Back light, light guiding plate, method for manufacturing diffusion plate and light guiding plate, and liquid crystal display device

A technology of liquid crystal display device and light guide plate, which can be used in lighting and heating equipment, light guide, diffusing elements, etc., and can solve problems such as ripples and display glare.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

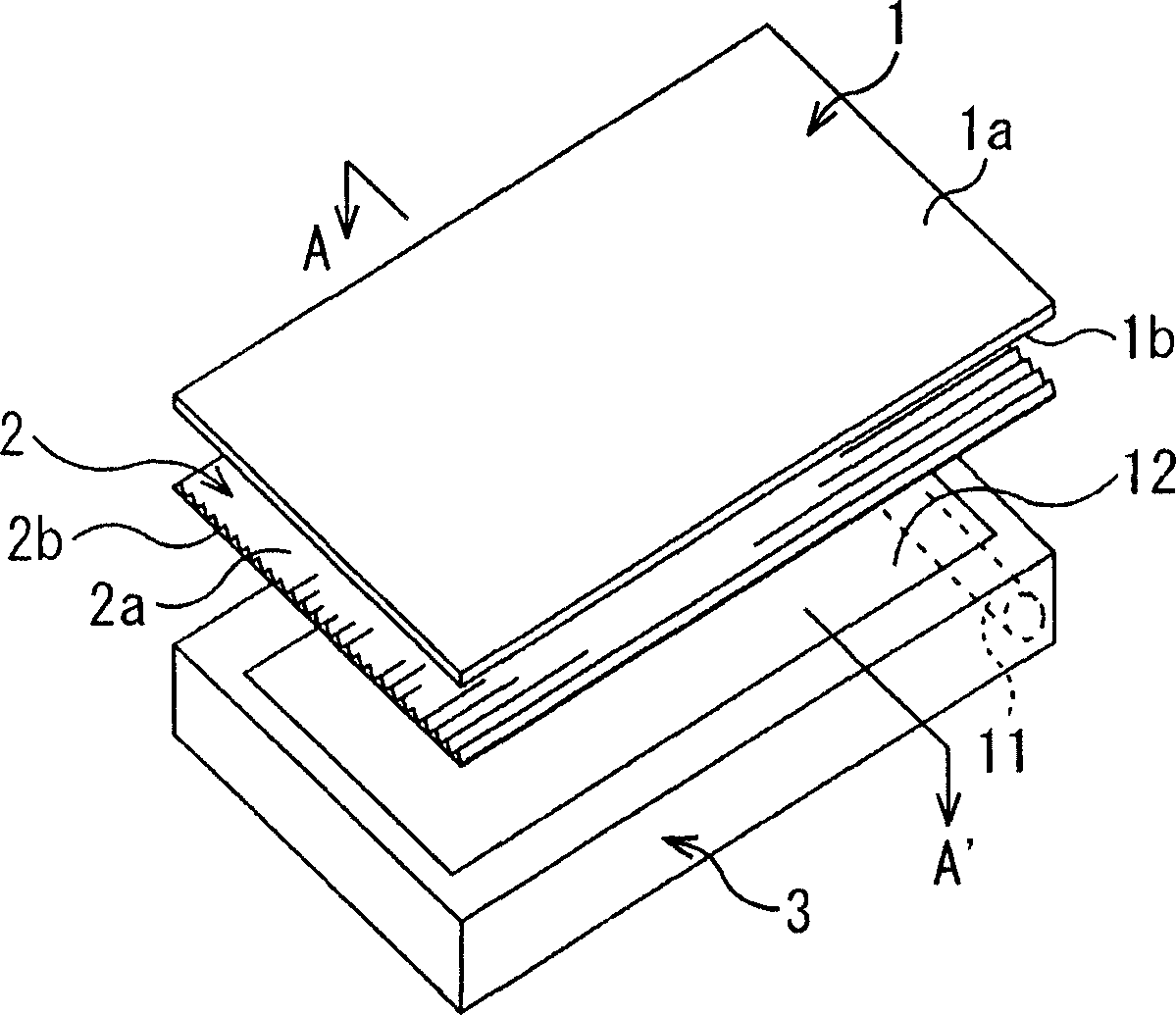

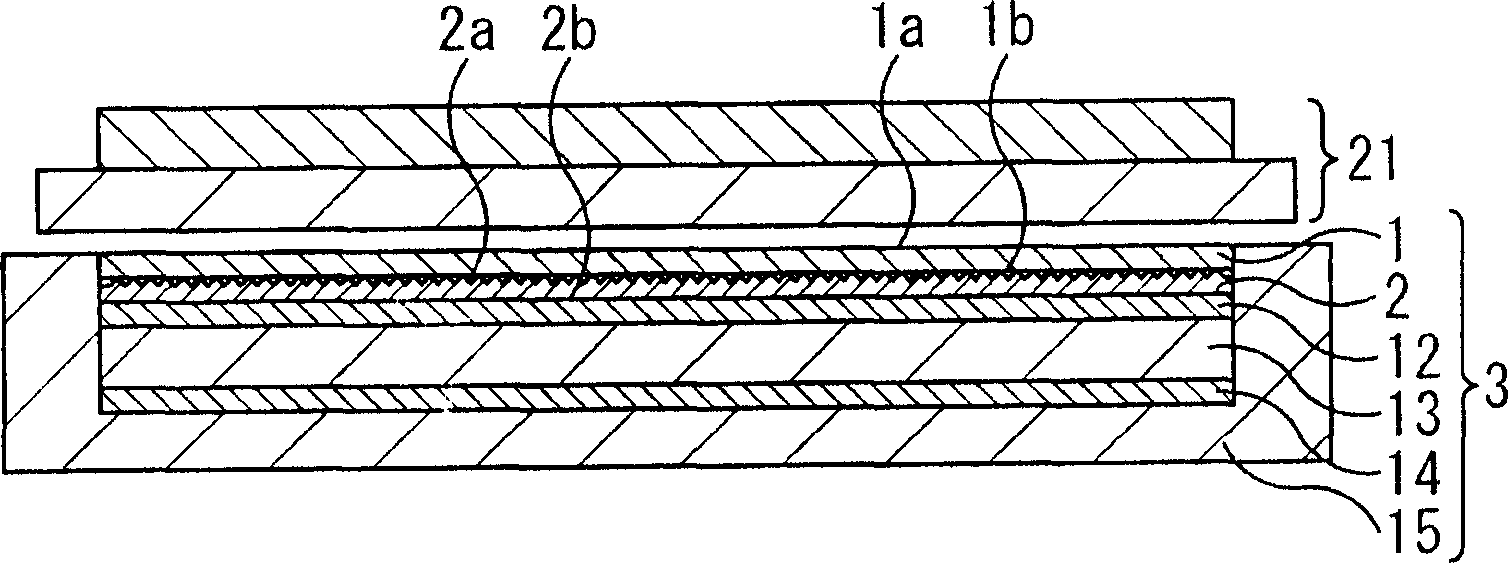

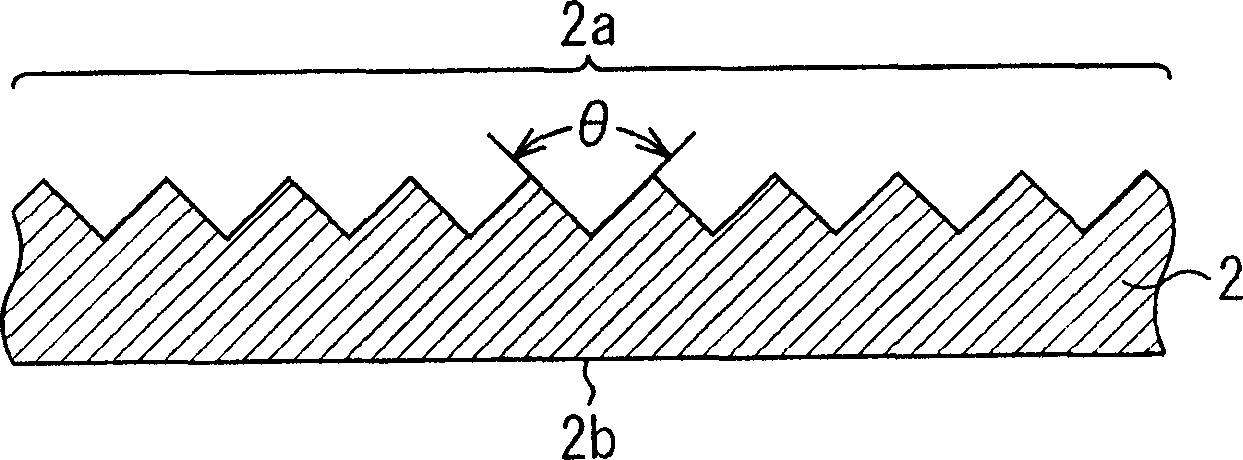

[0112] A first embodiment of the present invention will be described with reference to the drawings.

[0113] The type of backlight is a type in which, for example, cold cathode fluorescent lamps (CCFL) or light emitting diodes (LEDs) are arranged along and close to the side of a light guide plate formed of transparent synthetic resin for guiding light, and in which, for example, a plurality of cold cathode fluorescent lamps A type in which light sources are arranged parallel to each other. In the former, a diffuser is inserted between the light guide plate and the liquid crystal display device, and in the latter, a diffuser is inserted between a plurality of cold cathode fluorescent lamps and the liquid crystal display device, and the diffuser is used to diffuse light to Irradiate evenly onto the LCD display.

[0114] In Embodiment 1, a description will be given of a case where light sources such as a plurality of cold cathode fluorescent lamps are arranged in parallel with ...

Embodiment 2

[0184] The best example of implementing the light guide plate according to the present invention and the method of manufacturing the light guide plate and the backlight will be described in detail below with reference to the accompanying drawings.

[0185] Similar to the case of Embodiment 1 described above, the type of backlight is a type in which, for example, cold cathode fluorescent lamps (CCFL) or light emitting diodes (LEDs) are arranged along and close to the side of a light guide plate formed of transparent synthetic resin for guiding light, and A type in which light sources such as a plurality of cold cathode fluorescent lamps are arranged in parallel to each other immediately below a liquid crystal display. In Embodiment 2, a case where a light source such as a light emitting diode is arranged along and close to a side surface of a light guide plate formed of a transparent synthetic resin for guiding light will be described.

[0186] exist Figure 22 A light guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com