Construction method for weakening zone of floor plate wall rock

A technology of floor and surrounding rock, which is applied in the deformation control of floor drum and surrounding rock, and in the field of controlling deformation of surrounding rock in other high-stress underground projects. Distribution status, lower kick drum, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

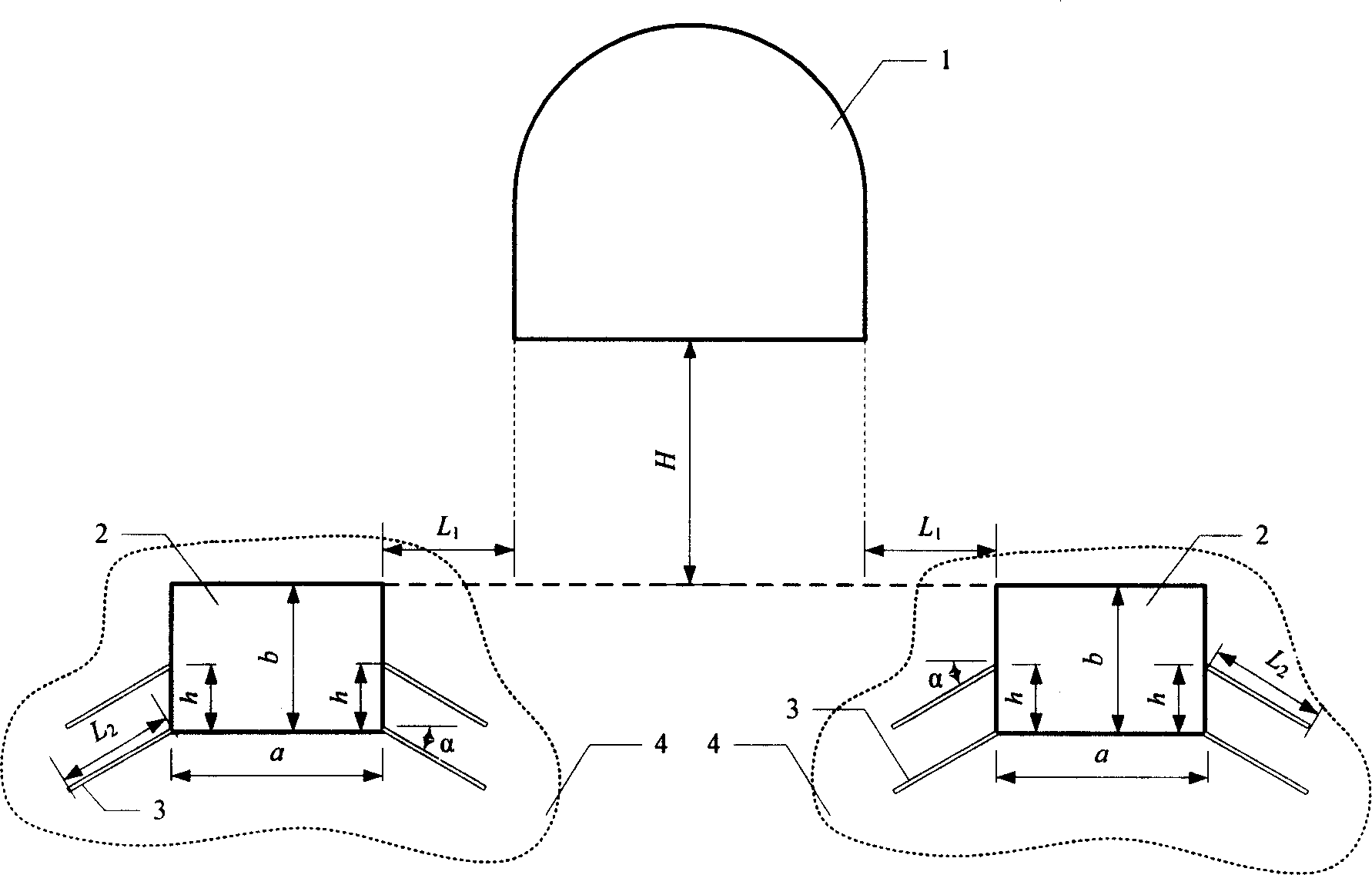

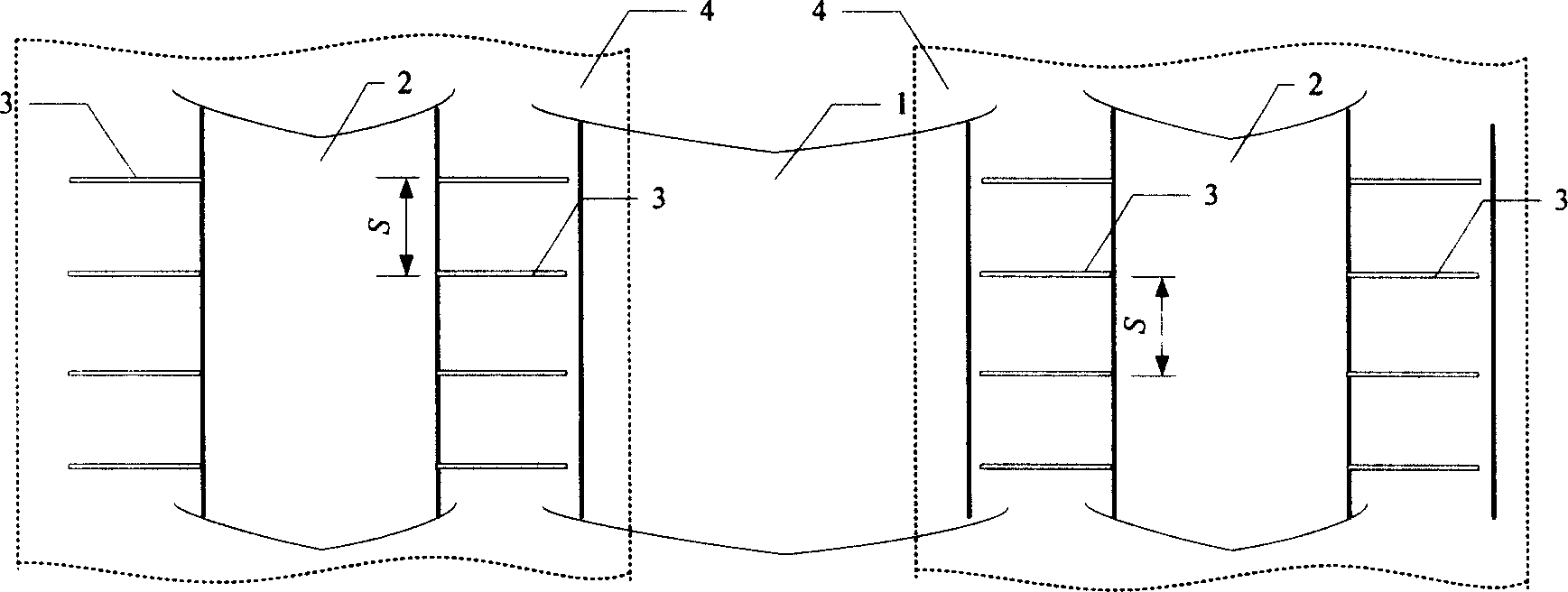

[0010] A method for constructing a floor surrounding rock weakening area of the present invention is to excavate two stress transfer roadways 2 in a horizontal direction at a vertical distance H of 4.0 m from the floor of the cavern or roadway 1 to be protected, and the two stress transfer roadways 2 are separated by To protect the horizontal distance L outside the chamber 1 is 1.0m, and the two stress transfer roadways 2 are rectangular sections with a width of 3m and a height of 2m, and the sections can also be circular, arched or trapezoidal. The length of the rectangular stress transfer roadway 2 is the same as the length of the chamber to be protected. If the same length of the protection chamber is 40m, the stress transfer roadway 2 is also 40m. After the construction of the roadway is completed, two holes with an angle of 30° to the horizontal lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com