Electro-static chuck with non-sintered aln and a method of preparing the same

An electrostatic chuck, non-sintering technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of poor bonding and arching of bonding parts, achieve low porosity, reduce residual stress, high The effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention seeks to provide an electrostatic chuck having non-sintered aluminum nitride in which the dielectric layer is formed from a coating of non-sintered aluminum nitride.

[0029] Now, an electrostatic chuck having non-sintered aluminum nitride according to the present invention will be described in detail with reference to the accompanying drawings.

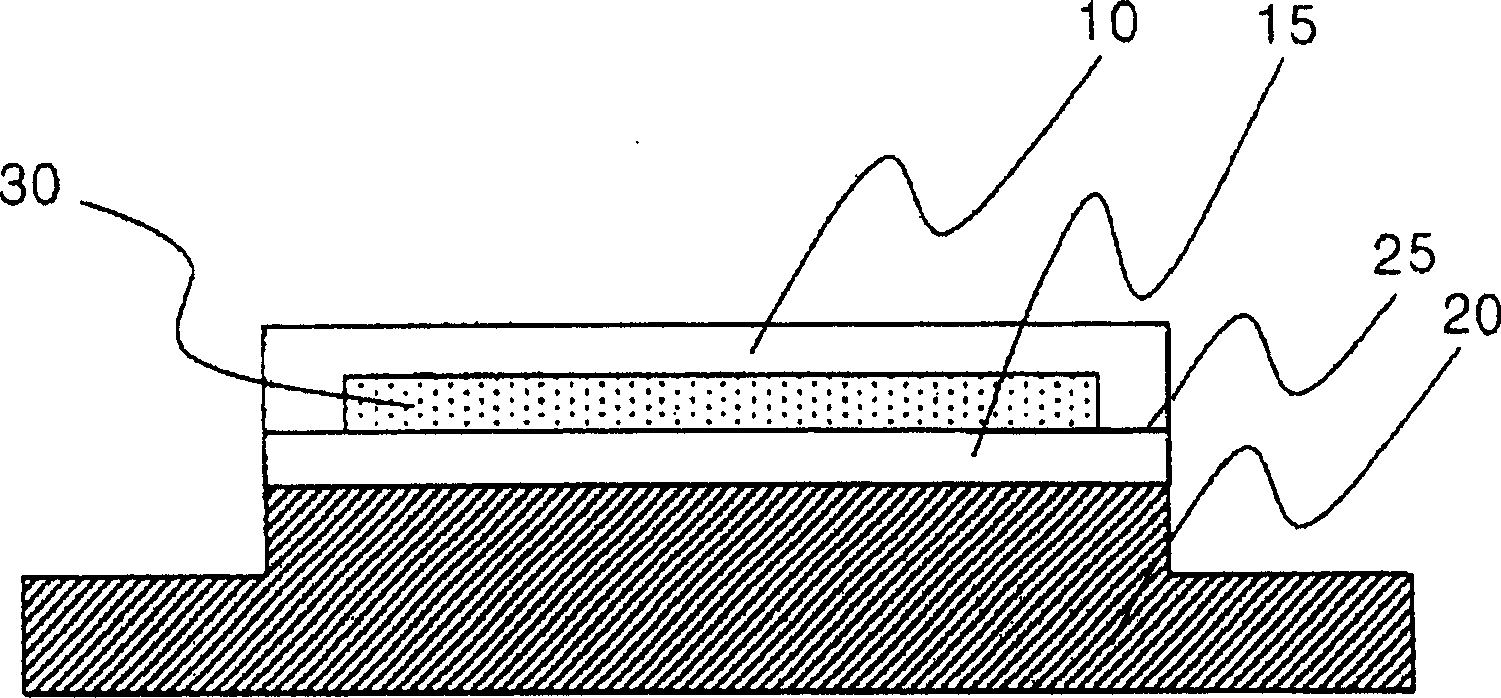

[0030] In a preferred embodiment, an electrostatic chuck with non-sintered aluminum nitride (AlN) according to the present invention includes a substrate 20 , an insulator 15 , an n-electrode 30 and a dielectric 10 .

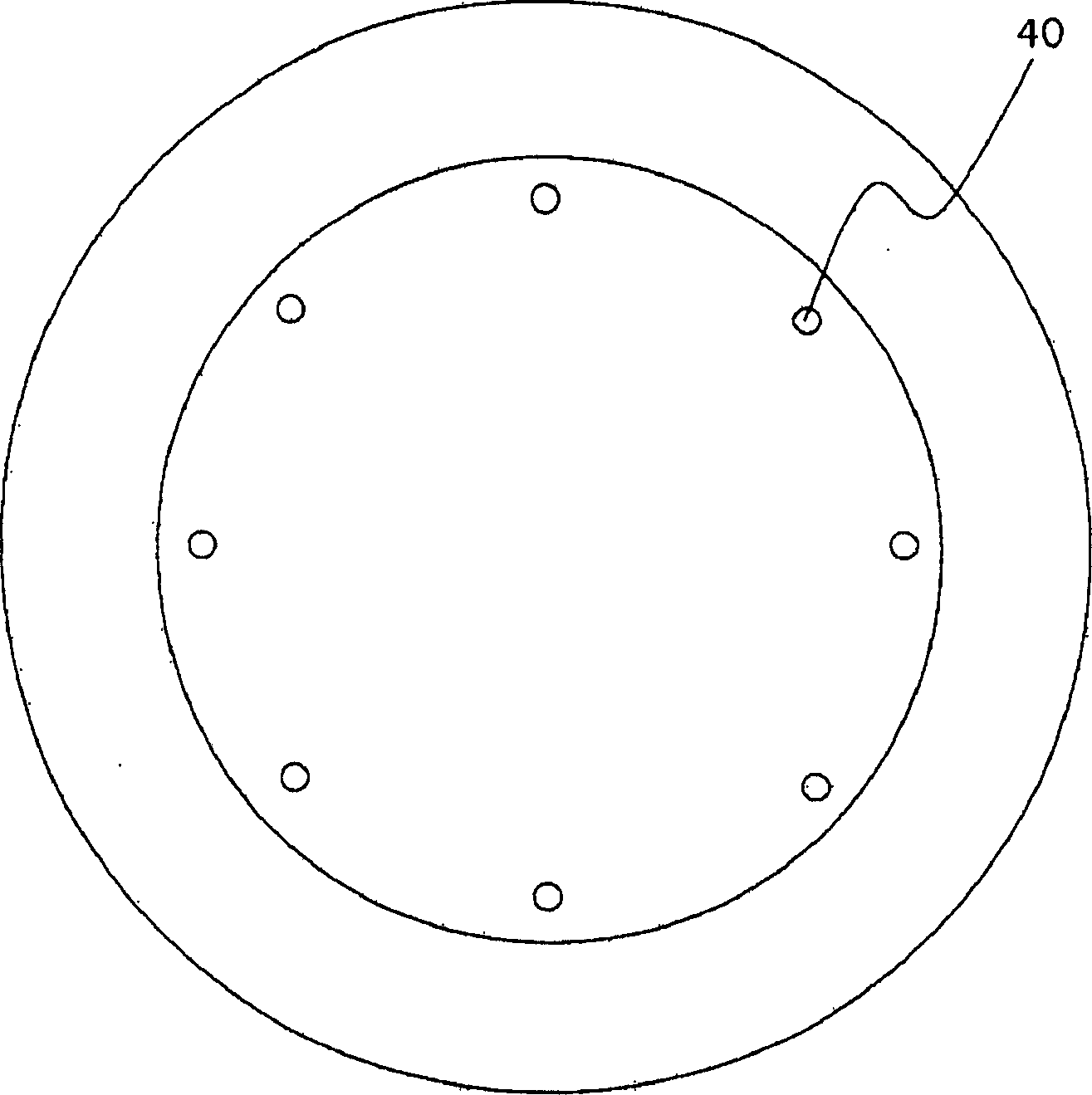

[0031] figure 1 with figure 2 A cross-sectional view and a plan view are shown, respectively, of an embodiment of an electrostatic chuck with non-sintered aluminum nitride (AlN) according to the present invention.

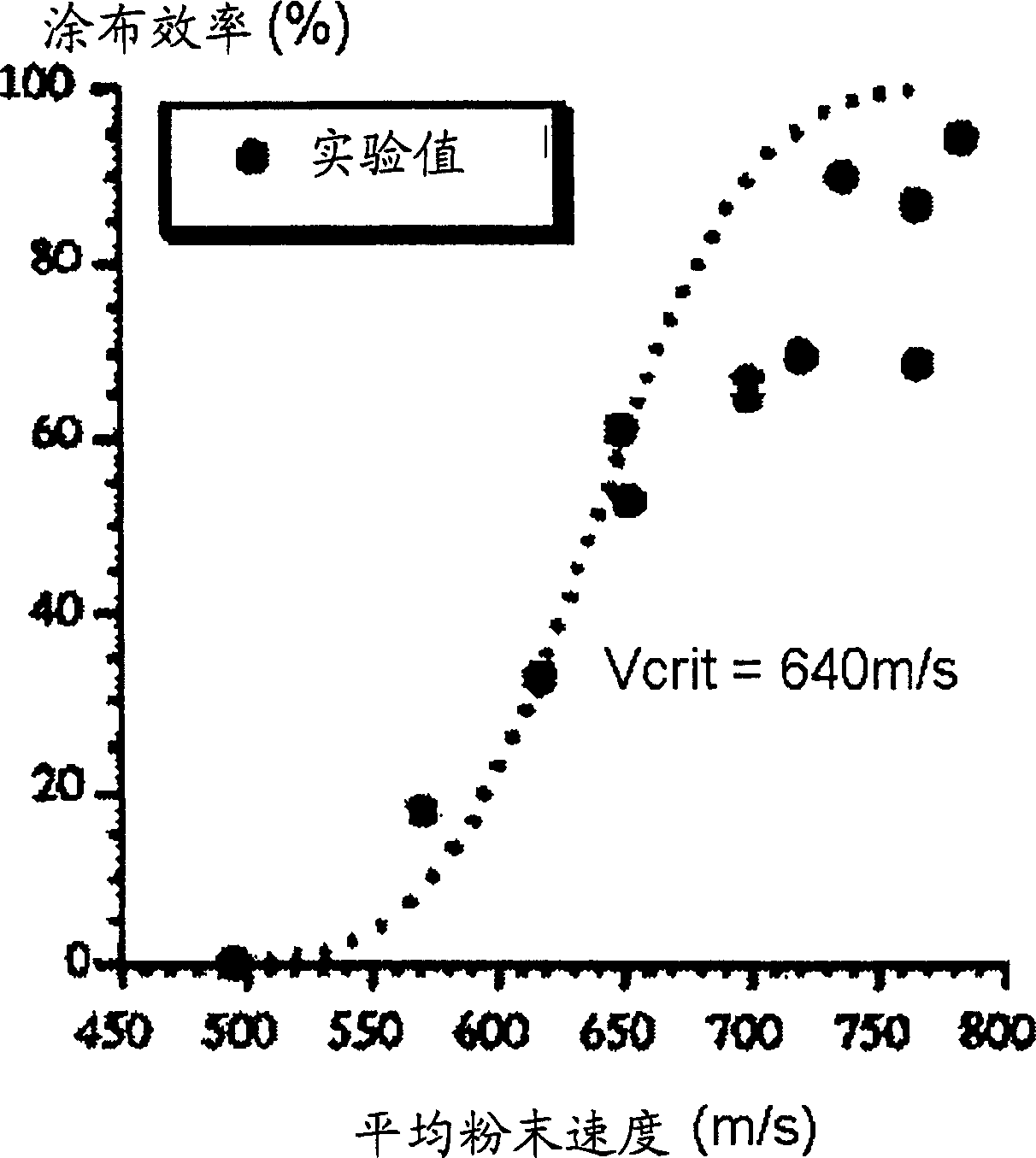

[0032] In the electrostatic chuck having non-sintered aluminum nitride (AlN) according to the present invention, the coating layer of aluminum nitride can be formed by variou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com