Super high molecular weight polyacrylamide industrialized production process

A polyacrylamide and ultra-high molecular weight technology is applied in the field of industrialized production technology, which can solve the problems of high salinity of formation water, inability to treat sewage, and inability to meet the tertiary oil recovery technology in oil fields, and achieve the effect of overcoming high reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Equipment and materials

[0030] Dissolving tank (12 tons / pot); reactor (6 tons / pot); columnar material box; feeding pump; twin-screw granulator; feeding fan; hydrolysis machine (4 tons / pot); dryer; grinder ; sifter. 25% Acrylamide; Ethylene Glycol Dimethacrylate; Initiator; Potassium Hydroxide; Nitrogen; Desalted Water.

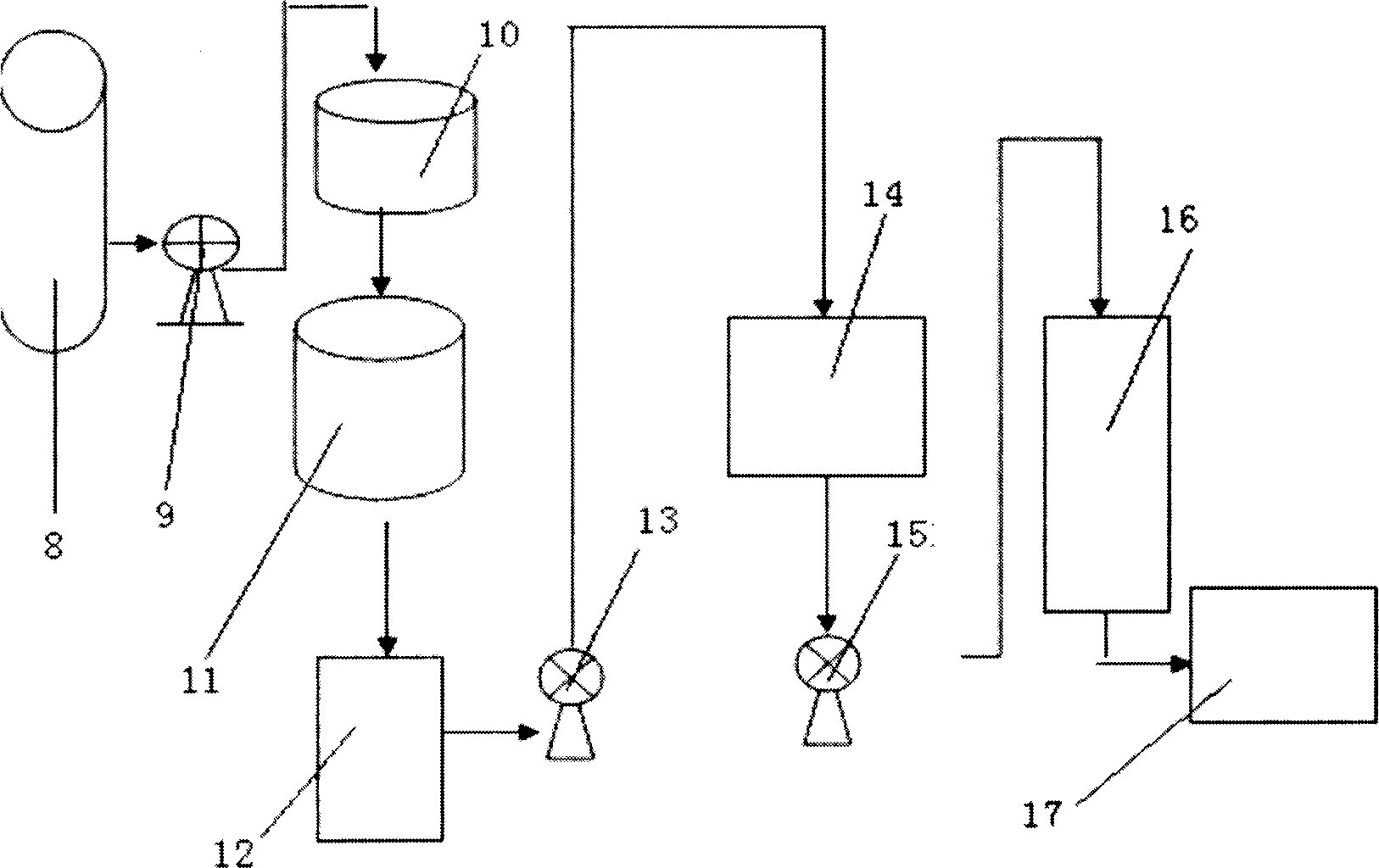

[0031] 2. Operation steps, see figure 2

[0032] 1) The reaction scale is 6 tons. In the dissolution tank (8), 23% acrylamide aqueous solution is prepared with 25% acrylamide and desalted water, and 4% ethylene glycol dimethacrylate is added, and the temperature is adjusted to 5°C. The pH value is adjusted to 7.5-9.0.

[0033] 2) After the reaction mother liquor is prepared, transfer it to the reactor (10) by the dissolving pump (9), blow nitrogen for 1 hour, add a complex initiator to initiate the reaction, and react for about 6 hours.

[0034] a trigger system

Potassium persulfate 0.1%

two-stage in...

Embodiment 2

[0041]The reaction scale is 12 tons: the concentration of acrylamide is 26%, the functional monomer ethylene glycol dimethacrylate is 6%, and the polymerization is initiated by an initiator. The reaction period is 4-7h, and the hydrolysis degree is 28%. 80°C, hydrolysis reaction time 1-5h, after drying, crushing, sieving to obtain ultra-high molecular weight polyacrylamide products with a molecular weight of more than 25 million.

[0042] 1. Equipment and materials

[0043] Dissolving tank (24 tons / pot); Reactor (12 tons / pot); Conveying pump; Rotary knife-sieve plate granulator; Conveying fan; Horizontal hydrolysis machine (8 tons / pot); Dryer; Grinding machine; sifter. 28% acrylamide; initiator; sodium hydroxide; nitrogen; desalinated water.

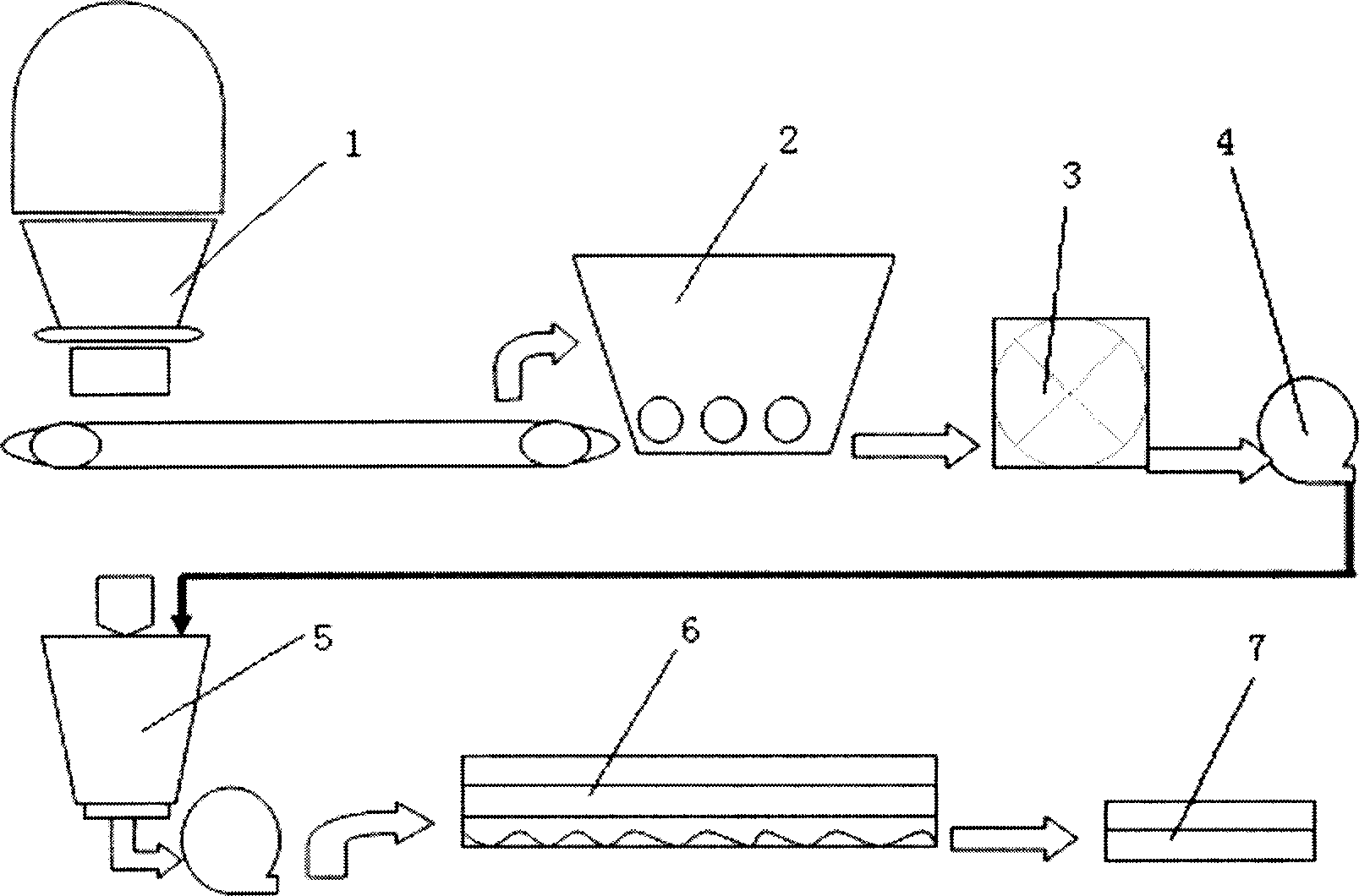

[0044] 2. Operation steps (see figure 1 )

[0045] 1) The reaction scale is 12 tons. In a dissolving tank, use 50% acrylamide aqueous solution, ethylene glycol dimethacrylate and desalted water to prepare a prepolymer liquid by 26% a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com