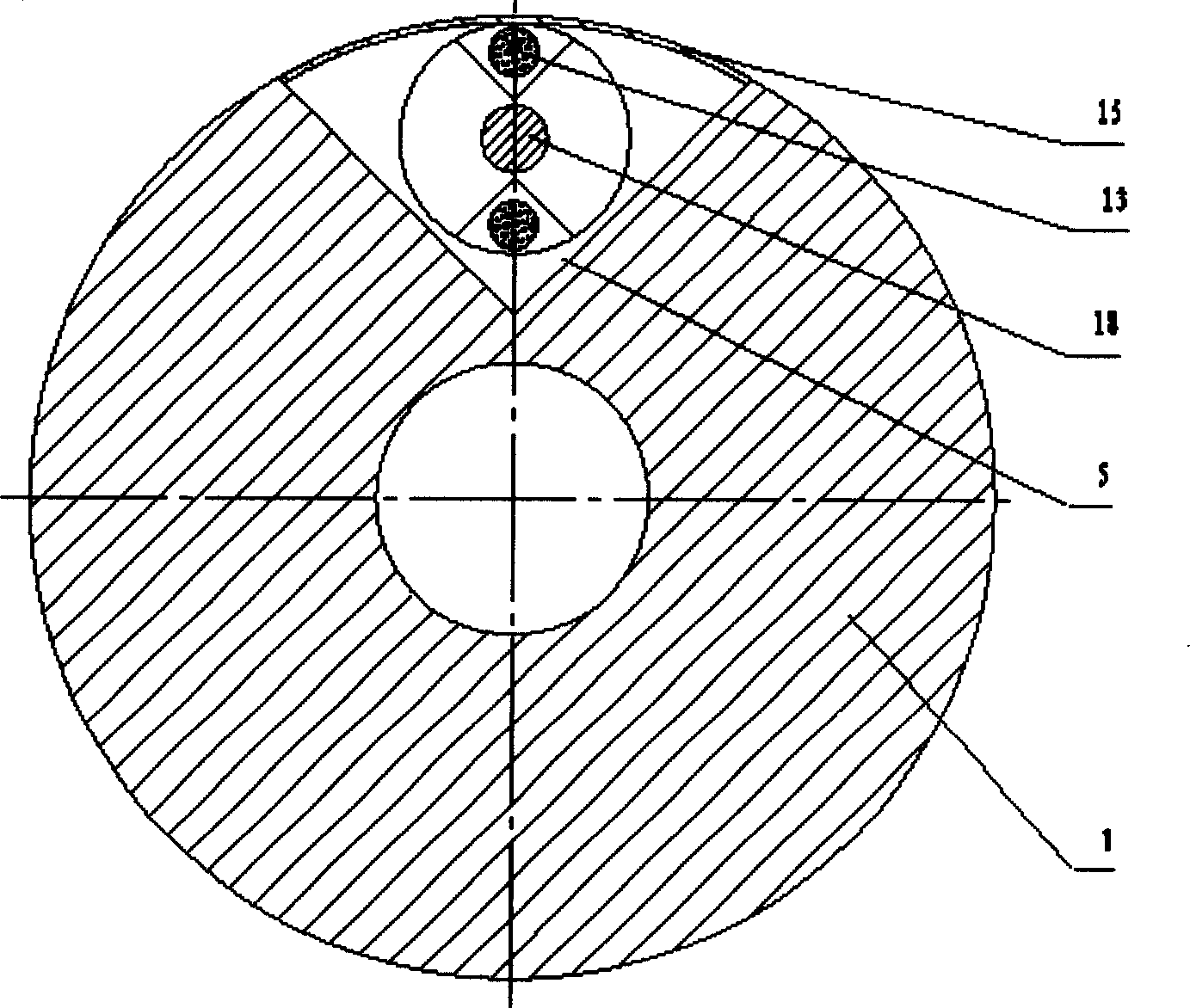

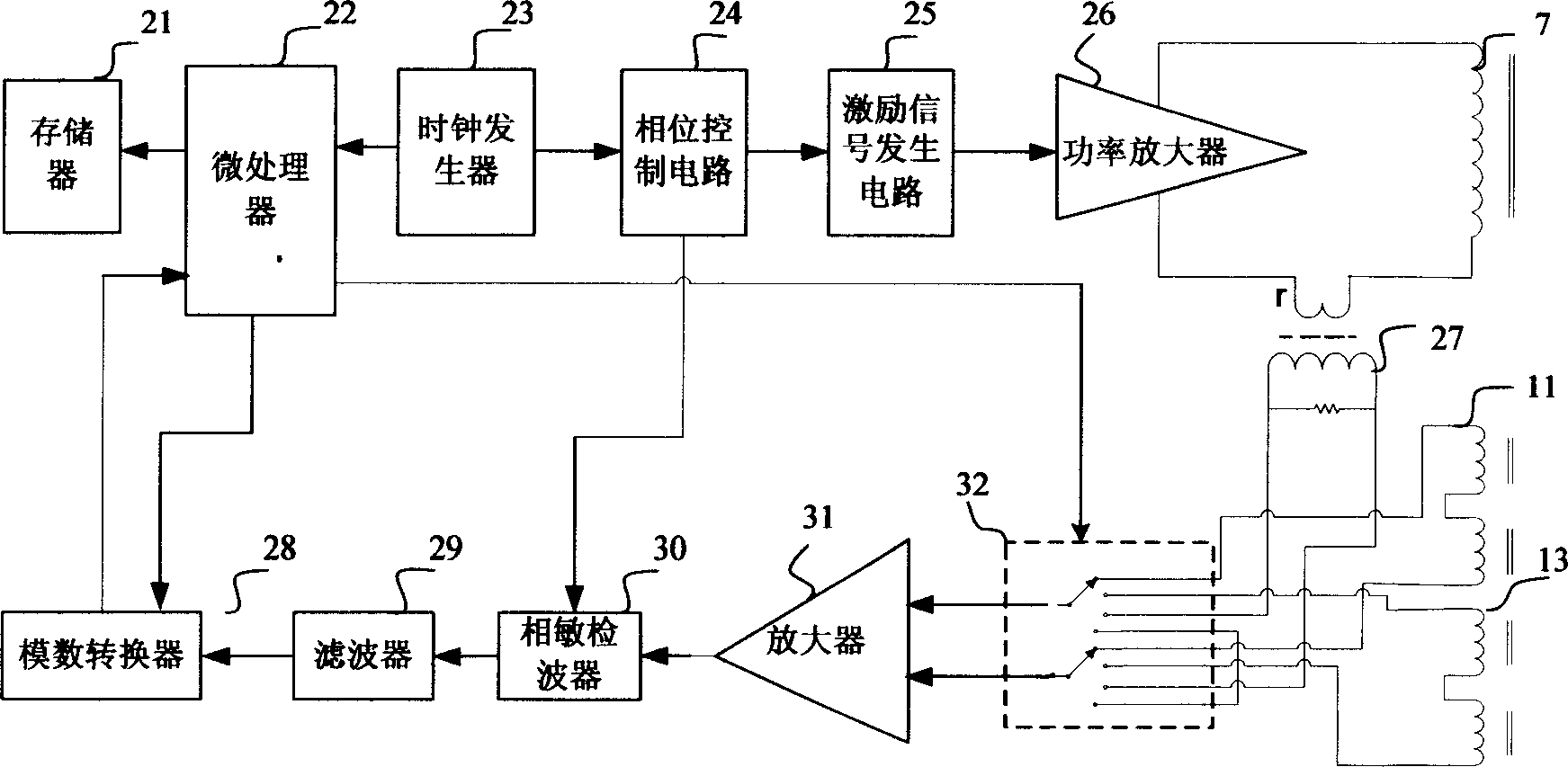

[0030] Now combined with the manual figure 1 , 2 and 3, the present invention is further described.

[0031] figure 1 with figure 2 Represents the axial and radial sections of the instrument. The drill collar 1 is used as the installation skeleton of the instrument and a part of the downhole drilling tool, and is located behind the drill bit or the deflection tool. There is a V-shaped groove 5 on any side of the drill collar. The coupling unit 8 connects the transmitting unit 12 and the receiving unit 14 and installs them in the V-shaped groove 5 to form an electrode system. The high-pressure sealing cover plate 15 is pressed on the V-shaped groove. 5, the transmitting unit 12 is equipped with a transmitting coil 7 and a hydraulic balance piston 6, and the receiving unit 14 is equipped with a deep detection receiving coil 11, a deep detection balance adjustment screw sleeve 10, a deep detection balance adjustment screw 9, and a shallow detection receiver. Coil 13, shallo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com