Vacuum thermal insulation material, thermal insulation apparatus using the material, and refrigerator-freezer

A technology of vacuum heat insulation and core materials, which can be used in heat preservation, household refrigeration equipment, and pipeline protection through heat insulation, and can solve problems such as heat insulation performance reduction and gas intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

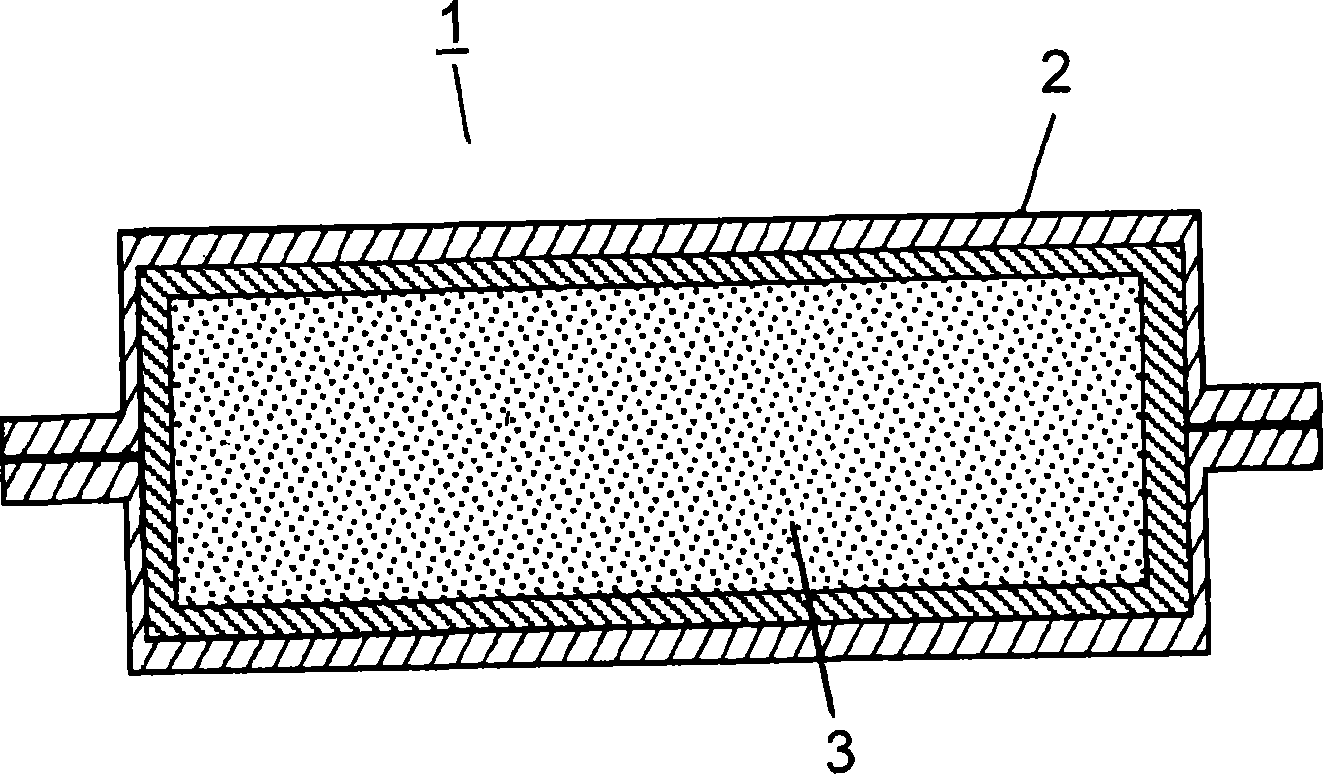

[0045] use Figure 1-Figure 4 Embodiment 1 of the present invention will be described. Such as figure 1 As shown, the vacuum heat insulating material 1 is a vacuum heat insulating material formed by covering a core material 3 with an outer coating material 2 and depressurizing the inside thereof to seal it.

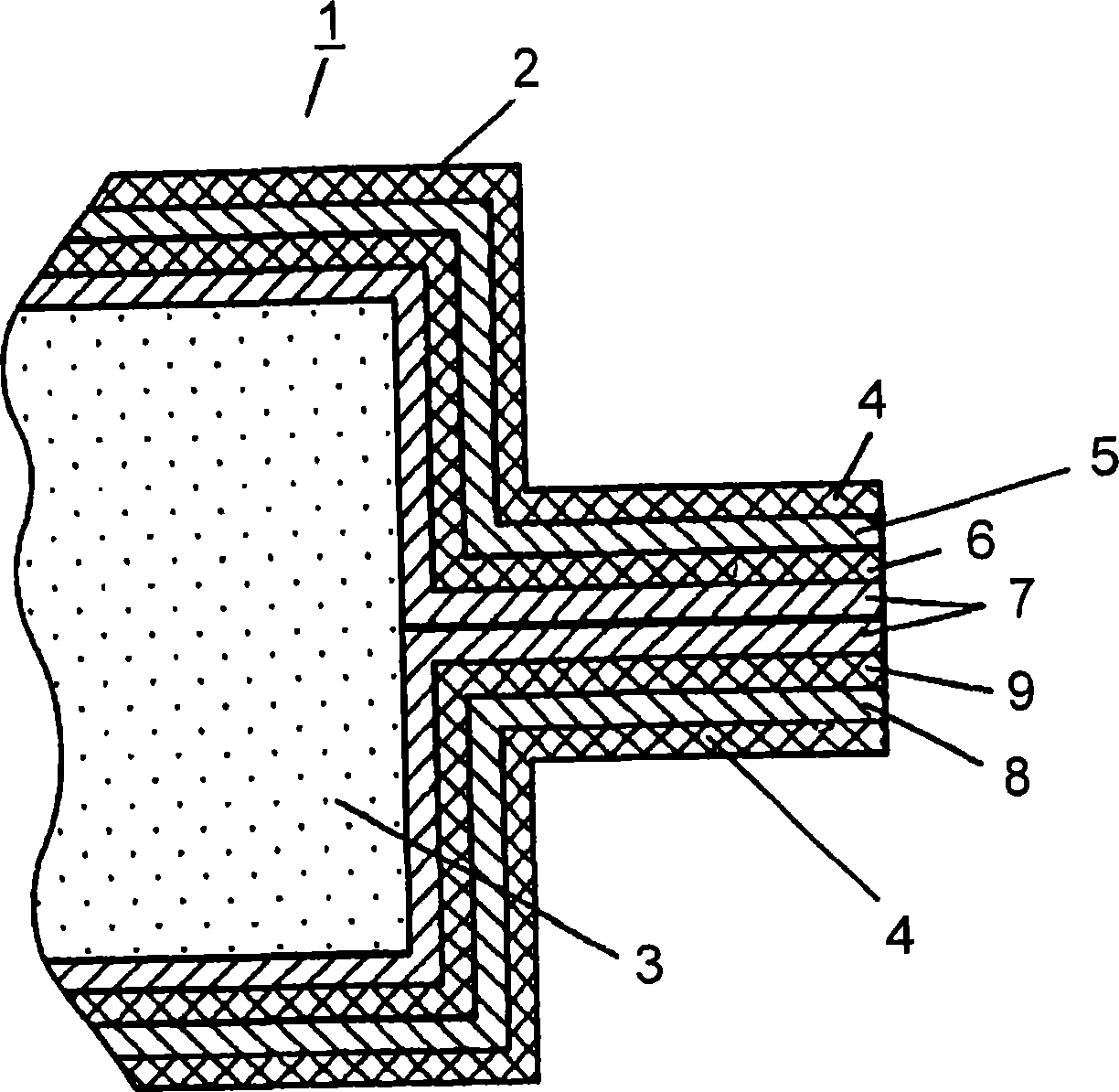

[0046] Such as figure 2 As shown, the outer covering material 2 is composed of a laminated film in which a metal foil and a plastic film are laminated, and a vapor-deposited plastic film. A laminated film formed by laminating a metal foil and a plastic film is composed of a nylon film 4 , a nylon film 5 , an aluminum foil film 6 , and a low-density polyethylene film 7 from the outside. The vapor-deposited plastic film is composed of a nylon film 4, a vapor-deposited polyethylene terephthalate (PET) film 8, a vapor-deposited PET film 9, and a low-density polyethylene film 7 from the outside. . Two sheets of laminated film are sealed in three directions to form a pouc...

Embodiment approach 2

[0065] Figure 5 It is a schematic diagram which shows the vacuum heat insulating material of Embodiment 2 of this invention.

[0066] exist Figure 5 In this case, a vacuum heat insulating material with a thickness of 11 mm is bent at 60 degrees on a groove portion 14 having a width of 12 mm and a depth of 4.5 mm, and the core material 15 outside the groove portion does not contact the groove portion 14 . That is, do not interfere with each other.

[0067] The operation and function of the vacuum heat insulating material constructed as above will be described below.

[0068] First, since one groove 14 is formed, the number of ridgelines generated at the edge of the groove, that is, at the boundary between the groove 14 and the surrounding ridges can be minimized. As a result, since the sharp stress acting on the film due to the presence of ridges can be suppressed, the area of micro cracks generated in the vapor-deposited laminated film can be suppressed to a minimum, so...

Embodiment approach 3

[0072] Image 6 It is a schematic diagram which shows the vacuum heat insulating material of Embodiment 3 of this invention.

[0073] Such as Image 6 As shown, a vacuum heat insulating material having a thickness of 11 mm is bent at 90 degrees on a groove portion 16 having a width of 12 mm and a depth of 6.5 mm, and the core material 17 outside the groove portion does not contact the groove portion 16 . That is, do not interfere with each other. Furthermore, the groove portion 16 exists on the side of the laminated film surface on which vapor deposition has been performed, and this portion is bent inside.

[0074] The operation and function of the vacuum heat insulating material constructed as above will be described below.

[0075] First, the part of the film where the stress acts the most due to bending is the vapor-deposited laminated film at the bent portion. Because it is a thin film on which particles are vapor-deposited and has flexibility, it is similar to the cra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com