Method of repairing disconnection, method of manufacturing active matrix substrate by using thereof, and display device

An active matrix and substrate technology, applied in the field of display devices and manufacturing active matrix substrates, can solve the problems of display defects, data signal wiring affecting pixel electrode voltage, etc., and achieve the effect of reducing display defects and improving output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

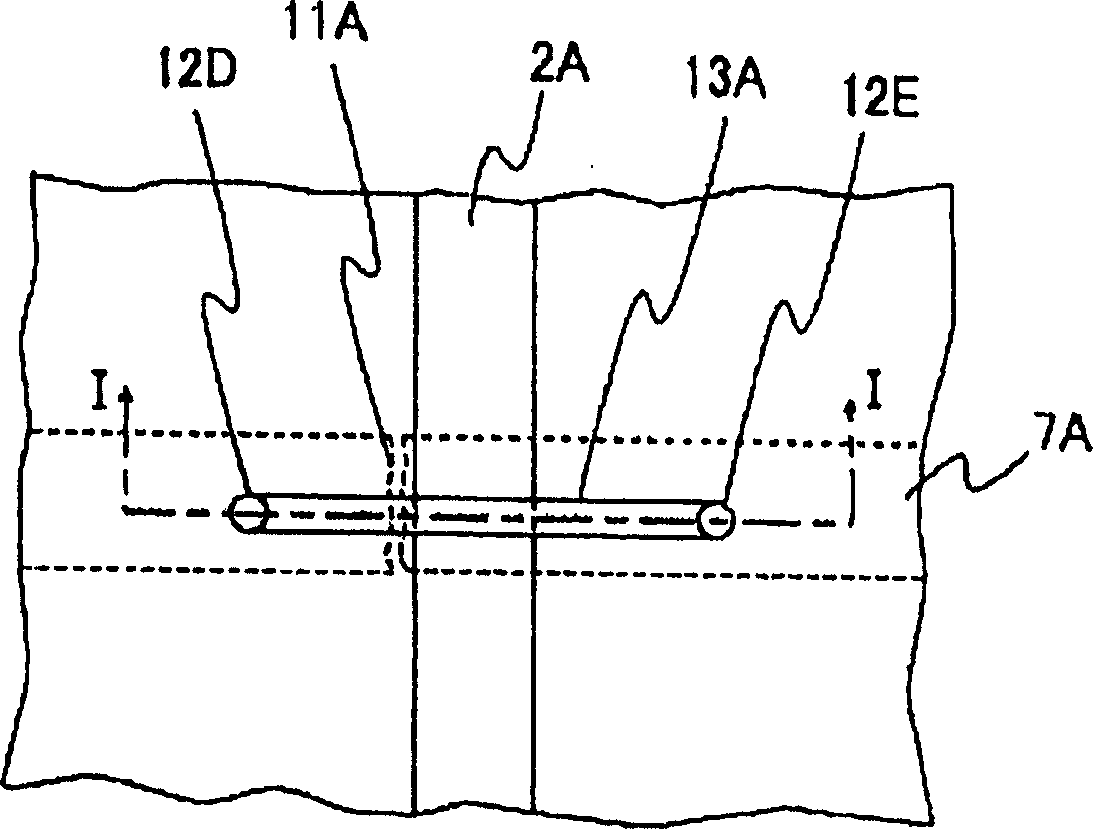

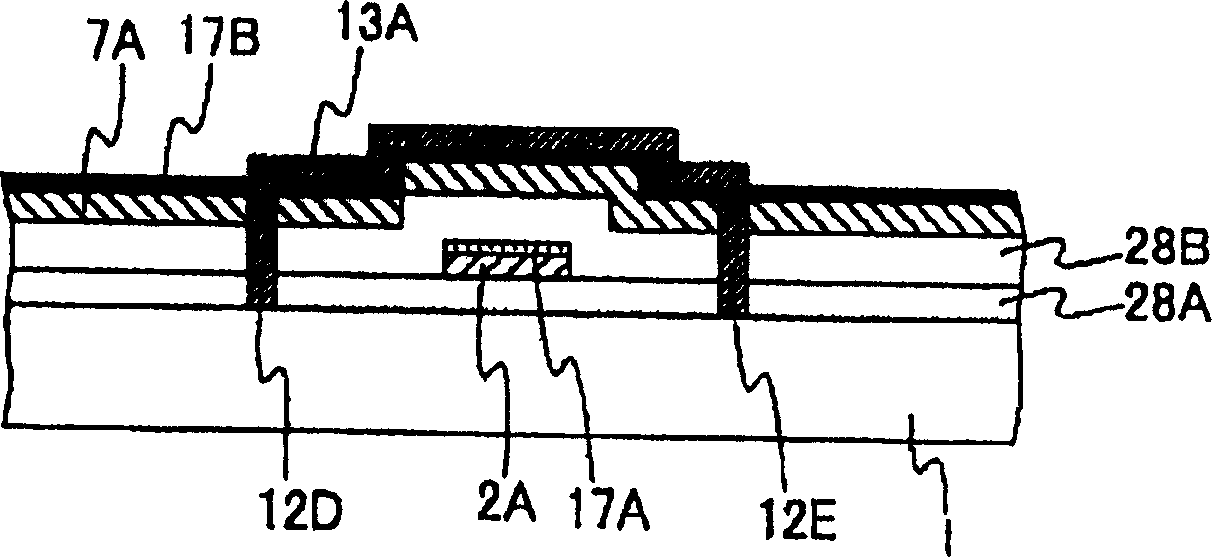

[0038] Referring to the accompanying drawings, a detailed description will be provided of preferred embodiments of the present invention. In order to make the present invention easy to understand, first, reference will be made to Figures 15A to 15D and 16A to 16C, provide descriptions of the method of manufacturing the active matrix liquid crystal display device except for the step of repairing the disconnection defect portion. Figures 15A to 15D and 16A to 16C show an example of a method of manufacturing an active matrix liquid crystal display device including an active matrix substrate (TFT substrate) with a process called back channel etch. ) TFT of inverted staggered (inverted staggered) TFT.

[0039] First, a metal film having a thickness of approximately 200 nm to 300 nm is formed on a transparent insulating substrate 1 such as a glass substrate, such as Figure 15A shown. This metal film is patterned by photolithography and etching techniques. Thus, scanning signa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com