Directional solidifying smelter

A technology of directional solidification and smelting furnaces, which is applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problems of large equipment investment, poor sealing performance of equipment, and poor metal purification effect, etc., so as to reduce the occupied area , Reduce the number of vacuum pumping stages, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

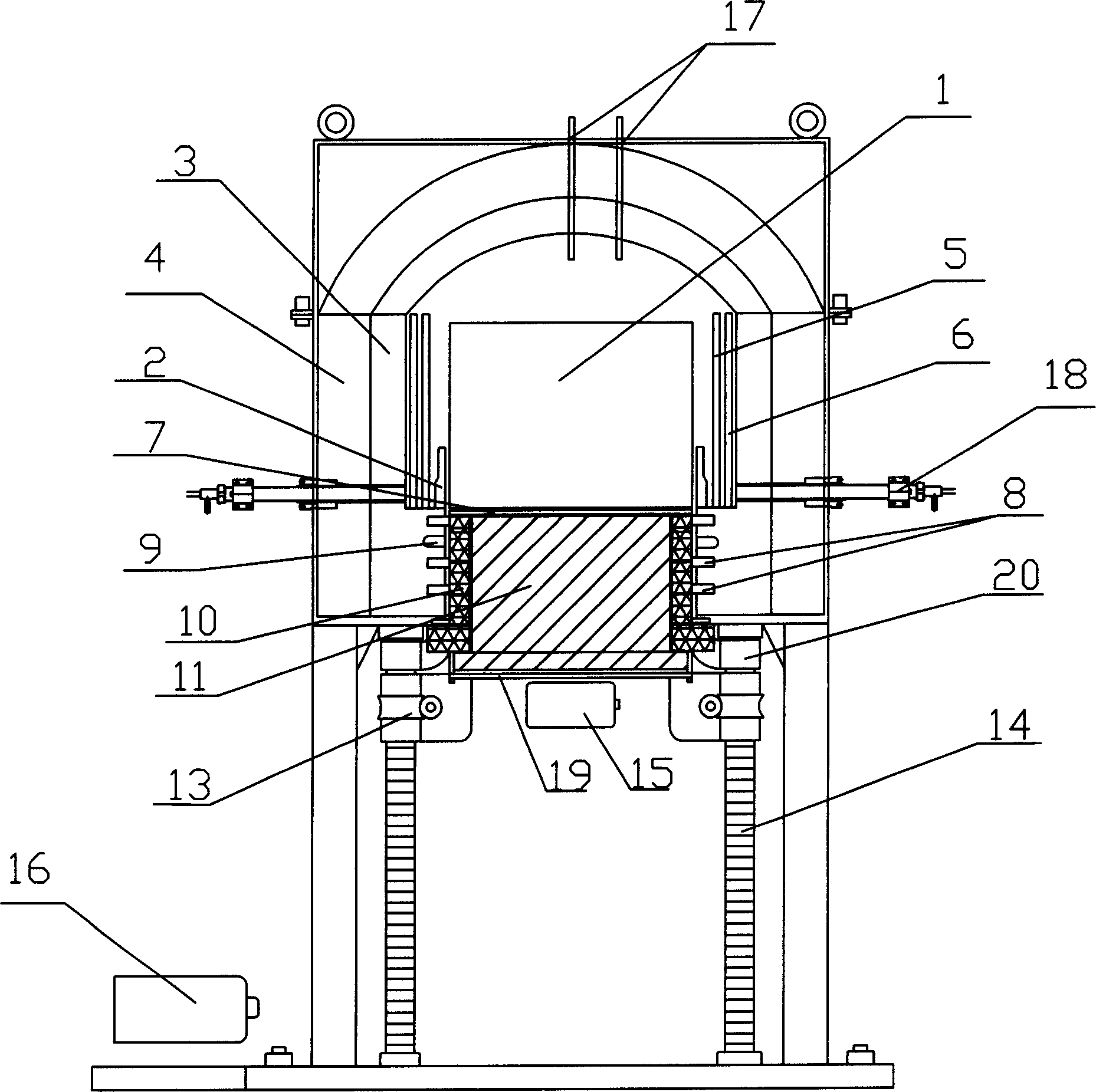

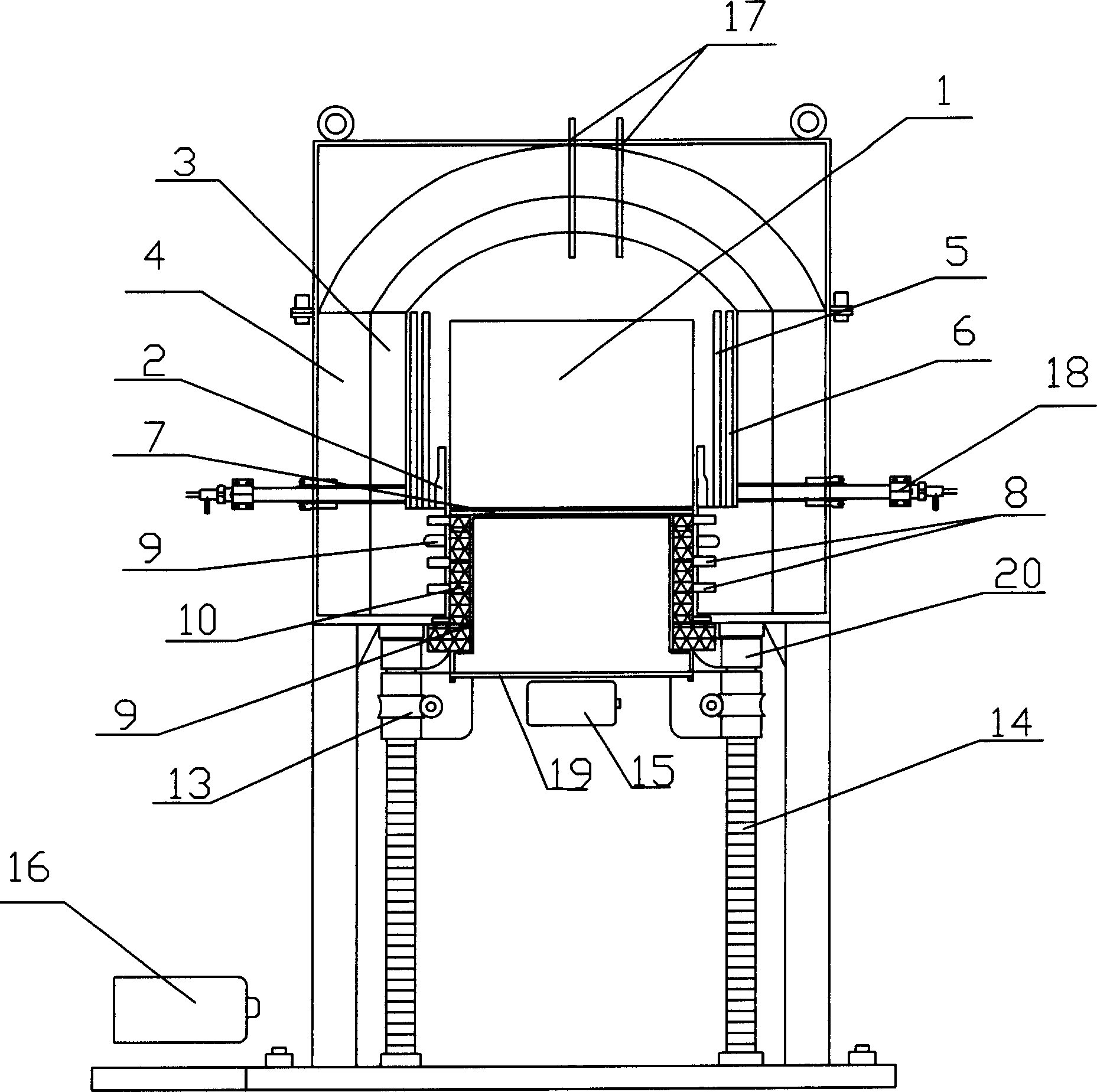

[0021] Such as figure 1 As shown in the directional solidification melting furnace, a graphite heater 5 is arranged on the outside of the crucible. The outside of the graphite heater 5 is successively a heat-insulating reflective layer 6, a refractory layer 3 and an insulating layer 4. The effect of the heat-insulated reflective layer 6 is to dissipate heat It is reflected back to the crucible 1 to prevent the loss of heat. A thermocouple 17 is arranged on the top of the crucible 1 to measure the temperature in the crucible 1. An inert gas and a thermocouple socket 18 are arranged on both sides of the crucible 1. During the process, the furnace temperature is as high as 2000°C, and graphite is easily oxidized at high temperature, so the furnace body is filled with protective gas such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com