Plasma display panel

A plasma and display panel technology, applied in alternating current plasma display panels, gas discharge electrodes, gas discharge tubes/containers, etc., can solve the difficulty in achieving white balance, the plasma display panel is not considered, and the manufacturing cost of the plasma display panel Increase and other problems to achieve the effect of improving brightness, achieving white balance, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

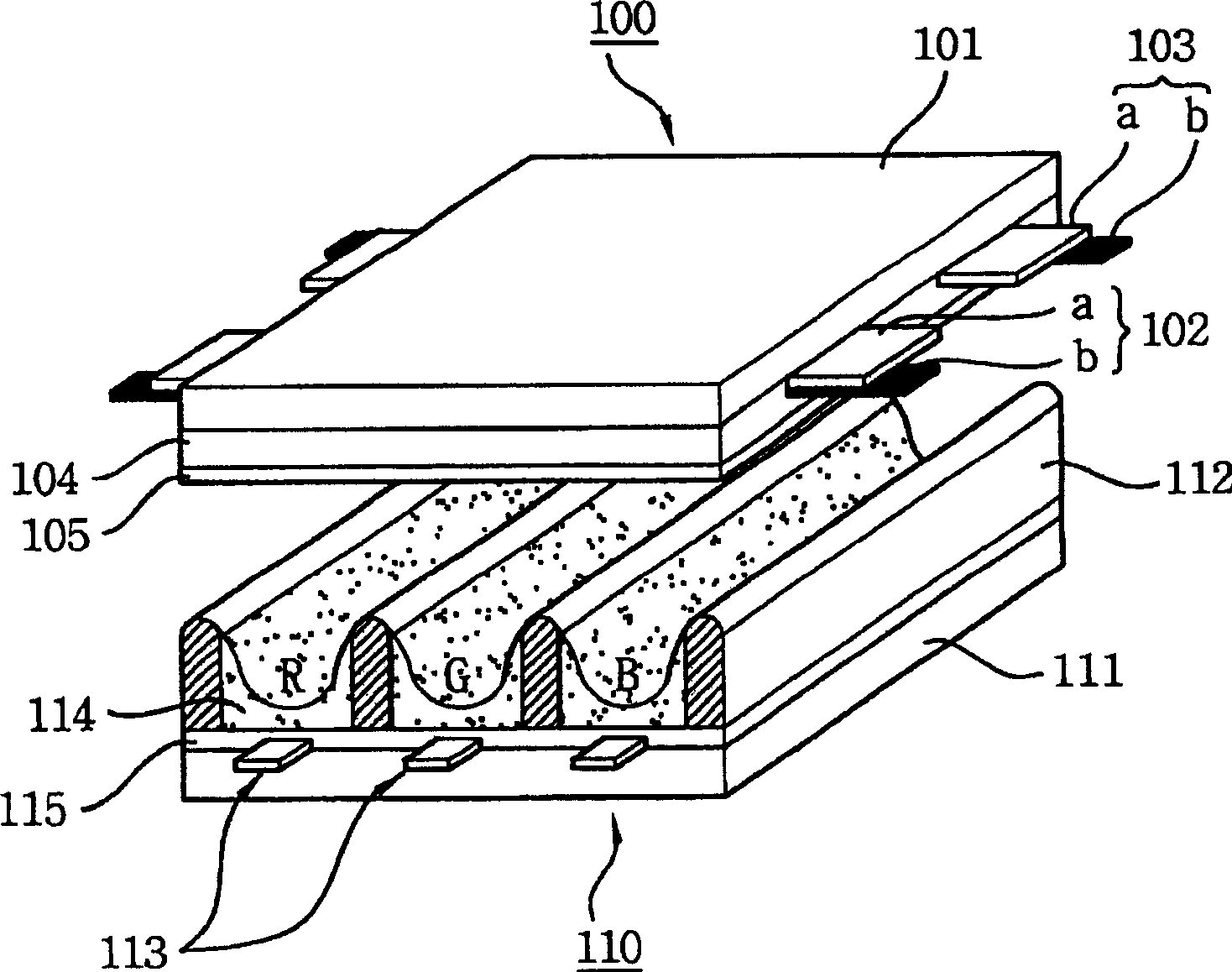

[0039] Reference will now be made in detail to the embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

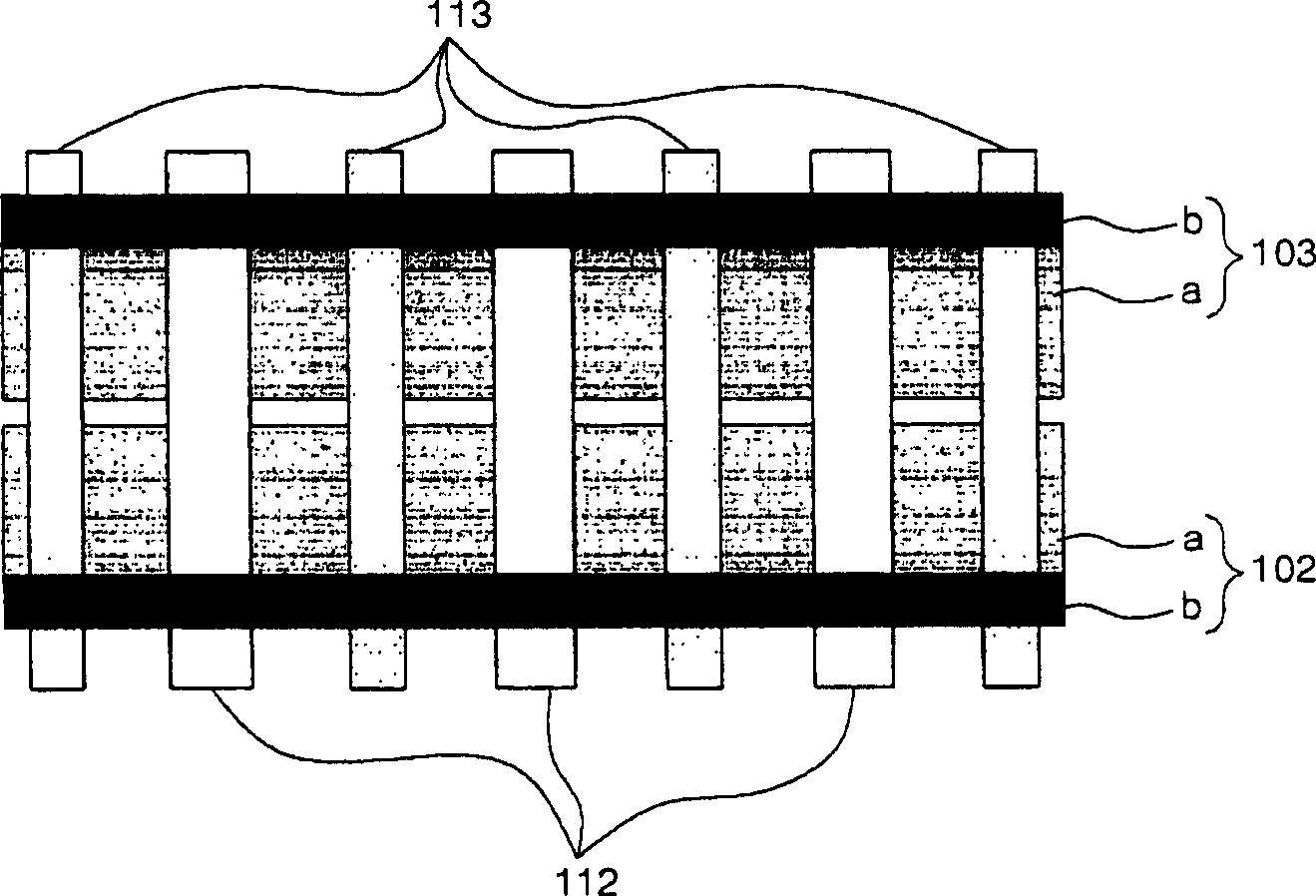

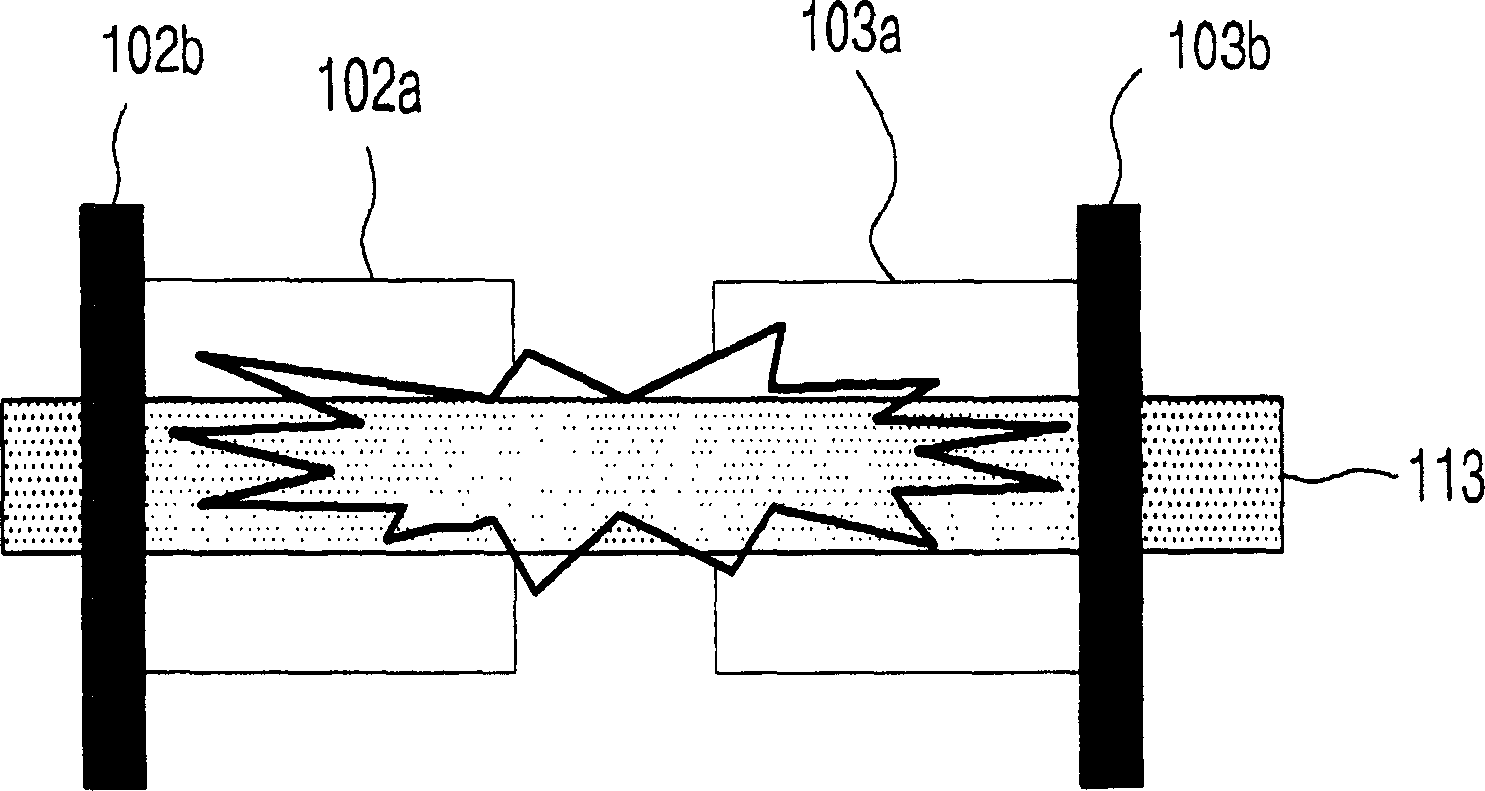

[0040] A plasma display panel according to an aspect of the present invention includes: a front substrate including scan electrodes and sustain electrodes; and a rear substrate including barrier ribs for forming discharge cells, wherein the scan electrodes and sustain electrodes include a plurality of protruding electrodes in the discharge cells section.

[0041] The protruding electrode part may include a first protruding electrode part and a second protruding electrode part.

[0042] The first protruding electrode part may be disposed between the second protruding electrode part.

[0043] The first protruding electrode part may include at least one protruding electrode.

[0044] The second protruding electrode part may include at least two protruding electrodes.

[0045] The first gap between the first protruding electrode por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com